3Dnatives Lab: Testing the Guider 3 Plus 3D Printer From Flashforge

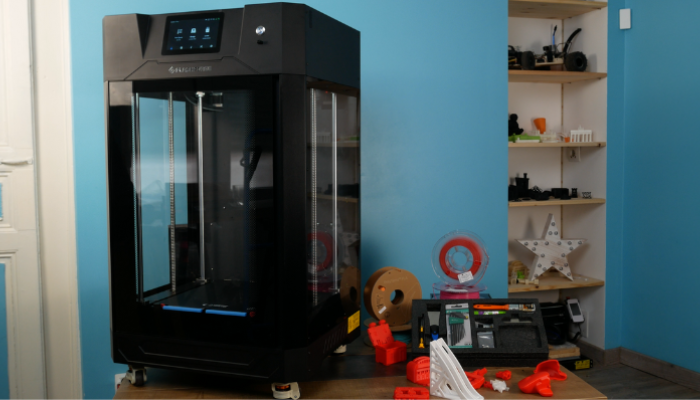

Created in China, in Jinhua, in 2011, Flashforge is a historical player in the desktop FDM/FFF 3D printer market, with many recognized models to its name including the Creator, the Finder and the Dreamer. More recently, the brand has also entered the resin 3D printer market with the Hunter and Foto models. Now with the recent release of the Guider 3 Plus, Flashforge’s latest FDM/FFF 3D printer model, we had the opportunity to receive it in our lab.

Available for a price of about $6,799 including VAT and shipping (€5,500, excluding VAT and shipping), this new machine features a large, fully enclosed printing enclosure and challenges the competition in the professional FDM/FFF 3D printer market, confirming the Flashforge’s efforts to professionalize its range. Below, you can find our test and discover the features and performance of the Guider 3 Plus 3D printer in the 3Dnatives Lab.

Unwrapping the Flashforge Guider 3 Plus

As soon as it arrived, we freed the Flashforge Guider 3 Plus from its box and discovered the attention paid by the Chinese manufacturer to protection during transport. The packaging consists of a thick, rigid cardboard box, while the printer is protected by a plastic film and foam blocks.

Once the box was removed, we take the machine out of the pallet with the help of its integrated wheels. At 635.5 x 590.5 x 1060 mm and 70 kg, it is convenient not to have to lift the machine. Although two people are recommended to set up the machine, the built-in casters make it easy to move the printer.

The Flashforge Guider 3 Plus is a large professional 3D printer

Once set up in our lab, we open the large front door to remove the last of the protective foam and other safety features needed to transport the enclosure inside. Under the printing plate, we discover a cardboard box that turns out to be a foam tool drawer containing a large selection of accessories.

These include two pliers (fine nose and cutting), eight allen/six-sided wrenches, a syringe of thermal paste, tweezers a flat screwdriver, a glue stick, a paintbrush, a thin steel strip (used to adjust the printing height of the first layer), grease (for maintenance of moving parts), a tool to unclog the nozzle in case of filament blockage, and finally, two fuses.

Flashforge provides a large number of accessories useful for the use of the 3D printer

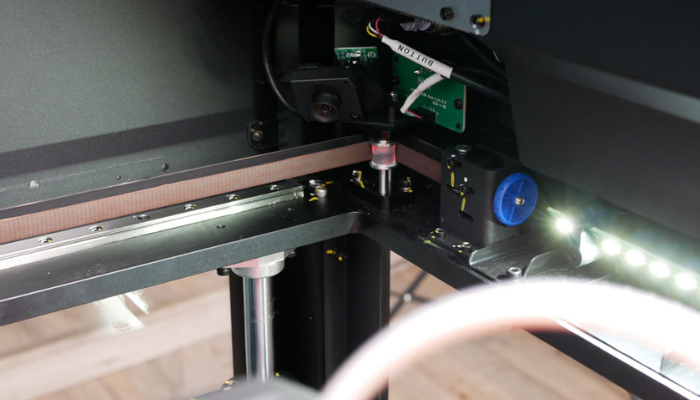

Like the vast majority of professional FDM/FFF machines, the Guider 3 Plus features a sturdy aluminum frame and steel and plastic panels for finishing. Thanks to large windows on the front, top and sides of the 3D printer, the Guider 3 Plus offers great visibility over the printing area of the machine, which is rather generous with its volume of 350 x 350 x 600 mm. Also, to allow the user to always monitor the prints, even from a distance, Flashforge has equipped the Guider 3 Plus with a camera and a strip of LED lights.

Coupled with the LED strip, the camera allows for easy remote monitoring

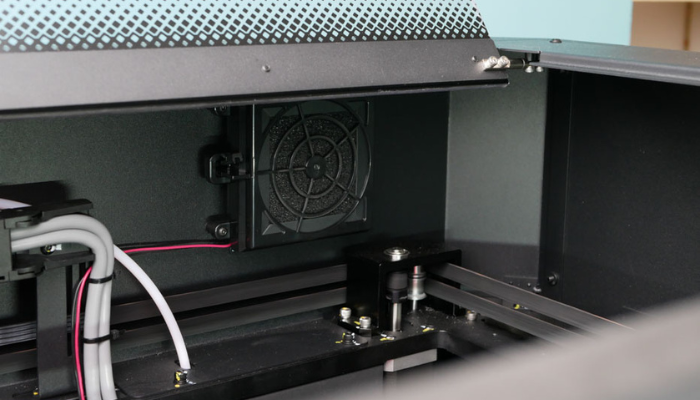

On the front, the Guider 3 Plus is equipped with a 7-inch touch screen, a USB port and a power button while on the back, it has two slots reserved for materials, an RJ45 port (Ethernet), a power port and a power button. Also noticeable is the presence of cutouts for air circulation in the back steel panel (for cooling the motherboard and filtering the air in the enclosure).

The enclosed printing chamber is equipped with a HEPA air filter and activated carbon

To ensure optimal printing whatever the material used, the machine integrates two storage bays for filament spools. These are adapted to most material spools (up to 1 kg of filament). Moreover, they are airtight and include places for 3 bags of silica gel (included in the accessories) as well as a hygrometer to control the humidity level.

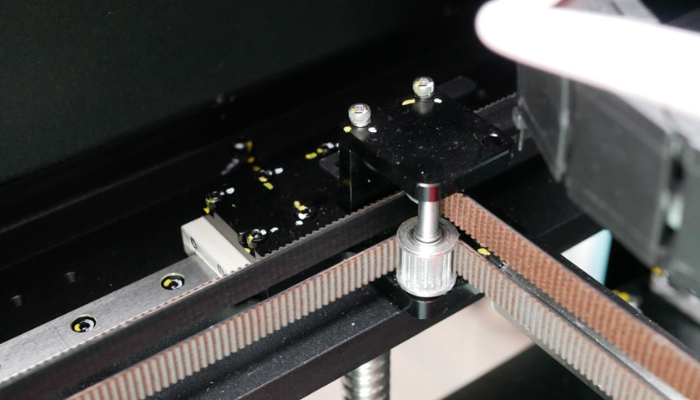

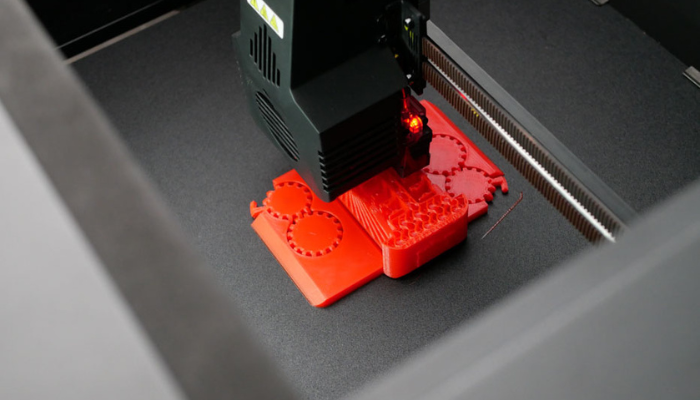

Mechanically, the Guider 3 Plus has only one hotend and to ensure its movement, the Guider 3 Plus relies on a Core XY system driven by two nema 17 motors, and a system of pulleys and belts whose tension is easily adjusted by knurled screws. The X and Y axes roll on linear rails ensuring precision and durability while the Z axis is guided by two worm screws and rests on 4 ball bearings moving on 4 steel rods, located at the ends of the table.

The Core XY motion system is based on reliable and precise components

Installing the 3D printer

Once the machine is in place, it should be noted that no assembly is necessary, the printer is delivered ready to print (once the material is installed of course). To start the Guider 3 Plus, you just have to plug in the printer, connect it to the Ethernet (it will be possible to connect it to a Wi-Fi network in a second time), activate the switch at the back and finally turn on the printer thanks to the button on the front.

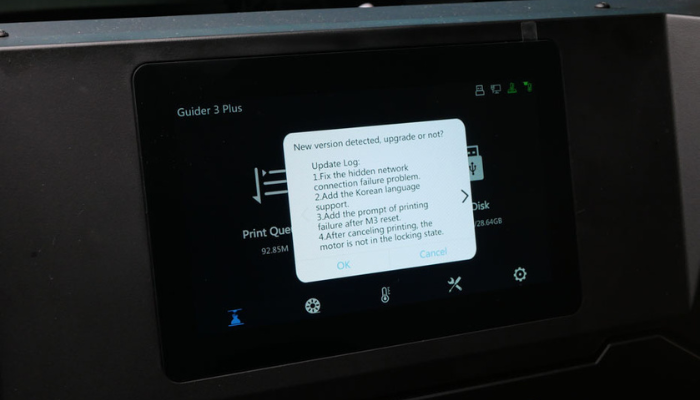

The 7-inch screen welcomes the user with its intuitive interface separated into 5 complete menus: printing, material, temperature, standard settings and advanced settings which include both machine settings and maintenance guides. Note that this interface is available in 7 different languages.

Connected to the internet, the machine updates itself automatically and informs the user via its large touch screen

Before any other operation, it is necessary to go to the material menu to insert a filament. After pressing the loading button, the machine asks to specify the material and heats the print head to the appropriate temperature. Then simply open the filament storage bay at the back of the printer (note that the only one on the left is connected to the extruder via a PTFE tube), place a spool in it, then insert the filament in the PTFE tube before pushing it to the extruder which then takes care of finishing the operation.

Although at this point the printer is already ready to print, it is preferable to level the plate. This procedure consists in placing the thin steel sheet (supplied in the tool “drawer”) between the nozzle and the printing plate and then adjusting the height of the latter. Then, the printer automatically measures the flatness of the plate thanks to a mesh of points taken by an induction sensor. Once this is done, you need to go to a computer to download the slicing software used to prepare the models to be printed for the Flashforge Guider 3 Plus 3D printer.

FlashPrint software & FlashCloud/PolarCloud interfaces

Flashforge has developed its own slicing software for its printers, which is simply called “FlashPrint”. Although Flashforge recommends to use its own proprietary software, the manufacturer gives however the possibility of using other recognized slicers (Cura, slic3r, …), provided that you parameterize yourself the printing profiles or contact the after-sales service to obtain the pre-configured profiles.

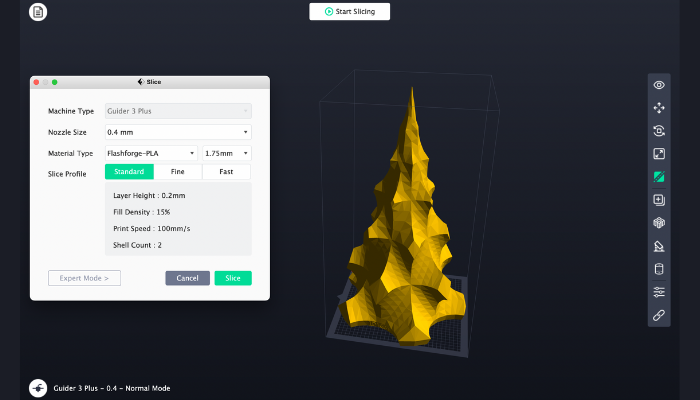

For the test, we used the manufacturer’s software which natively includes profiles adapted to the Guider 3 Plus as well as to a large panel of materials. The application, available on PC, Mac and Linux, is available with 11 languages, and compatible with a large number of file formats, the main ones being 3MF / STL / OBJ.

FlashPrint is the proprietary slicer developed by the Chinese manufacturer

In addition to the standard slicing features, Flashforge also included options for repairing damaged files, duplicating, mesh cutting and automatic part layout in FlashPrint. Once sliced, the software also allows the print file to be sent to the 3D printer over a local Wi-Fi network. It is also possible to observe the prints thanks to the monitoring camera, to take pictures, to control the printing and to turn on the LEDs, all this, still in local network. To enable all these printer management operations to be performed outside the local network, Flashforge offers to connect the machine to its own cloud, FlashCloud or to the Polar3D cloud.

Despite its complete and intuitive interface, we noticed a slight bug on the proprietary slicer, as the whole interface (especially the buttons and icons) is displayed in reduced size when used on a 4K screen. This problem, which we reported to Flashforge, is an error related to the resolution of the screen used, but should logically be corrected in a future version. With all of its built-in features, easy-to-use interface and fast slicing speed, FlashPrint leaves nothing to be desired when compared to other competing applications.

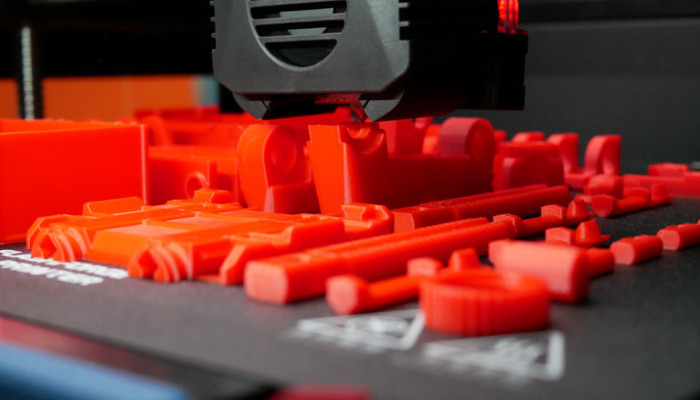

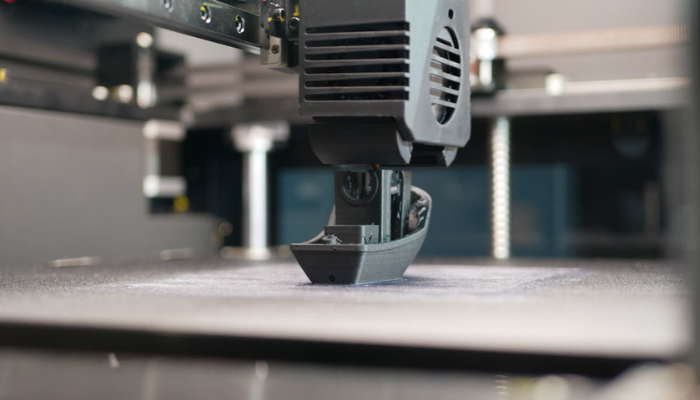

First Prints on the Guider 3 Plus from Flashforge

Once the model was decided, we launched our first print, over Wi-Fi, via the slicer. At first, we used the PLA supplied with the printer. This first part, a “print in place” model representing the functioning of an engine, is faithfully reproduced and all the moving parts went into motion as soon as the crank is turned. With various cantilevered parts and tight tolerances to validate, this print was very promising. The pre-configured profile used is well set up, which offers an almost Plug-&-play experience.

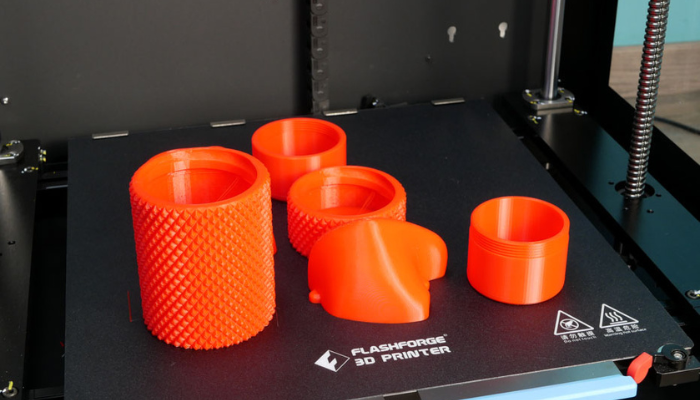

In our other prints, however, we notice that the default presence of the raft on the pre-configured profiles is not useful, thanks to the textured PEI tray providing sufficient adhesion. Thus, we suggest disabling this option in the future to save time and material. Also, the reliability of the machine is reinforced by the use of the induction sensor allowing users to measure a point mesh of the printing plate to correct a possible flatness defect (problem which can cause a lack adhesion issues for the part on the plate).

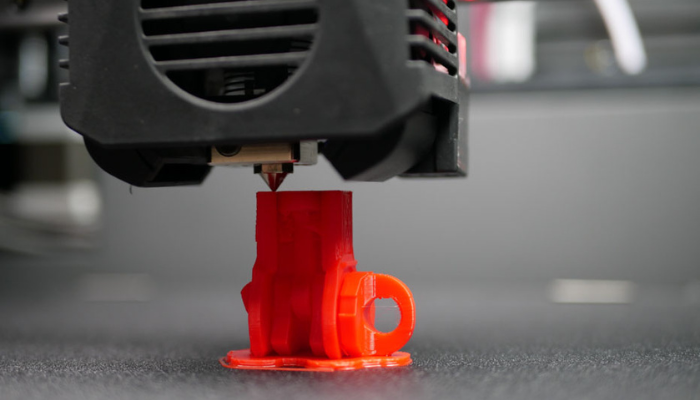

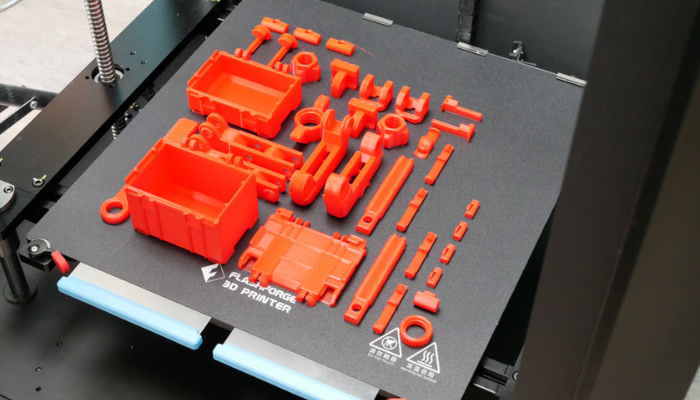

The Flashforge 3D printer is equipped with a hotend capable of reaching an extrusion temperature of 320°C. Coupled with the flexible PEI-coated steel magnetic plate capable of heating up to 120°C, the steel nozzle that comes as standard and the direct drive extruder, the Flashforge Guider 3 Plus is compatible with a wide range of materials from simple PLA to more technical filaments such as PA-CF. This rich compatibility is accompanied by an intuitive and quick filament change process and a second filament storage bay that allows the filament to be conditioned in a low humidity environment. During our test, we had the opportunity to try various materials such as PLA with which we printed most of our models, but also more technical and resistant filaments such as ABS, PETG, PA-CF (carbon fiber filled nylon) and finally, PC.

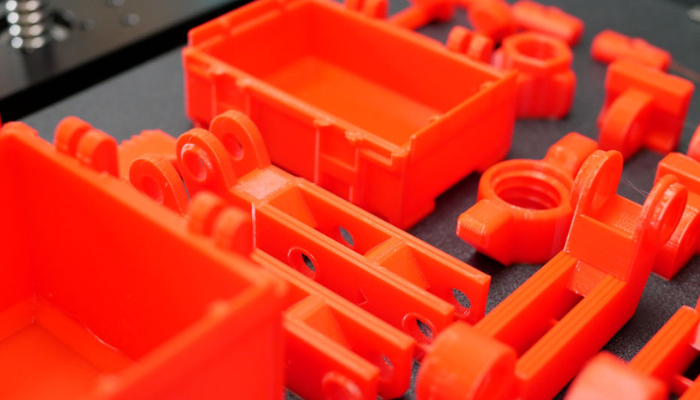

During our printing, the pre-configured profiles allowed us to obtain the desired results without having to readjust the printing parameters. The vase mode and the fast printing (up to 250 mm/s) save production time without degrading the final visual result. Indeed, the motion system and the robust frame of the machine allow it to reach high printing speeds while ensuring precision and reliability. Thus, it is possible to print parts at 250 mm/s, all without noticing ringing or ghosting artifacts (signs of a lack of rigidity and precision during printing).

Thanks to its large flexible printing plate, the Guider 3 Plus is ideal for 3D printing in series

The Guider 3 Plus allows you to quickly print precise parts

The steel nozzle of the Guider 3 Plus allows it to print composite materials such as PA-CF

Conclusion

- 3D Printer Features and Accessories 10/10

- Software 9/10

- Printing Quality 9.5/10

- Ease of Use 9.5/10

Pros:

- Printing volume

- Quality

- Software

Cons:

- One extruder

- Availability

Designed to expand Flashforge’s professional line, the Guider 3 Plus offers a large print volume and good material compatibility, all while ensuring reliability and repeatability thanks to robust components. Its large 7″ touch screen on the front panel provides a complete interface for machine control and maintenance with integrated guides.

Coupled with a powerful print head and flexible plates, the Flashforge Guider 3 Plus’ large enclosed enclosure allows it to handle a wide range of materials. In addition to its machines, Flashforge has also developed its own slicing software that is second to none in the market. Flashprint offers a wide range of features and ensures fast slicing.

For the price of $6,799 (including VAT and shipping)/5500€ (excluding VAT), the Guider 3 Plus is really competitive even if the only point we do think is unfortunate is that it has only one extruder. A second extruder would have been welcome to offer bi-material printing or why not a duplication mode via an IDEX system, a feature that is gradually becoming the standard on the market. It will be interesting to follow Flashforge’s future progress on this subject.

In conclusion, the Guider 3 Plus is a machine that will easily fit into a professional environment to produce large parts in a wide variety of materials. If would like to learn more about Flashforge and its 3D printer ranges, as well as to request free samples, you can visit their website HERE.

In the past they would tell you to use their slicer and wouldnt even attempt to use anything else, but now if you ask they will explain to you how to use cura. They have posts everywhere explaining how to use it so they know that it’s a problem, or at least they realize that having the software be entirely specific to them is not something that people who are interested in 3D printers are interested in buying into.

Free software like blender is just so good that there’s no reason for all these companies to try to hold on to their proprietary stuff. It’s already as good as zbrush, it can do pretty much everything that sculpting programs do, it just needs better parameterization.