3Dnatives Lab: Testing the UltiMaker S8

UltiMaker S8 test: a logical update, a natural progression. Two years after testing the S7, it’s the UltiMaker S8’s turn to go through our test. If you haven’t yet read our review of the S7, we invite you to take a look HERE, as the S8 is a logical continuation of the S7.

When you see the S8 for the first time, you immediately get a feeling of déjà-vu. And with good reason: on the outside, nothing changes from the S7. Same format, same finish, same ports, same screen, same accessories. The only differences visible to the discerning eye:

- The new Printcores AA+ and CC+, offering higher extrusion throughput;

- The new extruders borrowed from Factor 4, the manufacturer’s top-of-the-range industrial printer;

- The S8 badge on the front of the machine, to the right of the display;

- New 3D-printed clips to hold PTFE tubes in the printer;

- The vertical bar on the chassis, which changes from white to black (a purely aesthetic detail).

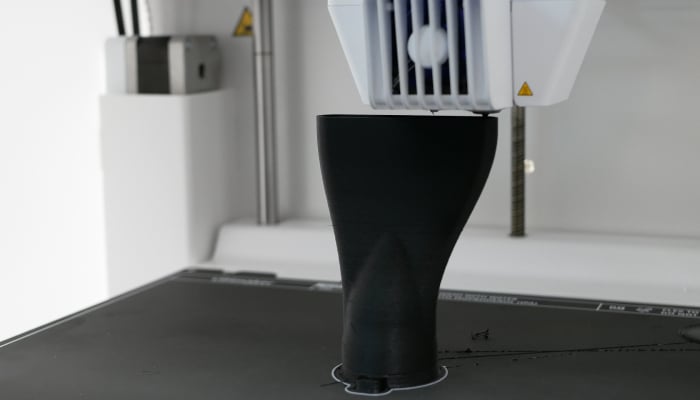

The hardware structure of the UltiMaker S8 is the same as that of the S7. Same chassis, same mechanics, same magnetic platen system with flexible foil, same motors. The real differences are invisible to the naked eye: they’re on the printed circuit board, and above all in the on-board firmware, which has been extensively reworked to boost print speeds without compromising quality.

So we’re not going to repeat a complete test here, as if everything were new, because, as you’ll have understood, it’s not. For everything concerning handling, installation and ergonomics, we refer you to the S7 test, which is still perfectly valid and up to date.

But this is not a criticism. Quite the contrary, in fact.

The UltiMaker S8 visually resembles the S7.

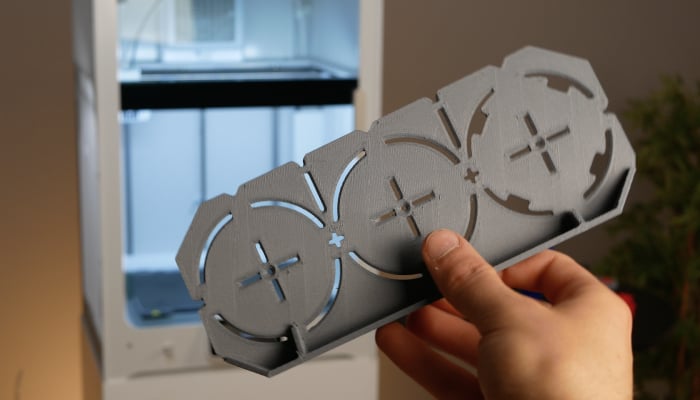

Since 2019, with the introduction of the S3 and then the S5, UltiMaker has adopted a common hardware architecture across all its professional printers. The S6, S7, S8 and even the Factor 4 share a very similar technical base, with many components identical or compatible. This has two major advantages:

- A streamlined ecosystem, facilitating spare parts management and maintenance, since UltiMaker controls its supply chain and has been producing the same references for years.

- Simplified technical training, especially for dealers, integrators and after-sales service technicians, who don’t have to relearn a machine with each new generation.

In a professional context, this technical continuity is invaluable. Not only does it minimize downtime in the event of a hardware problem, it also standardizes a print farm without multiplying the number of part numbers, tools or maintenance procedures. A safe bet, even if it implies a form of technical conservatism.

So, what does this S8 offer? A clear acceleration in performance made possible by the new firmware, a redesigned Printcores kit, and software improvements on the Cura and Digital Factory sides. Nothing revolutionary, but a well-calibrated evolution in line with what UltiMaker has been offering for years: reliability, precision and a solid software environment.

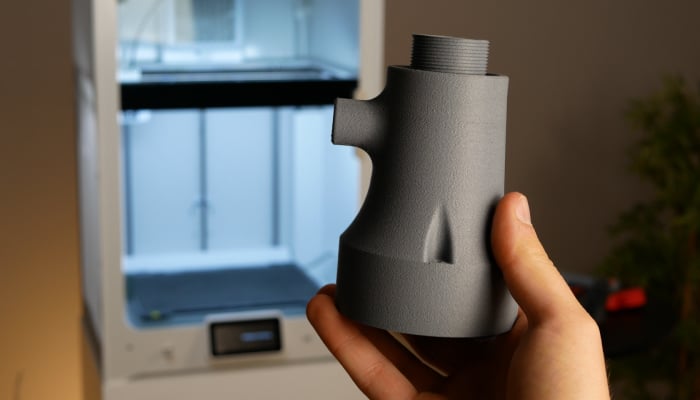

The S8 uses the same extruder as the Factor 4.

Bundle & Printcores: A Discreet but Logical Change

Unlike the S7, which came with three Printcores (two AA and one BB), the S8 offers just two, like the S6. But the duo supplied is more strategic: a PrintCore AA+ for fine details and classic prints, and a PrintCore CC+ for reinforced, abrasive or composite materials.

The printer still uses the same type of interchangeable hotends called “Printcores,” but introduces a new version + which boasts a higher extrusion rate.

This configuration is more focused on hardware performance and industrial flexibility. Where the BB was often under-utilized, UltiMaker adapts to the reality of professional uses, via its statistical analyses based on real usage data: today, complex bi-material prints with solubles are marginal.

On the S6, UltiMaker chose to include two AA+ Printcores, abandoning the BB. On the S8, the AA+/CC+ duo offers an ideal balance for getting started straight away with technical materials, enabling standard materials to be combined with composite-reinforced materials.

For the rest, the equipment supplied with the S8 is identical to that of the S7: same wiring, same accessories, same automated calibration, same integrated air filter. Nothing new to report here, which is rather good news.

UltiMaker S8 Performance: Speed, Without Sacrificing Quality

Where the S8 really stands out is in speed. The new firmware has enabled UltiMaker to optimize the entire production chain: management of accelerations, trajectories, travel speeds and motor control. The results are tangible: in our test, a part that took just over 2 hours on the S7 was printed in just 34 minutes on the S8!

This gain doesn’t come from hardware magic. It’s proof of the effectiveness of our work on firmware and software optimization. That said, not all parts will benefit from such a reduction: gains depend on geometry, material and printing parameters.

Smaller parts will benefit least from this performance, since the print start-up process time is the same as with the S7, and remains rather long. According to UltiMaker, this is the price to pay for greater reliability.

But in favorable cases, the S8 becomes a much more competitive production machine, especially in industrial environments.

Cura & Digital Factory: A Refining Experience

Since the S7 test, both Cura and the Digital Factory have been maintained and regularly updated. Cura can now be used in the cloud, directly from a browser, without the need to install any software. This is a very welcome development in multi-machine, educational and corporate environments. Please note, however, that this online slicer is reserved for paying Digital Factory users.

Like all UltiMaker printers, the UltiMaker S8 uses the Cura slicer.

During our test, we noticed a frustrating behavior. When the file was sliced for filament with no predefined (generic) color, printing was blocked without any clear explanation on the machine or in Cura. Only Digital Factory reported the problem, via a rather blunt pop-up. The problem was that the printer refused to print on the pretext that the material used in the slicing and the actual material were different (when in fact it was the same material but of a different or unspecified color). After reporting the problem to UltiMaker, the behavior was corrected within a few weeks. An encouraging sign: user feedback is taken into account, and software evolution is rapid.

Conclusion

- 3D Printer Features and Accessories 9/10

- Software 9.5/10

- Print Quality 9/10

- Ease of Use 10/10

Pros:

- Improved print speed

- Regular software and firmware updates

Cons:

- High price (around €8,000)

- Still slow to start printing

UltiMaker isn’t trying to reinvent everything with the S8. And that’s probably a good thing. The S7 was already one of the most accomplished professional 3D printers on the market. The S8 takes exactly the same foundation, adds increased speed, optimized firmware, a more relevant Printcores duo, and benefits from an ever-improving software ecosystem.

Where some expect a radically different machine, the S8 plays the mature, efficient card. It’s not a revolution, but a well-thought-out evolution. For professionals already equipped with UltiMaker, it’s a natural transition. For those still hesitating, it’s a clear signal that the UltiMaker platform is mature, stable and ready for production.

And if you’re looking for more details on the user experience, accessories or machine interface, don’t hesitate to consult our full test of the S7, which remains entirely relevant. To learn more about the UltiMaker S8, check out the company’s website HERE.