3Dnatives Lab: Testing the Raise3D RMS220, The First SLS Printer from Raise3D

Raise3D is celebrating its tenth anniversary this year. Known for its professional FDM printers, particularly the Pro3 and E2 series, and more recently for its DF2 and DF2+ resin systems, the brand is taking another major step forward with the arrival of its first SLS printer: the Raise3D RMS220. This launch symbolizes a strategic turning point for the manufacturer, which aims to establish itself as a comprehensive multi-technology player in the professional segment, capable of offering filament deposition, photopolymerization, and now selective laser sintering.

Previewed at TCT Asia 2025, the RMS220 is positioned in the compact SLS machine market, a segment previously dominated by players like Formlabs and Sinterit. Raise3D brings a new approach: a faster, more open, and above all, more affordable system without sacrificing print quality. The machine will be available for pre-order by the end of 2025, with official commercial launch in the first quarter of 2026.

We had the opportunity to test a pre-production unit directly at Raise3D’s facilities in Portugal. This version wasn’t yet final: some parts were 3D printed, and other features weren’t yet activated. However, this test provides a clear idea of the manufacturer’s ambitions and the positioning of this new platform.

Test Conditions

During our visit, the RMS220 was already installed and calibrated by the Raise3D team. This allowed us to focus on the software, mechanical operation, and printing performance, without having to go through the assembly or network setup stages.

This was an advanced prototype, a pre-production machine already very close to the final model, but still exhibiting some characteristics typical of this development phase. Several internal components, such as the hinges, support arms, grids, and fasteners, were still 3D printed—a practical solution for accelerating fine-tuning before production.

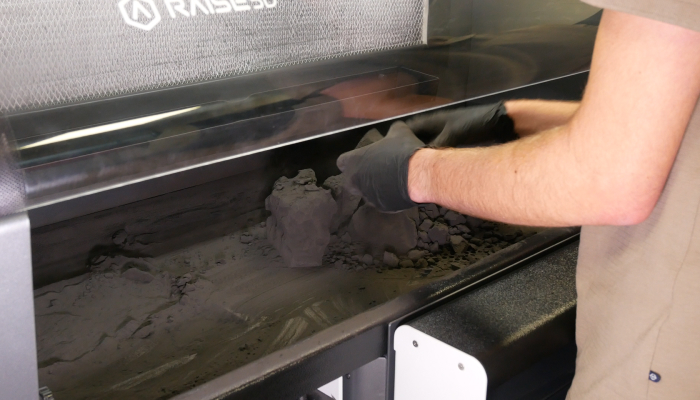

The build unit is easily maneuverable from the printer to the cleaning station, thus facilitating handling for increased productivity.

The active cooling system of the build unit was not yet operational during our test, nor were its external power supply and controls. These controls will allow the commercial version to manage temperature and build plate height without relying on the cleaning station, a real gain in flexibility for operators.

Regarding materials, our tests were limited to PA11, the only one available on site. Raise3D also showed us samples printed in PA12 and TPU, demonstrating the machine’s versatility, but we were unable to produce them ourselves.

Finally, several features were still being integrated and optimized, notably the ability to clean the printer in less than 45 minutes thanks to a quick-release system. This pre-production context is important to keep in mind when reading this review, as the final version of the RMS220 is expected to benefit from significant hardware and software refinements.

Technical Characteristics and Design

With a footprint of just 0.58 m², the RMS220 is designed to be compact and easy to integrate into a professional environment, while offering a generous build volume of 220 × 220 × 350 mm, or approximately 17 liters of usable volume. This is a capacity more than 2 times greater than that of a Formlabs Fuse 1+ and close to some larger industrial machines.

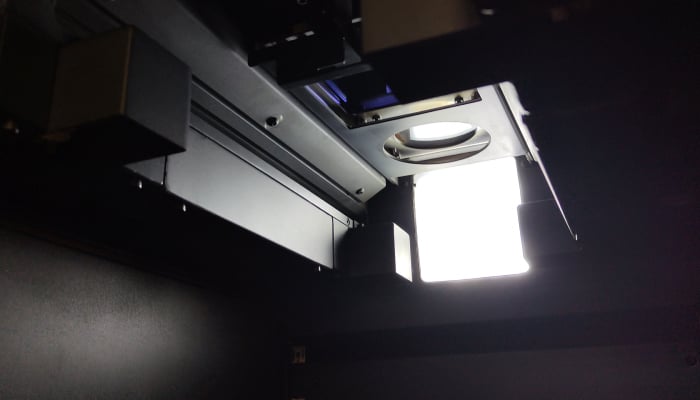

Raise3D has opted for a 75 W fiber laser (1064 nm wavelength), coupled with a fast galvanometer and F-theta optics. This combination allows it to achieve a scan speed of 30,000 mm/s, significantly higher than the market average (often between 12,000 and 20,000 mm/s).

The choice of a fiber laser is a strong technical decision by Raise3D, and it offers several tangible advantages. First, this type of laser requires significantly less maintenance than a traditional CO₂ system: it does not require regular maintenance of the laser tube which can leak over time, and its lifespan is significantly longer. Second, the beam generated by a fiber laser offers superior stability and homogeneity, guaranteeing consistent quality across the entire build area. Finally, this technology stands out for its energy efficiency. Whereas a CO₂ laser often requires an external liquid cooling system or very powerful and noisy air ventilation requiring a dedicated electrical installation, the RMS220, which consumes on average 1100W, is satisfied with a simple 230V/16A socket, without the need for a specific installation. This is a significant advantage for organizations looking to integrate a high-performance SLS printer without modifying their existing electrical infrastructure.

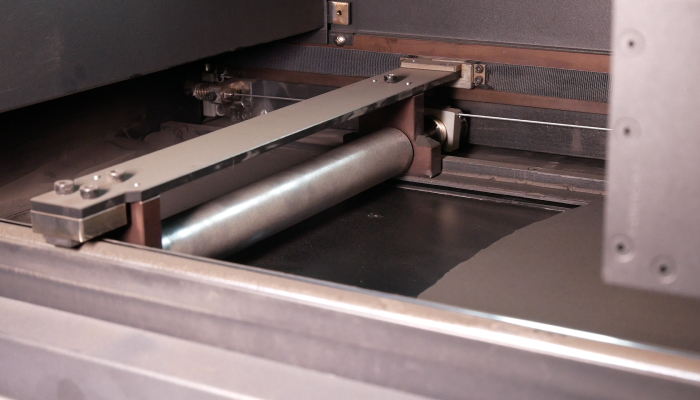

Powder management is handled by a hopper and a recoater, ensuring uniform layer distribution, essential for consistent prints. The Build Unit, which is completely removable, allows a new job to be quickly started while the previously used job cools down outside the printer. In its final version, it will incorporate active cooling that will bring the vat temperature back down to 15 to 20 minutes after printing, compared to several hours currently. The version we tested only allowed cooling with the build unit in the printer or cleaning station, but the final version will integrate a power system and a dedicated control panel, allowing separate cooling.

The RMS220 also stands out thanks to its integrated nitrogen generator, a first in this price range. Combined with an external compressor, it allows printing in a controlled atmosphere, limiting oxidation and significantly reducing the need for fresh powder—up to 10% refreshment depending on the material, compared to 50% in air mode. Users can, however, choose to print in open air for greater simplicity.

The entire system is controlled via a large touchscreen, coupled with an internal camera for remote monitoring and full Wi-Fi/LAN connectivity. On the unit tested, some internal fasteners were still screwed in, but the final version will offer quick disassembly, with a powder-resistant coating in the printing chamber for easier cleaning.

Software and User Experience

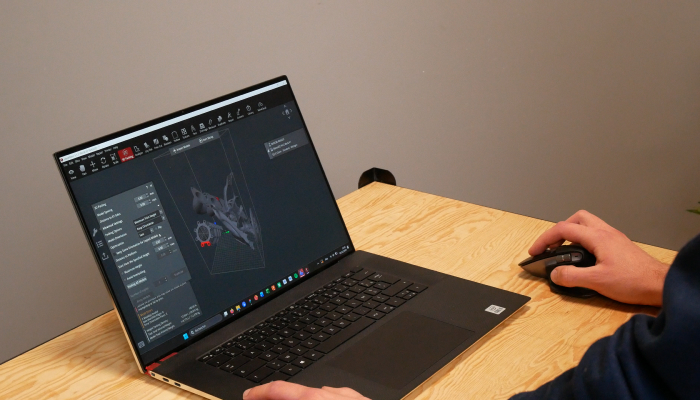

On the software side, the RMS220 relies on ideaMaker, the slicer developed by Raise3D. For this project, the software has been extensively adapted to SLS technology, and we were able to try a beta version that integrates several specific tools.

RAISE3D uses IdeaMaker, its own slicer for all its printers, FFF, DLP and now SLS.

Among them is the 3D Packing function, the equivalent of automatic nesting, which optimizes the placement of parts within the print volume. The algorithm works well and offers a good infill rate, although automatic rotation and collision detection could still be improved. Another new feature is predictive thermal analysis: this tool highlights areas of the powder bed likely to experience temperature variations, thus helping to prevent warping before a job is started. Finally, ideaMaker now generates detailed post-slicing reports, including infill density, estimated weight, and a complete analysis of production costs. This set of indicators is invaluable for professionals looking to better plan their production and material costs.

The machine’s interface is smooth and well-designed. Automatic calibration of the four infrared heating zones ensures a uniform temperature across the entire bed surface.

However, there is one minor ergonomic drawback: the touchscreen is not very responsive when wearing gloves, a detail that can be problematic in environments where dust often necessitates hand protection. On our unit, we sometimes had to remove our gloves to interact with the interface.

The RMS220 features a color touchscreen with an intuitive interface for controlling the machine.

Finally, Raise3D plans to integrate RaiseCloud with the RMS220 by mid-2026. This integration will allow for the remote monitoring of multiple printers, batch scheduling, and print history management from a centralized dashboard – a welcome advancement for production environments.

Performance and Workflow

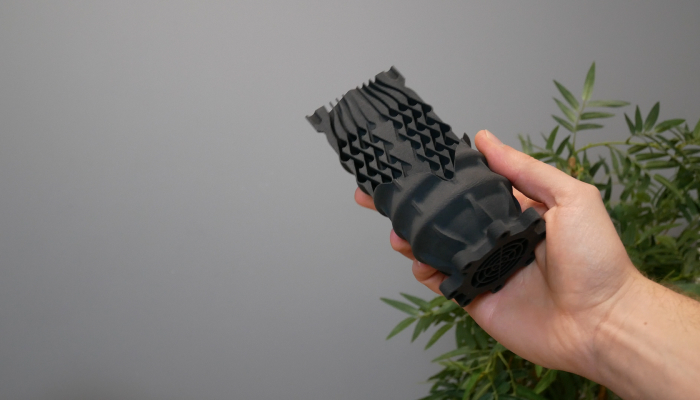

Prints made with PA11 revealed dimensional accuracy of approximately ±0.2 mm, perfectly consistent with professional SLS standards. The resulting parts exhibit excellent finish, homogeneous surfaces, and controlled internal density.

Raise3D announces a productivity of up to 2.2 L/h with PA12 at 20% packing density, or up to 5 kg of parts per day—realistic figures based on our tests. The removable Build Unit saves valuable production time by allowing a new cycle to be started while the previous one cools or undergoes cleaning.

In terms of materials, Raise3D adopts a two-tiered approach, offering a good balance between openness and security. More advanced users can opt for a full license, priced at approximately €5,999, which unlocks all printing parameters and allows them to work with any powder, including those from other manufacturers. For those who prefer a more structured approach, Raise3D also offers a material card system, sold for around €120 per 10 kg. These cards temporarily activate features similar to the full license, allowing experimentation with specific powders before purchase or the production of small batches with third-party materials. This hybrid strategy allows users to maintain the machine’s flexibility while ensuring print reproducibility, regardless of their level of expertise.

Raise3D is already working with partners like Fabulous, for an FDA-certified PA, and other materials (PA6, PA-CF, PP, TPU) should quickly enrich the base. These materials will be part of the third-party materials program, where they are provided with material cards, ready to be used in the RMS220, without the purchase of a full open license being required.

The material box attaches to the 3D printer to pour the powder into it.

Post-Processing and Ecosystem

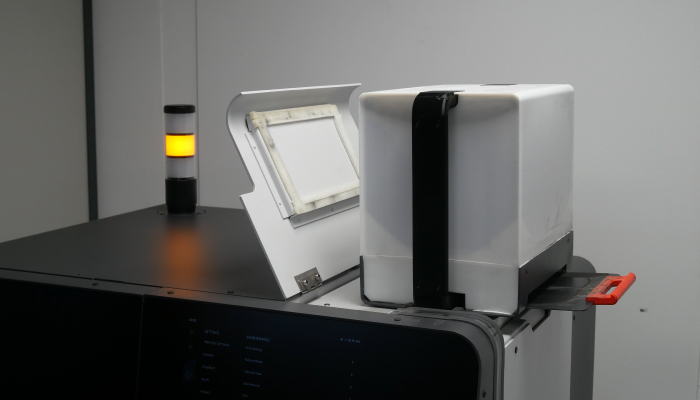

The RMS220 comes with a dedicated cleaning station: the C220-P. Compact and well-designed, it allows for cleaning, sifting, and recycling the powder directly after printing.

It can be used closed, with integrated gloves, or open, by removing the front panel for more direct access. Integrated ventilation captures suspended powder, preventing emissions.

The cleaning station screen allows, among other things, monitoring the temperature of the powder in the build unit, configuring and launching mixing cycles for powder recycling.

The air gun was not yet present in the test version, but it will be included in the final version to accelerate powder removal. Raise3D recommends using one station per material to avoid cross-contamination, a crucial point in SLS.

The air filtration system of the cleaning station allows it to be used “open,” without the front panel.

An automated blast cabinet is also planned for early 2026 to complete the post-processing ecosystem. The manufacturer aims to offer a comprehensive SLS solution, from slicing to the finished part, including powder recovery and recycling.

Conclusion

- Contents of 3D Printer 9.5/10

- Software 9.5/10

- Print Quality 10/10

- Getting Started 9.75/10

Pros:

- 75 W Fiber laser

- Integrated nitrogen generator

- Detachable Build Unit

Cons

- The touchscreen is impractical with gloves

- Automatic nesting could be improved

For its first foray into SLS, Raise3D has made a successful debut.

This first powder-based machine doesn’t just tick the technical boxes: it demonstrates a genuine consideration of the entire workflow, from slicing to post-processing, with a modular and scalable approach. Compact, high-performing, and designed for production, it positions itself as a serious alternative to established market players.

The RMS220 stands out thanks to its combination of a powerful and stable fiber laser, an integrated nitrogen generator (a rarity in this range), and a detachable Build Unit that simplifies continuous production management. Performance observed in PA11 confirms the system’s maturity: the resulting parts are clean, consistent, and exhibit high dimensional accuracy.

The few limitations identified, notably the touchscreen’s unresponsiveness when wearing gloves and the nesting system still being optimized, remain minor compared to the machine’s overall balance. We simply would have liked to see some ergonomic features found on Raise3D’s resin post-processing stations, such as capacitive zones allowing interaction with the machine without direct contact, which would be particularly practical in a powdery environment.

Offered at €26,999 excluding VAT in its standard configuration (printer, Build Unit, cleaning station and 1 year warranty), the RMS220 is clearly aimed at laboratories, design studios and small industrial structures looking to internalize SLS production without investing in a heavy or complex machine.

Beyond the hardware, Raise3D is laying the groundwork for a complete and coherent ecosystem, with ideaMaker software now adapted for SLS and post-processing workstations designed to seamlessly integrate with the workflow. If the final version lives up to the promise of this prototype, the RMS220 could well establish itself as one of the most relevant SLS solutions in its category, combining compactness, performance, and reliability. To learn more about the Raise3D RMS220 and the entire Raise3D ecosystem, visit their official website HERE.