3Dnatives’ Startup of the Year: The Choice is Yours!

Each month, 3Dnatives spotlights a startup that is pushing the boundaries of 3D printing. As 2025 draws to a close, it’s time to choose which of these innovators will be crowned our official Startup of the Year. And the decision is in your hands: cast your vote before December 31st using the poll on the right side of your screen. To help you make your choice, we’ve put together a recap of every featured company. Whether they’re pioneering new printing techniques, developing groundbreaking software, or creating devices that make a real difference in people’s lives, these startups have all achieved something remarkable. Discover them below!

SelectAM: Developed A Platform for Identifying Which Parts to 3D Print

The Finnish startup SelectAM devised a fully automated, AI-based platform capable of identifying the most appropriate parts to 3D print. Based on provided data, SelectAM estimates costs, production time and savings compared to using traditional techniques. The company’s mission is to help companies make the right parts for the right reasons. The company essentially offers an “automated 3D printing expert,” and its platfor m is technology-agnostic, meaning they can set up any type of technology in the estimation profile.

Read our interview with SelectAM HERE.

(Photo Credits: SelectAM)

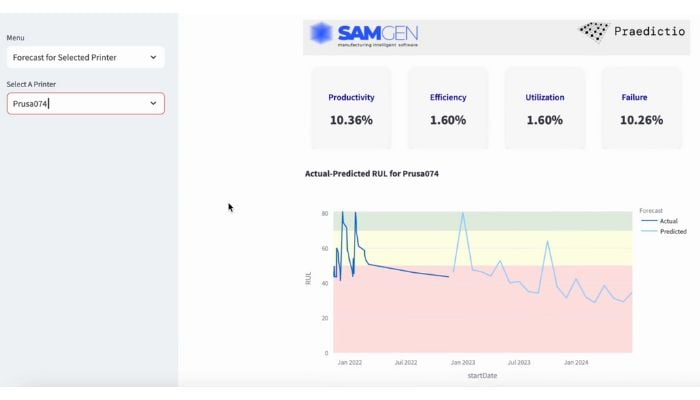

SAMGEN: Designed A Predictive Software to Optimize Printer Maintenance

SAMGEN, a startup out of Berlin, developed PRAEDICTIO, a cloud-based software that can help accurately predict the maintenance needs of 3D printers. It uses advanced algorithms to continuously monitor and assess the wear and tear of key components, such as the heating bed, fans, and sensors. The technology transforms traditional maintenance into a data-driven approach, enabling customers to maximize their equipment’s efficiency. With RUL Remaining Useful Life) predictions, users gain insights into how long each printer and its components are likely to function optimally. This helps them plan maintenance with their service provider, avoid unnecessary downtime, and save costs.

Read our interview with SAMGEN HERE.

(Photo Credits: SAMGEN)

LEAM: Uses Continuous Light Spectrum to Melt Material for LFAM

A spin-off from the Technical University of Munich, LEAM created the DEMEX system, an add-on for large-format 3D printers. The system combines LED emitters and infrared cameras distributed around the extruder nozzle. Using the LED emitters, the DEMEX system can heat the substrate in a highly targeted and localized manner in front of the nozzle, guaranteeing perfect welding of the layers. Additionally, a closed control circuit with infrared cameras ensures the desired target temperature is reached. So, instead of the maximum z-resistance of 60% previously achievable, the workpiece can now reach 100% of the resistance specified in the material manufacturer’s data sheet – in all directions!

Read our interview with LEAM HERE.

LEAM’s DEMEX system improves the layer density of extra-large 3D printed parts. (Photo Credits: LEAM)

3D Architech: Developed A Gel-Based Metal 3D Printing Technique

3D Architech has a proprietary gel-based 3D printing technology for metal that can achieve micron-scale features as fine as 10 microns. The process begins with a lithography-based approach to create gel structures with the desired architecture. Then, through a specialized procedure, these gel structures are converted entirely into metal or alloy parts. The technology allows for advanced microarchitecture design, significant cost reductions, and high throughput. For now, 3D Architech is focusing on the cooling, energy, and manufacturing sectors. The company is based in Japan and the United States.

Read our interview with 3D Architech HERE.

(Photo Credits: 3D Architech)

Addimetal: Makes Metal Binder Jetting Accessible

Addimetal is a French startup with a mission to deliver repeatable and reliable metal binder jetting to its users. The company developed its own 3D printer, the K2-2, that is designed to be “plug & play.” The machine is completely open in terms of materials and binders, and it’s optimal for research or industrial environments. Plus, the system anticipates and manages the challenges associated with sintering by developing tools that simplify part preparation and monitoring. Orion, Addimetal’s software, offers advanced slicing, a user-friendly interface, and production monitoring and controlling, allowing metal binder jetting to be more approachable.

Read our interview with Addimetal HERE.

(Photo Credits: Addimetal)

FIDENTIS: Redefining Dentures with Multi-Material 3D Printing

A spin-off from the Fraunhofer IGCV institute, FIDENTIS garnered attention with a multi-material 3D printing solution designed for telescopic prostheses. The company’s technology combines laser powder bed fusion with a robotized system which allows two or more alloys to be combined in a single component. The complexity of multi-material L-PBF requires extreme precision at every stage, so FIDENTIS developed solutions that structure and stabilize the entire process. Their mission is to support dental laboratories in the industrialization of high-quality prostheses.

Read our interview with FIDENTIS HERE.

(Photo Credits: FIDENTIS)

S.A.M: 3D Prints Tokens for Data Protection

In the age of the internet, data security is critical. That’s why the French startup S.A.M (Signature & Authentification des Matériaux) aims to fight counterfeiting and protect sensitive data through 3D printed “tokens.” These physical keys store confidential information like proof of ownership, serial numbers, or secure access, allowing for simple, autonomous, and offline protection. To print them, the user only needs a double-headed FDM printer, a spool of S.A.M coding material, a dedicated application for generating G-codes and a physical 3D token decoder.

Read our interview with S.A.M. HERE.

(Photo Credits: S.A.M)

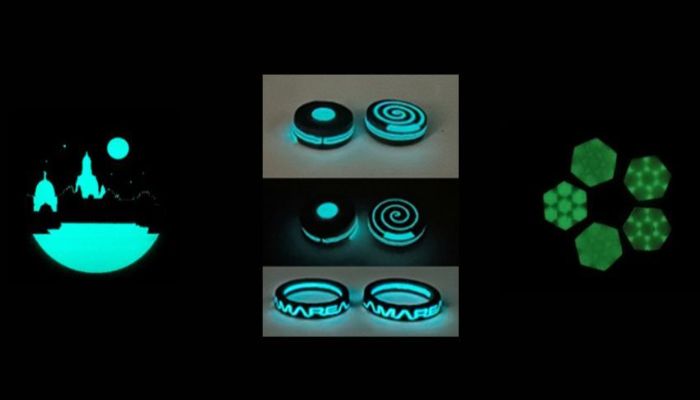

AMAREA Technology: Developed Multi Material Jetting for Thermoplastics

AMAREA Technology creates additive manufacturing machines for high-performance materials, such as technical ceramics, metals, composites, and polymers. What’s unique about the German startup is that it is aiming to combine these materials via its technology, Multi Material Jetting. The process works by depositing thermoplastic polymer droplets that are filled with functional materials such as ceramics, metals, glasses, or composite materials in powder form. The material melted locally and then deposited as individual droplets via the print heads, immediately fusing together and solidifying. Importantly, by depositing material drop by drop, materials from different classes can be deposited selectively and combined within complex geometries.

Read our interview with AMAREA Technology HERE.

(Photo Credits: AMAREA)

Parastruct: Drives Sustainability with Circular Advanced Manufacturing

Based in Austria, the startup Parastruct has the goal of making the construction sector more affordable, sustainable, and tailor-made. To this end, it has developed a method called Circular Advanced Manufacturing, which enables it to create optimal printing materials. Specifically, it mixes biogenic waste and minerals with low-carbon binders. These can then be 3D printed using the powder binding process.

Read our interview with Parastruct HERE.

(Photo Credits: Parastruct)

Augmental: Created Mouthpad^ Device to Make Tech Accessible

Augmental has developed an innovative device for anyone with a physical disability, particularly those with limited hand mobility. It has designed a touchpad that can be placed in the mouth to control a computer, tablet, or phone. The device, called MouthPad^, is 3D printed using SLA technology with dental-grade resin. It is currently available for purchase.

Read our interview with Augmental HERE.

(Photo Credits: Augmental)

Gameet: Produces Microdevices To Optimize the Selection and Fertilization of Gametes

Argentinian startup Gameet has developed a micro device using SLA 3D printing that could optimize gamete selection and fertilization. The aim is to facilitate current assisted reproduction treatments, which are often lengthy and require several steps. The startup has just completed the development of its first biocompatible device, which it has successfully tested on cattle. The next step, of course, is to move on to clinical trials on patients. This is an exciting new application for the medical sector!

Read our interview with Gameet HERE.

(Photo Credits: Gameet)

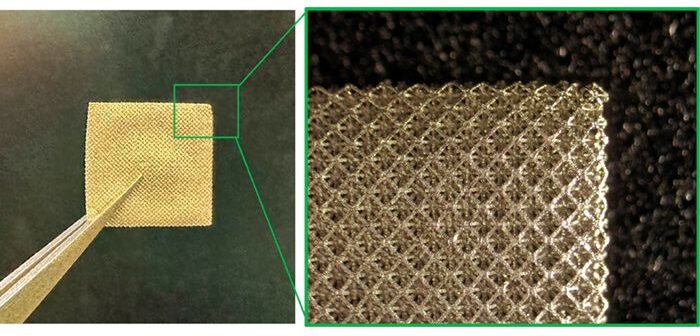

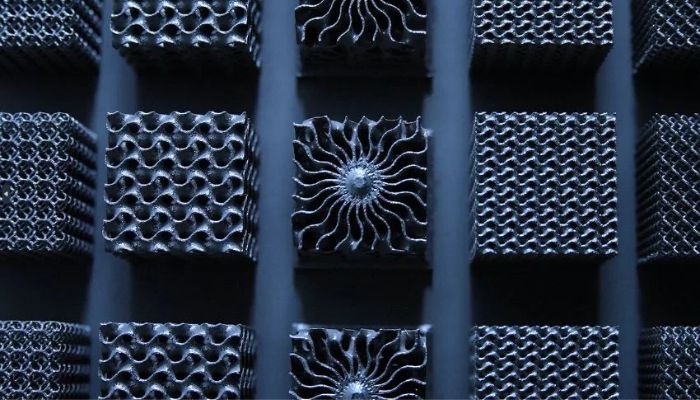

AM3L: Produces Porous Metamaterials with Metal 3D Printing

The last startup on our list is French and focuses on porous metamaterials. AM3L uses metal additive manufacturing to create structures with customized, controlled, and verified architecture. It seeks to control the porosity of each part produced rather than its density. The startup can thus offer different properties in a single structure by manipulating its architecture.

Find out how it does this by reading our interview HERE.

(Photo Credits: AM3L)

Be sure to cast a vote for your favorite using the poll on the right side of your screen! What do you think of these startups? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.