3Dnatives Lab: Testing Hey Gears Ultracraft Reflex RS 3D Printer

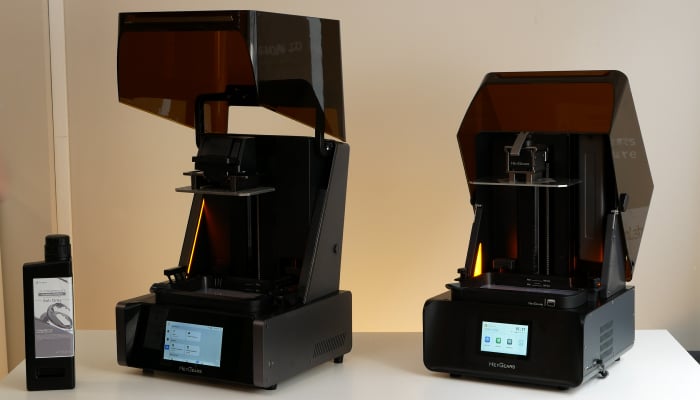

HeyGears, renowned for its professional dental 3D printing solutions, has recently made a splash on the consumer market with its first resin desktop printer, the Reflex. Following the success of the UltraCraft Reflex, the Chinese brand now offers a more affordable model: the UltraCraft Reflex RS. Designed to meet the expectations of users looking for a more economical solution, the UltraCraft Reflex RS (Rapid Shaper) promises similar print quality to its predecessor, but at a lower price. In this review, we take a closer look at this new machine, its specifications, performance and the compromises made to reduce its price.

While the classic Reflex was aimed at a wider audience with a complete ecosystem, the Reflex RS is positioned as a more accessible option while promising improved performance, notably thanks to an 8K resolution on its LCD masking screen. At first glance, it seems to offer an interesting medium between print quality and competitive price, but what compromises has the manufacturer had to make to reduce the price of the desktop resin 3D printer? In this article, we’ll take you back to our detailed test of the HeyGears Reflex RS to see if it lives up to its promise.

Unpacking the UltraCraft Reflex RS

The Reflex RS accessory pack is simpler than that of the Reflex. Unlike its predecessor, the Reflex RS comes with a silicone spatula, two allen keys, a metal spatula and a starter guide. The Reflex, on the other hand, offered a more complete set of accessories (cleaning trays, resin filters, cutting pliers), making it easier to use. The absence of these tools on the RS means that users will have to equip themselves, potentially increasing the total cost.

With dimensions of 380 x 360 x 584 mm, the Reflex RS is slightly more compact than the Reflex, while offering greater print volume (222 x 122 x 230 mm vs. 192 x 121 x 220 mm). To optimize this space, HeyGears has moved the power supply to the outside of the printer, thus requiring additional space for this external unit.

Reflex RS follows the aesthetic lines established by Reflex

In terms of design, the Reflex RS retains the brand’s distinct aesthetic, but its construction elements are less robust than those of the Reflex. The chassis incorporates more plastic, particularly in the hinge mountings, which could potentially affect its long-term durability. In addition, there are gaps in the frame that could let in dust, a shortcoming absent on the original version. The control screen is also smaller, five inches diagonally versus seven on the Reflex. The various connectors, apart from those reserved for the PRM, have been moved to the right-hand side of the machine.

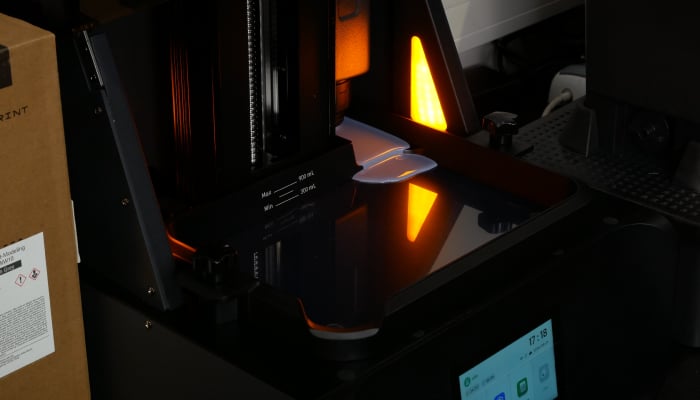

One of the most notable compromises concerns the platform mounting system. Unlike the Reflex, which included a tilting mechanism to drain the resin, the Reflex RS has done away with this function. You’ll need to print an adapter to remove excess material from your prints, which can add an extra step to the process.

On the Reflex RS, HeyGears has simplified the tray attachment system, making it necessary to print an adapter to tilt the tray

Additionally, the printing plate on the Reflex RS is solid, unlike the perforated one on the Reflex, a choice that can have practical consequences. The solid plate is flat on top, therefore tending to retain the resin, requiring greater care when removing the plate from the machine. If you’re not careful, the resin can spill onto the printer or worktop, increasing the risk of mess.

3D Printer Installation

Installation of the Reflex RS follows the same simplified process as the Reflex, with assistance via the 5” touch screen. Although smaller than that of the Reflex, this screen offers a fluid interface, aided by a firmware update also available on the standard Reflex. This system includes a virtual spirit level, making it easy to level the machine thanks to the adjustable feet, as well as automatic material detection via NFC tags on the resin cartridges.

The reflex RS uses an automatic gravity flow system to ensure a sufficient resin level during printing

Once the printer has been plugged in and started up, the screen guides you through each step of the installation, from automatic buildplate calibration to Wi-Fi connection. The machine is ready to print in no time.

An interesting new feature is the gravity-fed resin system, which is simpler and less costly to maintain than that of the Reflex. It also reduces the risk of breakdowns.

The UltraCraft Reflex RS uses a 405 nm light source, compared with 385 nm for the Reflex. This longer wavelength enables deeper curing and speeds up the printing process, although it may slightly affect accuracy. This choice is aimed at a wider audience, prioritizing speed and accessibility over extreme precision. Indeed, 405 nm is more compatible with less technical and more affordable materials.

HeyGears Reflex RS uses proprietary resin cartridges

However, the Reflex RS does not have an integrated heater module. If you’re working in a low-temperature environment, it’s advisable to invest in the PRM (Pulsing Release Module) kit, sold separately for around $199. This module stabilizes the resin temperature, guaranteeing consistent prints even in variable climatic conditions. Despite this addition, the Reflex RS is still around $200 less than the Reflex.

Software and Ecosystem

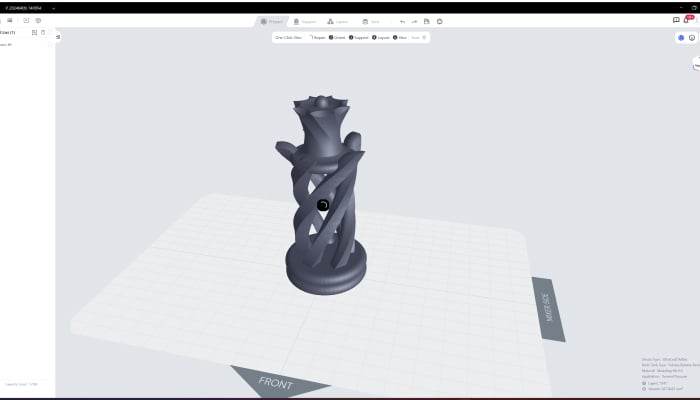

Like the Reflex, the Reflex RS integrates seamlessly into HeyGears’ Blueprint ecosystem. This connected software enables remote monitoring and control of the entire printing process, whether via the mobile app or the desktop software. Users can manage print and post-processing jobs directly from the platform, simplifying workflow. Although there have been no major updates since our Reflex test, the interface remains intuitive, with advanced features such as one-click slicing, which simplifies print preparation.

The BlueprintGo mobile application is particularly useful for keeping track of the various printing and post-processing stages

Nevertheless, as noted in our Reflex review, Blueprint Studio still lacks some of the advanced features found in other slicers. The absence of the increasingly common 3MF format may limit certain uses.

Blueprint Studio’s strong point is undoubtedly its integration with the HeyGears ecosystem. Thanks to cloud connectivity, files can be sent directly to the printer and post-processing machines, automating certain settings according to the material or model to be printed. However, if you’re looking for more flexibility, particularly in terms of third-party materials or formats, this closed approach could represent a limitation.

Blueprint, HeyGears’ proprietary slicer for preparing models for printing and sending them to machines in the wireless ecosystem

While this ecosystem is already well thought-out, one feature we’d like to see more of is the integration of global commands to launch both printing and post-processing, without having to manage them separately. HeyGears could thus enable post-processing tasks to be sent directly from the mobile app, which could make the user experience even smoother.

Print Performance

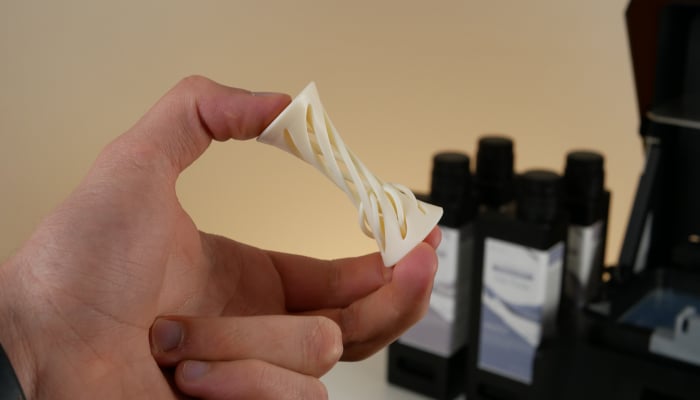

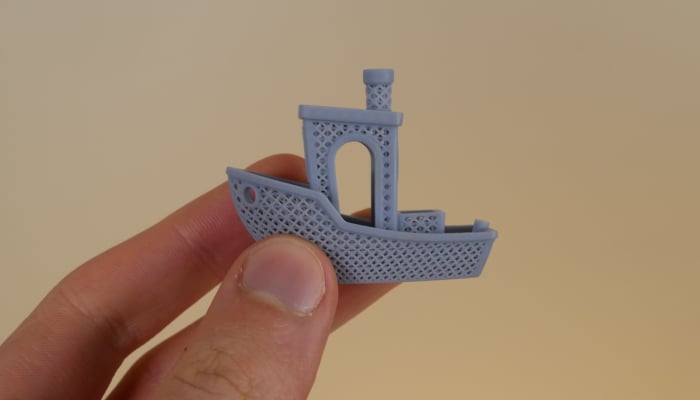

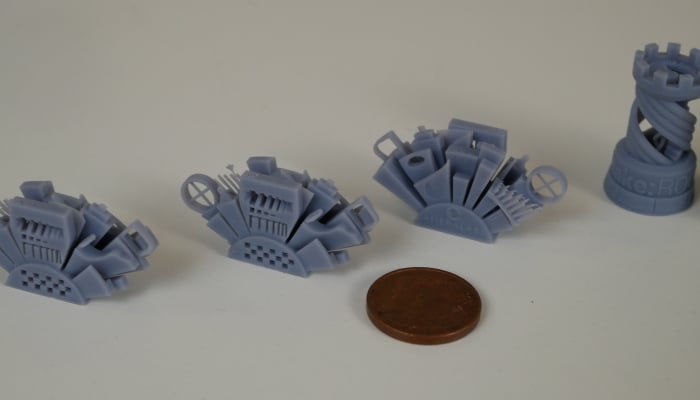

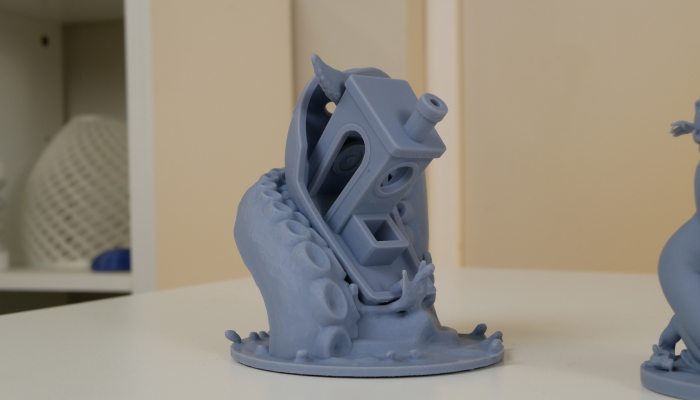

In terms of print quality, the Reflex RS lives up to the expectations of a high-end resin 3D printer. Prints are crisp and precise, with virtually invisible layers, delivering strong, durable parts. The difference in quality between Reflex and Reflex RS prints is barely perceptible to the naked eye. The RS benefits from a slight increase in speed thanks to a more optimized algorithm, according to the manufacturer, and the 405 nm light source, compared with 385 nm for the Reflex, enables faster curing.

However, there are a few practical compromises. Unlike the Reflex, the Reflex RS does not have a weight sensor to measure resin levels. This can be a problem for longer or larger prints, where it’s difficult to predict how much resin is left.

Another notable point with the Reflex RS is the expansion of the proprietary resin portfolio. HeyGears has introduced cheaper materials to make its ecosystem more affordable and attractive to users accustomed to open hardware solutions. The range now includes resins for a variety of uses, from technical parts to rapid prototyping applications. However, as with the classic Reflex, having to use HeyGears materials exclusively can be a drawback if you’re looking for more diversity in your choice of materials.

Unfortunately, the wash bins are too small for the Reflex RS tray to fit into

Regarding materials, the Reflex RS is not compatible with all the manufacturer’s resins due to different wavelengths. However, it does support several mainstream resins, such as water-washable resins, wear-resistant resins and entry-level materials.

Supports on prints with the Reflex RS are generally easy to remove, although some tougher materials, such as PAWR10 resin, require more effort. Post-processing is slightly less convenient than on the Reflex. The shared washing station is not large enough to hold the RS platform, so parts have to be removed before cleaning.

One of the points we raised when testing the Reflex was the high noise level, due in particular to the PRM and post-polymerization station. With the Reflex RS, these accessories remain unchanged, but the noise level can still be annoying in an office environment.

Conclusion

- 3D Printer Features and Accessories 8.5/10

- Software 9.5/10

- Printing Quality 10/10

- Ease of Use 9.5/10

Pros:

- Attractive price

- High print quality

- Connected ecosystem

Cons:

- No resin level sensor

- Heating module sold separately

- Tray attachment system and flat tray (increased risk of mess)

The UltraCraft Reflex RS is positioned as a more economical alternative to the Reflex while maintaining high print quality. It offers greater print volume, and slightly enhanced performance in terms of speed. However, these improvements come at the price of a few sacrifices, such as the absence of a resin level sensor, the removal of the integrated heating module, and reduced compatibility with more technical materials.

Available from $999, the Reflex RS is an excellent choice for users wishing to get started or perfect their skills in desktop resin 3D printing at a reasonable price. However, for those looking for a more complete solution or using technical materials, the Reflex remains a good option to consider.

The Reflex RS is aimed above all at users seeking a high-performance, easy-to-use printer at a more affordable price while accepting the compromises associated with a closed ecosystem and proprietary materials. So, for those wishing to explore the possibilities of a reliable resin printer with advanced features, but on a tighter budget, the Reflex RS is a serious option to consider. To find out more about the HeyGears Reflex RS, its ecosystem and materials, visit the manufacturer’s website.