3Dnatives Lab: Testing BCN3D’s Epsilon W50 3D Printer

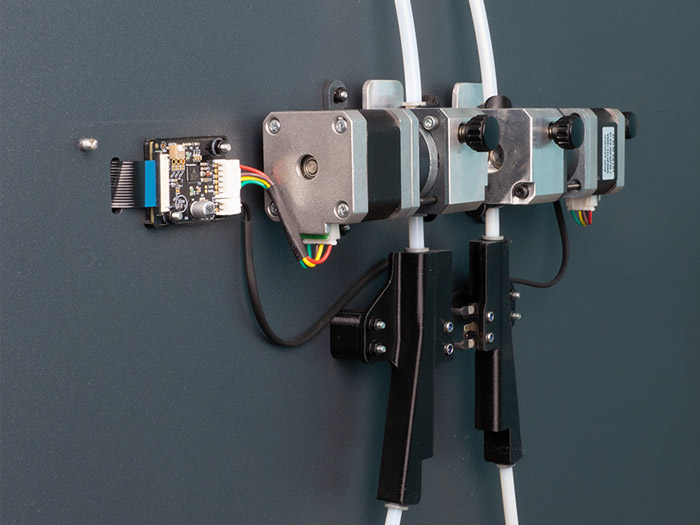

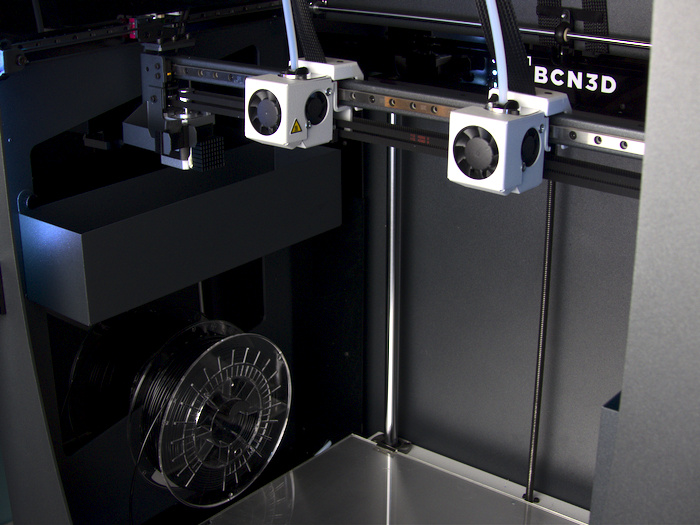

Barcelona-based manufacturer BCN3D has become a major player in the field of 3D printing in recent years, known in particular for having developed IDEX (“Independent Dual Extruder”) technology, which combines two independent extruders within a single 3D printer, with the possibility of printing in several materials and using manufacturing modes such as Mirror or Duplication for the production of parts simultaneously. More recently, the brand unveiled its new line of Epsilon machines, which are more focused on industrial users. Consisting of the W27 and W50 models, this series offers the standards of the most advanced FDM machines, namely a touch screen, a HEPA filtration system, Hiwin linear rails, a Dual Drive extrusion system from Bondtech™, a hotend specially developed by E3D, an enclosed enclosure along with a heating plate reaching 100°C and a maximum extrusion temperature of 300°C. The difference between the two machines, as their names suggest, comes from the build volume, namely 27L vs. 50L.

So what are the features of this new range? What level of quality can we expect? Who is this machine intended for? With ambitious performance figures and a price tag of $7,995 from BCN3D’s American resellers (€6,995 in Europe), the W50 seems to be a serious contender in the race for professional FDM 3D printers. 3Dnatives had the pleasure to receive the W50 for a test.Without further ado, check out our in-depth review of the Epsilon W50! You can also watch our video of the review below.

1. Unpacking the Epsilon W50 from BCN3D

As the machine arrives on a pallet, the impressive dimensions of the Epsilon W50 are quickly evident. With a weight of 37 kg (81.8lbs) and dimensions of 27.2″ x 20.9″ x 35.4″ (690x530x900 mm), it is clearly no longer a simple desktop 3D printer. Please note that unpacking it can be a little complicated if you do it alone.

In addition to the 3D printer, all the tools and accessories necessary for the proper functioning of the machine were also included. This includes spatula, needle-nose pliers, Magigoo™, a set of allen wrenches, an SD card, a power cable, hotend shims, a leveling shim and all the necessary documents (warranty and startup guide). Once this has all been unpacked, the glass printing plate can be taken out, revealing its large dimensions, 16.5″ x 11.8″ x 15.7″ (420x300x400 mm). The 3D printer is then released from its XXL packaging (which must be kept in case of return during the 2-year warranty period).

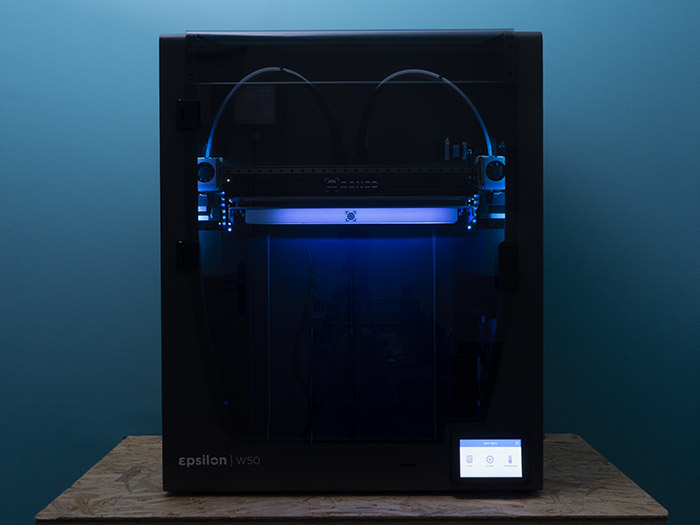

Visually, its steel and black acrylic frame makes the W50 a modern and elegant machine while suggesting solidity and reliability. On the lower right front panel, there is a 5″ full-color touch screen; next to it is the slot for the SD card used to transfer 3D models. On the back of the 3D printer, there is the power socket as well as an Ethernet port, a USB-A slot for the Wi-Fi adapter supplied with the machine and a USB-B slot for connecting a computer if needed. The top cover of the machine and the door are made of transparent acrylic, slightly smoked, which makes the printing process visible even with the door closed. There are also blue LED strips that light up the inside of the machine, making the printing process all the more visual.

The imposing Epsilon W50

The BCN3D Epsilon W50 is delivered with its set of tools and accessories

The Dual Drive extrusion system from Bondtech™

2. Installation of the W50 3D Printer

Once unpacked, we started to set up the W50 3D printer, which took less than twenty minutes. To begin, you’ll need to install the glass printing plate as described in the Quick Start Guide, then turn on the printer and simply follow the instructions on the touch screen (the instructions are available in English, French, German, Italian, Portuguese, Spanish and Mandarin).

The Quick Start Guide includes several QR codes to make it easier to get started. QR codes that were well recognized by the smartphone Huawei P30 Pro we used but not by the Xiaomi mi9T (probably because of QR codes’ size and quality). You can however find all the guides in the support section of the manufacturer’s website HERE. Note that the digital guides are also available in several languages including English.

The 3D printer’s menu guides the user through the setup process, starting with the assisted leveling of the plate, but also adjusting the height of the two print heads for the first layer and adjusting the offset between the two heads on the X and Y axes. These steps are intuitive and well guided overall.

Once these settings are done, the machine proposes the installation of a number of “e-shims” on one of the print heads. A link was displayed on the screen to guide us during this installation but unfortunately, it did not redirect to the active page and the package containing the “e-shims” was not labeled. Unfamiliar with the term “e-shim”, we did a quick search on the internet. We found the web page on BCN3D’s website with instructions and discovered that these “e-shims” were nothing other than the thin aluminum shims provided with the machine. Note that BCN3D is, to our knowledge, the only manufacturer to use this kind of part. Concretely, these metal shims allow users to raise one of the two hotends so that they are both at the same height, which makes the printing process more precise when both hotends are used.

Focusing on the 5″ full-color touch screen of the Epsilon W50

The next step was to configure the Wi-Fi on the machine, except that it did not detect any network. After reporting this problem to BCN3D’s support department, they told us that it was a problem related to the printer’s firmware version. After a quick update via Ethernet, the Wi-Fi was indeed functional.

Although it would have been ideal for BCN3D to tell the user to connect the machine to Ethernet during the first startup (in order to ensure the correct version of the firmware and to avoid the problems of invalid links or Wi-Fi problems), the process of installation and preparation of the machine is relatively straightforward as you can see, with clear instructions via either the control screen or on the manufacturer’s website. Once all these operations are completed, you will have to download the BCN3D slicer to prepare the file and launch the first 3D prints!

Metal wedges, called “e-shims”, raise the print head by a few tenths of a millimeter

W50 integrates’s printing chamber has 2 coils on both sides of the plate. We also see the two independent extruders of the machine

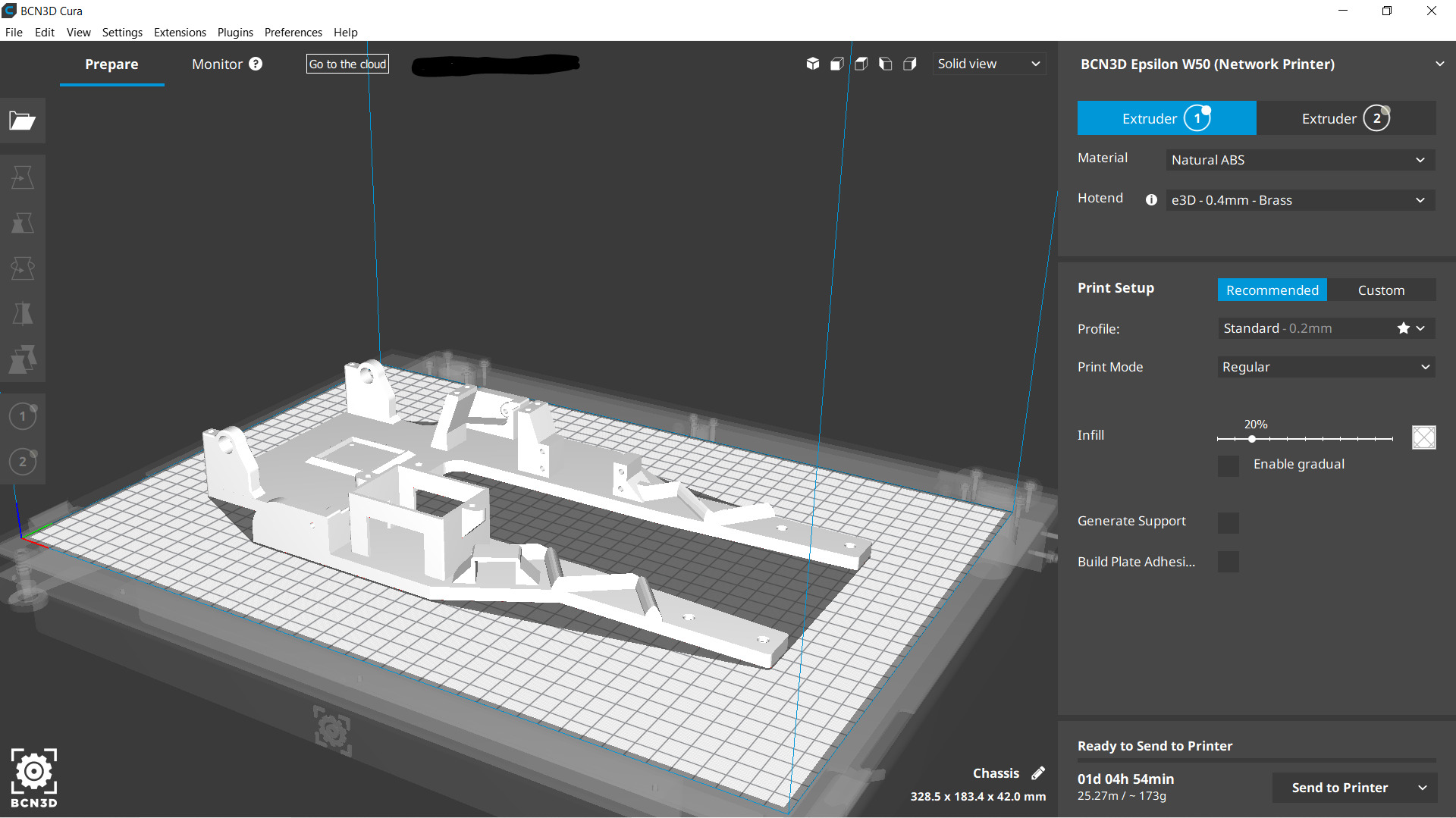

3. BCN3D Cura and BCN3D Cloud software

As for the software, like for all its 3D printers, the manufacturer has opted for a customized version of Cura, one of the most famous slicers on the market. This version proposed by BCN3D is simply named BCN3D Cura and is based, to date, on Cura 3.4.1 (note that the latest version of Cura is 4.8). The slicer uses the same architecture and features already available in Cura and embeds tools specific to BCN3D and its IDEX system (Mirror mode, Duplication and selection of the extruder for the supports).

The Mirror and Duplication options will allow the printing plate to be divided into two equal parts and to reproduce by symmetry or duplicate on the right side of the plate the part present on the left side. These functionalities make it possible to divide production times in half. We already had the opportunity to play with these modes during the test of the Sigmax R19 3D printer from BCN3D.

BCN3D also offers a remote connection solution, the BCN3D Cloud, which allows you to control and launch your prints via the Internet. On BCN3D Cura, a “connect” button is available on the top of the software interface, and allows you to enter your BCN3D Cloud ID to connect the 3D printer directly to the slicer via Wi-Fi. This way, it is possible to send the Gcode to the printer remotely as soon as the 3D model is sliced. Among other features offered by BCN3D Cloud (but absent on BCN3D Cura), it is be possible to monitor temperatures or the status of the 3D printer live.

The interface of the slicer BCN3D Cura specially developed by the manufacturer

4. First 3D prints with the W50

The characteristics of the Epsilon W50 allow it to print a variety of thermoplastics, such as PLA and ABS, as well as more or less technical materials such as nylon, polypropylene, PETG, TPU, PVA, BVOH and composite filaments. Although it is compatible with filaments from other manufacturers, BCN3D recommends using its own materials for better quality prints. By default, the W50 3D printer can accommodate two 500g spools directly in the print chamber on either side of the plates. However, if the user wishes to use larger spools, whose dimensions exceed the dedicated slots, it will be necessary to print spool holders, the model of which is supplied by BCN3D, and to fix them to the back of the machine on the slots provided for this purpose. Also of note, with its new Epsilon line, BCN3D has unveiled the Smart Cabinet, a filament storage system that controls the moisture content of the material. This solution also includes an uninterruptible power supply system that will allow the 3D printer to continue printing even in the event of a power failure.

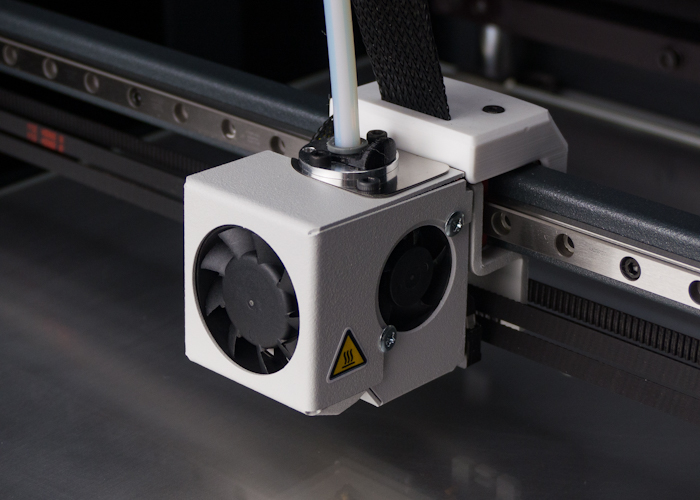

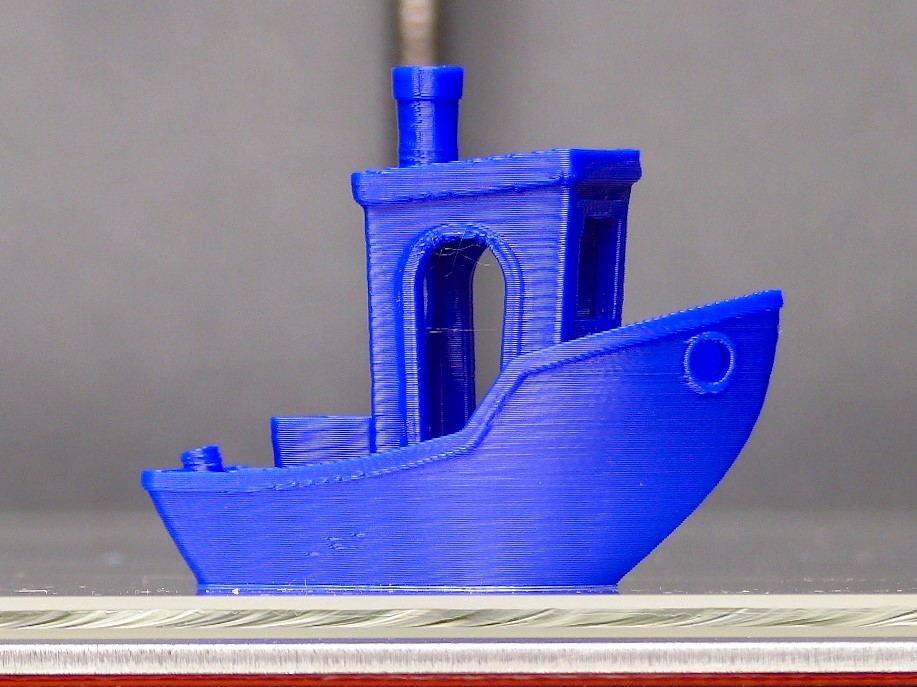

For our first print, we decided to test the Duplication feature to see how easy it is to use. So we printed two Benchies in PLA. This mode, which uses the 3D printer’s independent dual extruders, reduces the production time by half. For example, we were able to print two benchies in the same amount of time that normally making one benchy would take. As for the result, the W50 responded without any problem to the task, with the result being two nice models. The details were faithfully reproduced, no shifts or signs of shaking to be pointed out, even if the 3D printer seems to struggle slightly on the overhangs (unsupported parts of the model). Indeed, as the Epsilon W50 is completely closed, the temperature in the enclosure rises quickly to around 40°C, which slows down the PLA cooling. Moreover, the filament cooling fan blows only on one side of the nozzle, which does not seem to be optimal for cooling the filament.

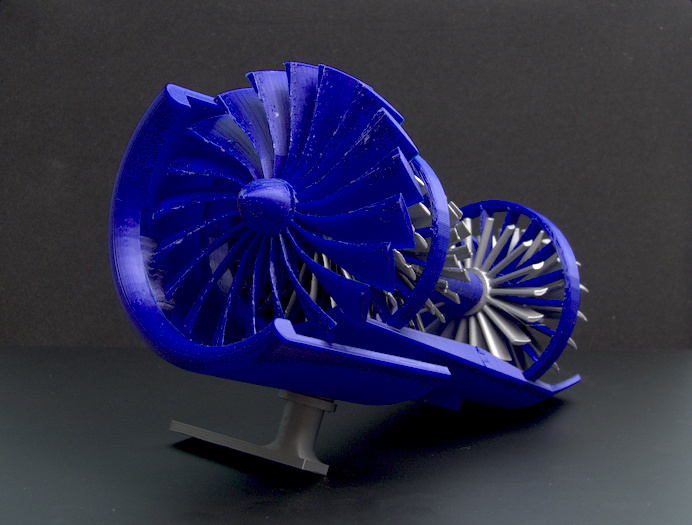

We then went on to test the dual-color print, which also went off without a hitch. We got an almost perfect result for the famous dragon from Park Güell in Barcelona. After some more PLA testing, we tried out some more technical filaments and were pleasantly surprised by the performance of the W50. We tried polypropylene and ABS models with very good visual results. We had no problems with warping or layer separations, both of which can usually occur on this kind of material without fine tuning of the slicer and the machine.

A 3D benchy from Creative Tools printed on the Epsilon W50

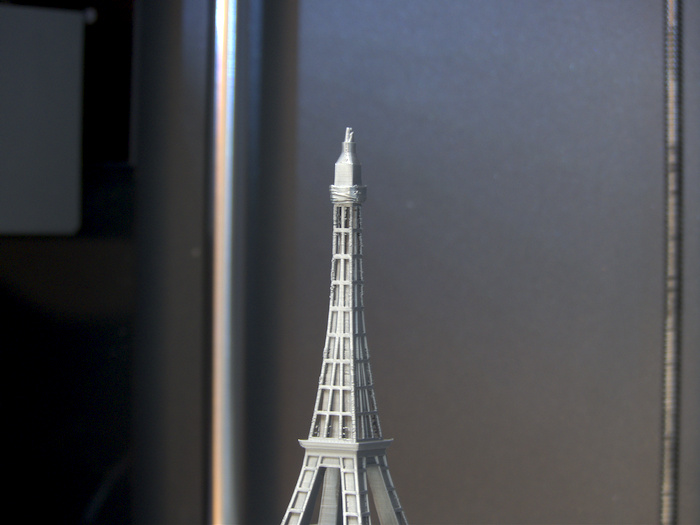

The print head fan struggles to cool the PLA sufficiently, which results in poorer quality on the fine details of this Eiffel Tower, modeled by MiniWorld3D

Bicolor PLA Park Güell Dragon, dual draudy by BCN3D

Aircraft engine in PLA by Jack Imakr

Parts for water rockets and water rocket launchers in polypropylene by US Water Rockets et Racketfued Rockets

Water rocket launcher by Racketfued Rockets printed in polypropylene

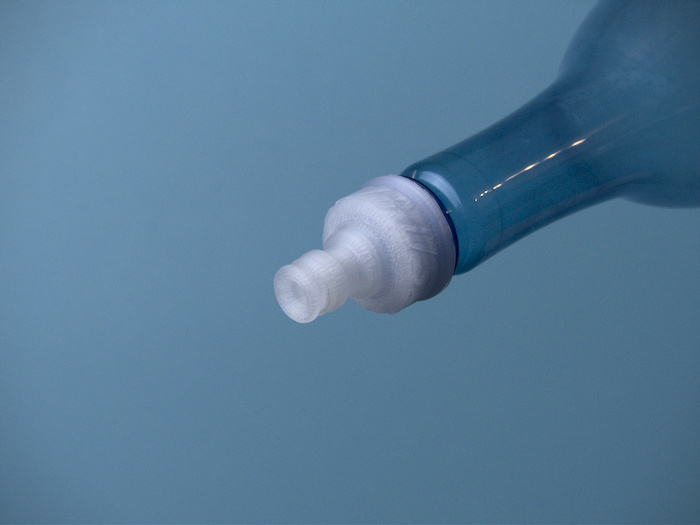

The water rocket nozzle, modeled by US Water Rockets, is screwed on the bottle thanks to a thread that is faithfully recreated during the printing process

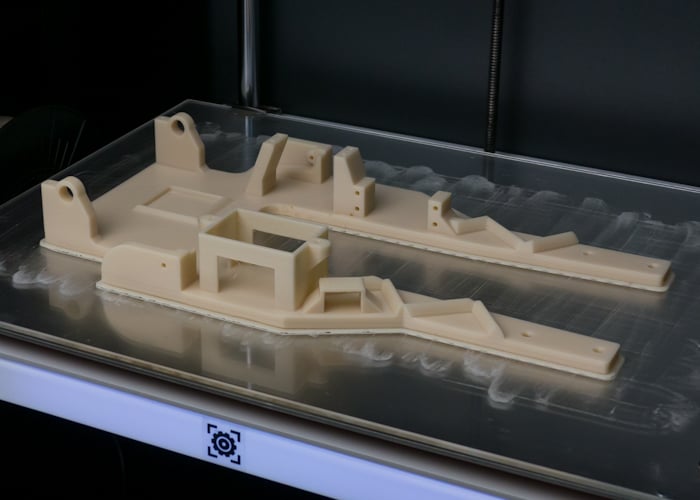

Model car chassis in ABS by Elliot Projets

You Can Find all the 3Dnatives Lab Tests Here

Conclusion

- 3D Printer Contents 9.5/10

- Software 9/10

- 3D Printing Quality 9/10

- Ease of Use 9.5/10

Pros :

– Reliability/Repeatability

– Easy printing of technical materials

– Dual independent extruders

– Printing volume

Cons :

– Price

– Filament cooling system

– Slicer moderately customized for the machine

After more than 180 hours of 3D printing with basic and more technical materials, reliability and repeatability are the two words that sum up the W50. Whether it is the custom material profiles developed by BCN3D, avoiding spending time in the settings of the slicer, or also the hotend capable of reaching an extrusion temperature of 300°C (despite the use of a bowden system) associated with a large heating plate and IDEX technology, the W50 3D printer includes everything that can be expected of a machine of this level. Without revolutionizing the latest models from BCN3D, it is still a successful entry by the Spanish manufacturer into the niche of professional FDM 3D printers.

Among the points to improve, we would have liked a version of Cura even more customized even if BCN3D Cloud offers a nice alternative. We also thought that the cooling system for the filament coming out of the nozzle should be optimized to increase the quality of PLA prints, in our opinion. The price of $7,995 without tax (€6,995) will obviously remain a hurdle for many potential users, but that might be the price to pay for a FDM machine clearly oriented towards production. To learn more about the Epsilon W50 3D printer, visit the BCN3D Technologies website HERE.

Stay away from this printer !

These machines have as many critical firmware bugs as possible. Extruder collison with printing surface elements or with each other are often.

No implemented any failfafe, no safety switch ! Software stop unresponsible. This is crap