3Dnatives Lab: Testing the Sigma D25 3D Printer from BCN3D

Founded in 2012 by three students from the Polytechnic University of Catalonia (also known as BarcelonaTech), the manufacturer BCN3D has become one of the key players in the FDM 3D printing market over the years. Though initially focused on kit machines, since 2018, BCN3D has professionalized to offer professional Plug&play models, such as the Sigma D25 3D printer from the company. These are notable in particular due to BCN3D’s IDEX technology and for their various manufacturing modes such as Mirror or Duplication for the production of parts simultaneously.

The latest generation of BCN3D machines is divided into two series. On one hand, the Sigma D range covers “Desktop” 3D printers ” and is presented as the manufacturer’s entry range. On the other, the Epsilon W range includes the printers known as ” Workstation ” and has been designed more for production. Logically, the names of the printers are composed of the initial corresponding to the name of the range of the machine followed by the volume of printing available in liters. BCN3D thus offers the Epsilon W27, the Epsilon W50 and the Sigma D25.

Following the test of the W50 a bit ago, we had the pleasure to receive the BCN3D Sigma D25 in the 3Dnatives Lab. As mentioned, the Sigma D25 is a desktop printer with a printing volume of 25 liters. It features, among other things, a 5-inch full-color touch screen, Hiwin linear rails, a Dual Drive extrusion system from Bondtech™, two hotends specially developed by E3D (with a maximum printing temperature of 300 °C) as well as a heated print tray (allowing a maximum temperature of 80 °C).

With a price of €3,495 without tax ($3,995.00), who is the D25 intended for? What types of parts can be made? How does the 3D printer differ from other models of the brand? Read our full review of the Sigma D25 3D printer and check out the video of the process below.

Unpacking the BCN3D Sigma D25

For delivery, the Sigma D25 arrives in a box installed on a pallet, a sign that the 3D printer is relatively imposing. When unpacking the machine, it is firmly protected by foam to ensure smooth transport, and indeed its generous dimensions of 690*530*550mm (~27″*20.9″*21.7″) are clear straight away, with total weight of 30kg (~66lbs) to match. Given its volume, it is better to take the printer out with two people.

Also discovered during the unpacking are two rolls of 500g PLA, a 420*300mm (~16.5″*11.8″) glass print tray, as well as various accessories including a spatula, needle nose pliers, Magigoo™ adhesive, a set of three hex wrenches, an SD card, a power cable, hotend shims, a leveling shim, and all the necessary paperwork (warranty and getting started guide).

From an aesthetic point of view, the design of the Sigma D25 is clearly inspired by the manufacturer’s previous generation of 3D printers with a similar aluminum frame, although this one is in an off-white color, offering a resolutely open architecture on the manufacturing platform.

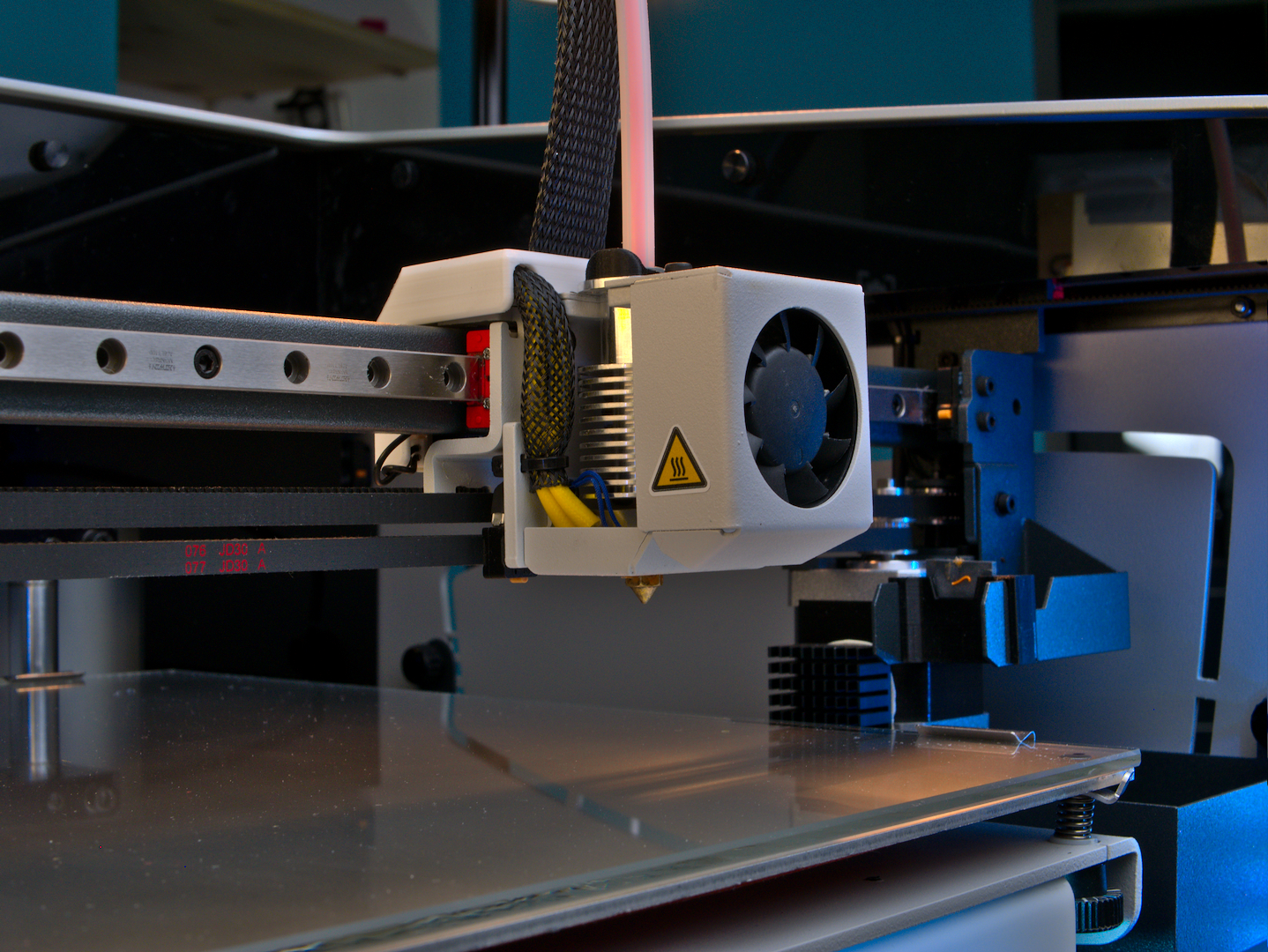

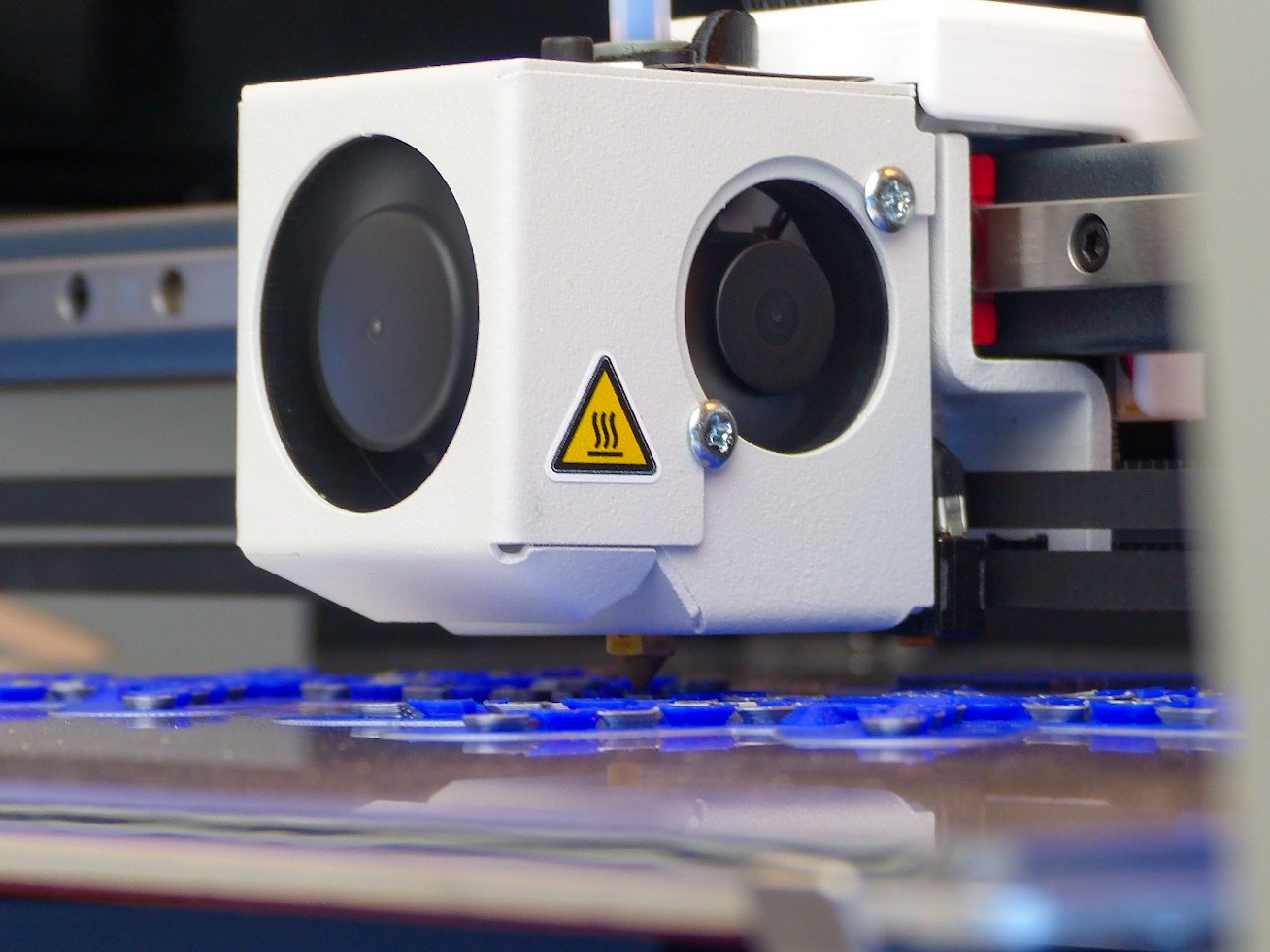

The D25 is solidly built with quality components like this E3D print head moving on Hiwin linear rails

BCN3D has indeed decided to abandon the square format of the Sigma R19 in favor of the rectangular format of its larger sibling, the Sigmax R19. The D25 is thus wider than tall since its printing volume is 420 (Width)*300 (length)*200 mm (Height) (16.5*11.8*7.9 in). This layout is rather unusual since most FDM printers have a larger Z axis (height). This choice was deliberately made by BCN3D as it allows the printing of long parts with a low height, such as an RC car chassis.

In the absence of a closed build chamber, and with a maximum temperature of 300°C (572°F) for the extrusion and 80°C (176°F) for the plate, the Sigma D25 is clearly intended for the printing of standard materials like PLA, PETG, TPU, PVA, BVOH, rather than technical polymers. Although the Sigma D25 is directly compatible with any third party 2.85 mm filament, BCN3D recommends using its own filaments for optimal results. The machine includes two slots for 500 spools on each side of the plate, but if larger spools are desired, the outer spool holders on the back of the printer should be used.

The interface on the 5″ touch screen allows you to start printing, calibrate and maintain the printer

Installing the Sigma D25 3D printer

As the printer arrives pre-assembled, all that remains to be done is to install the glass plate, clip the two bowden tubes that connect the remote extruders to their respective printheads and load a new spool for each extruder. We then proceed to turn on the machine which guides us step by step thanks to its full-color touch screen, in the configuration of the printer. This takes a little under 20 minutes in total.

During start-up, the machine invites the user to connect it to an Internet network (wired or Wi-Fi), and then to connect to a BCN3D Cloud account. It is therefore preferable to have access to the Internet so as to be able to create an account allowing the printer to be identified in the cloud. Internet access is also useful to ensure that the machine is equipped with the latest update.

After these two steps, the machine proposes to launch its initialization process which calibrates the two extruders by adjusting their height relative to the plate as well as their alignment.

The Sigma D25 is equipped with two independent extruders (IDEX)

The setup process is simple as the machine does most of the work itself using its multiple sensors. Manual adjustments are easy to make and the printer’s screen provides additional help by displaying detailed images and animations. Once all the steps are completed, an animation informs you of the success of the calibration process. All that remains is to download the BCN3D slicer to prepare the first print.

BCN3D’s Stratos and BCN3D Cloud software

Regarding the operating system of the printer, as for all its other printers, BCN3D has opted for the Open-Source option by using Marlin. This choice of operating system allows BCN3D to benefit from the experience of Marlin, used on thousands of printers throughout the world.

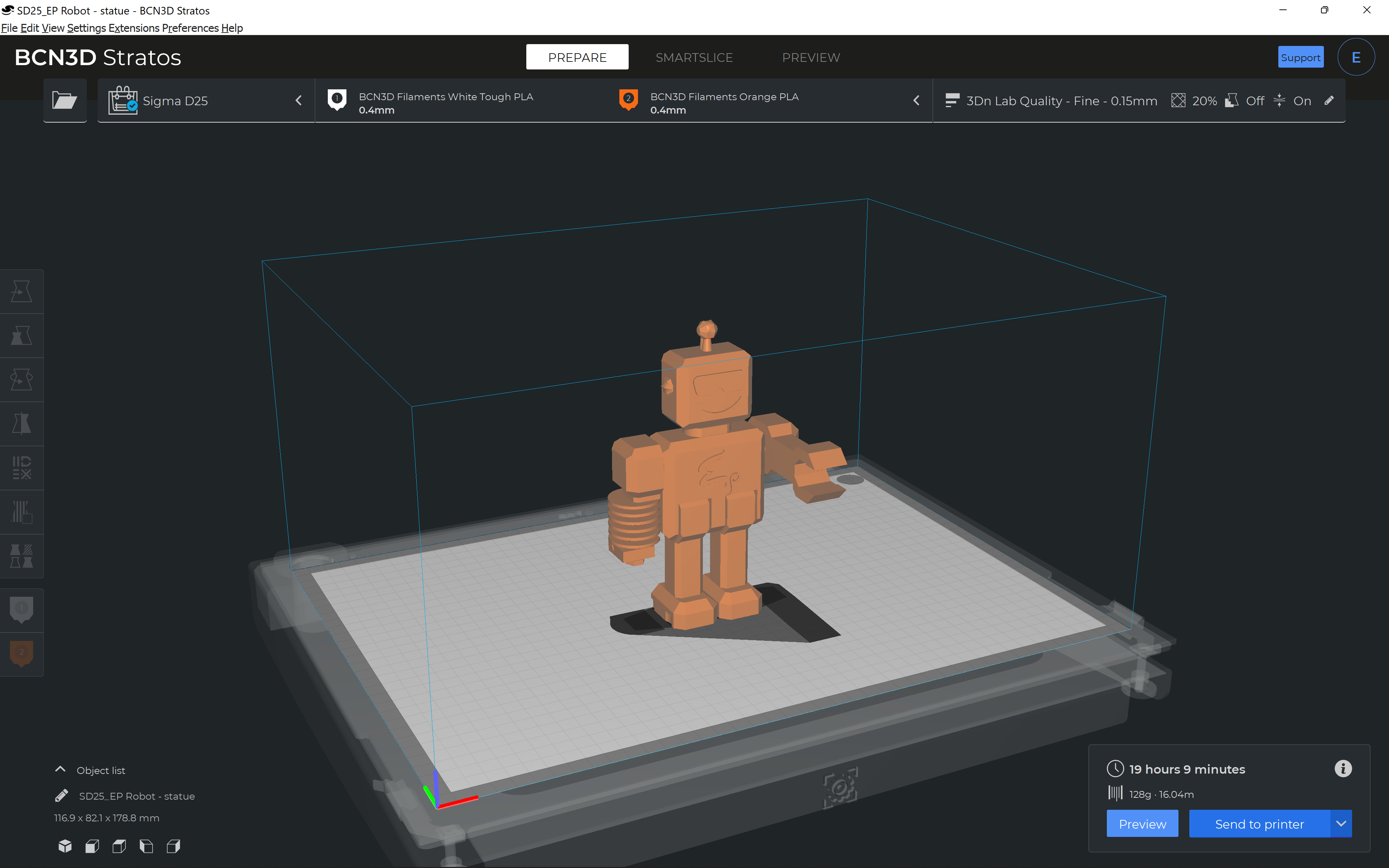

For its slicer, BCN3D used, until recently, a slightly modified version of Cura called BCN3D Cura. In July, BCN3D unveiled its newest software, BCN3D Stratos. This new slicer is still based on Cura, but BCN3D has put more effort into customization, modernized the slicer design, and brought in additional features such as some board grip and bracket settings. Finally, BCN3D has given a logo to its new slicer.

Stratos allows users to take full advantage of the IDEX system developed by BCN3D thanks to the mirroring, duplication and multi-material printing modes. More globally, Stratos allows you to slice your model to prepare it for printing and to send it to the printer via Wi-Fi thanks to the integration of BCN3D Cloud, accessible from Stratos via the connection button. Note that it will always be possible to export the sliced model to an SD card, supplied with the printer, in order to print it without going through the cloud.

Stratos, the slicer developed by BCN3D is based on Cura

Stratos now integrates Smartslice, a subscription-based service that analyzes the part to be printed and provides slicing and material selection advice to the user. A web interface of the BCN3D Cloud brings additional functionalities such as the control of the printer status, the possibility to see the printing progress and the machine temperatures, and more.

Note that BCN3D seems to be very innovative on the software side since it recently acquired Astroprint, a recognized wireless printing software. BCN3D has also collaborated with Autodesk to offer to slice its models directly in the CAD software Fusion 360.

First 3D prints with the Sigma D25

For our first impressions, we used the PLA spools provided with the printer. We first printed a test torture developed by Kickstarter and Autodesk. For this print, we used the profiles preconfigured by BCN3D. Once the print was completed, we removed the pins used to test the tolerances and then evaluated the print following the protocol. On this test, the BCN3D Sigma D25 scores 24.5 out of 30. The printer suffers only from slight shrinkage problems that lead to stringing and the tolerance is only validated up to 0.3 mm. Apart from these minor defects, the printing is successful.

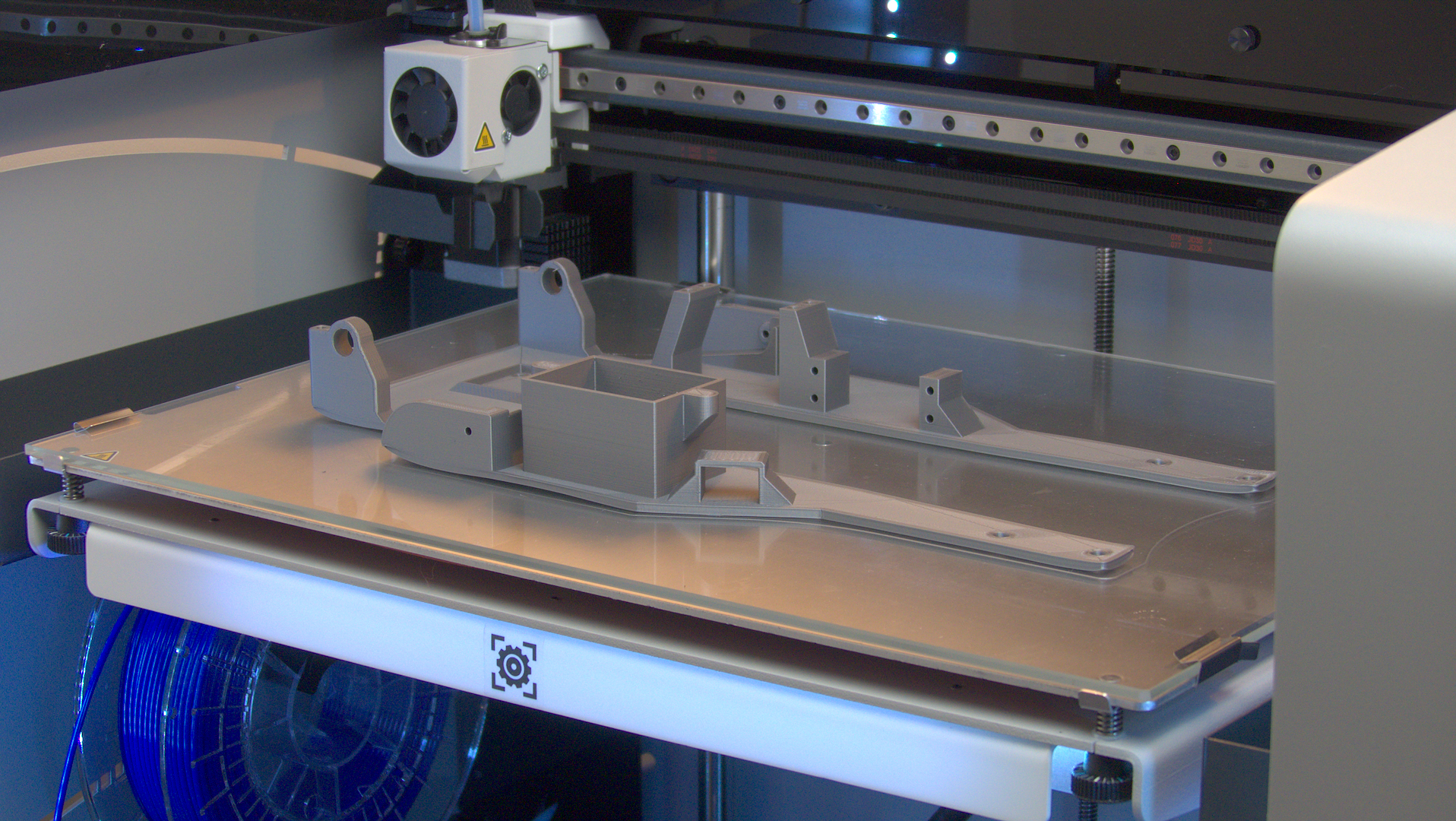

After this first PLA print, we made various PLA prints such as a prototype chassis for a model car, a model of a Porsche 911, a storage station for a glue gun and its accessories, bottle openers, a modular storage system for electronic cables, a flower pot, etc. All these prints went smoothly and attest to the repeatability that the Sigma D25 offers.

The width of the D25 platform allowed us to print prototypes for a thermal car chassis

During our first prints, we noticed that despite the initial plate calibration, the first layer of our impressions was not perfectly flat. To solve this problem, we performed a mesh levelling compensation.

To finish with the PLA prints, we wanted to take advantage of the IDEX double-extrusion system developed by BCN3D by printing a keychain of a two-color octopus. The model is printed in one piece and does not require assembly. Once the printing is finished and the part is taken out of the tray, the octopus wiggles freely.

The Sigma D25’s duplication mode allowed us to print bottle openers and phone holders simultaneously, cutting the printing time in half. In the same way, we were able to print two pencil pots in vase mode thanks to the mirror mode.

The Sigma D25’s IDEX system allowed us to combine 2 different colors when printing our moving octopus

The IDEX system also allowed us to experiment with PVA, a soluble filament with which we were able to print a model of a Mazda MX5. The car itself is printed in PLA while the supports are in PVA. The cleaning of the supports is easy since it is enough to let the part soak in warm water for a few hours, before coming back to the final part. The use of soluble supports means that there will be no traces of supports on the model, considerably reducing post-processing.

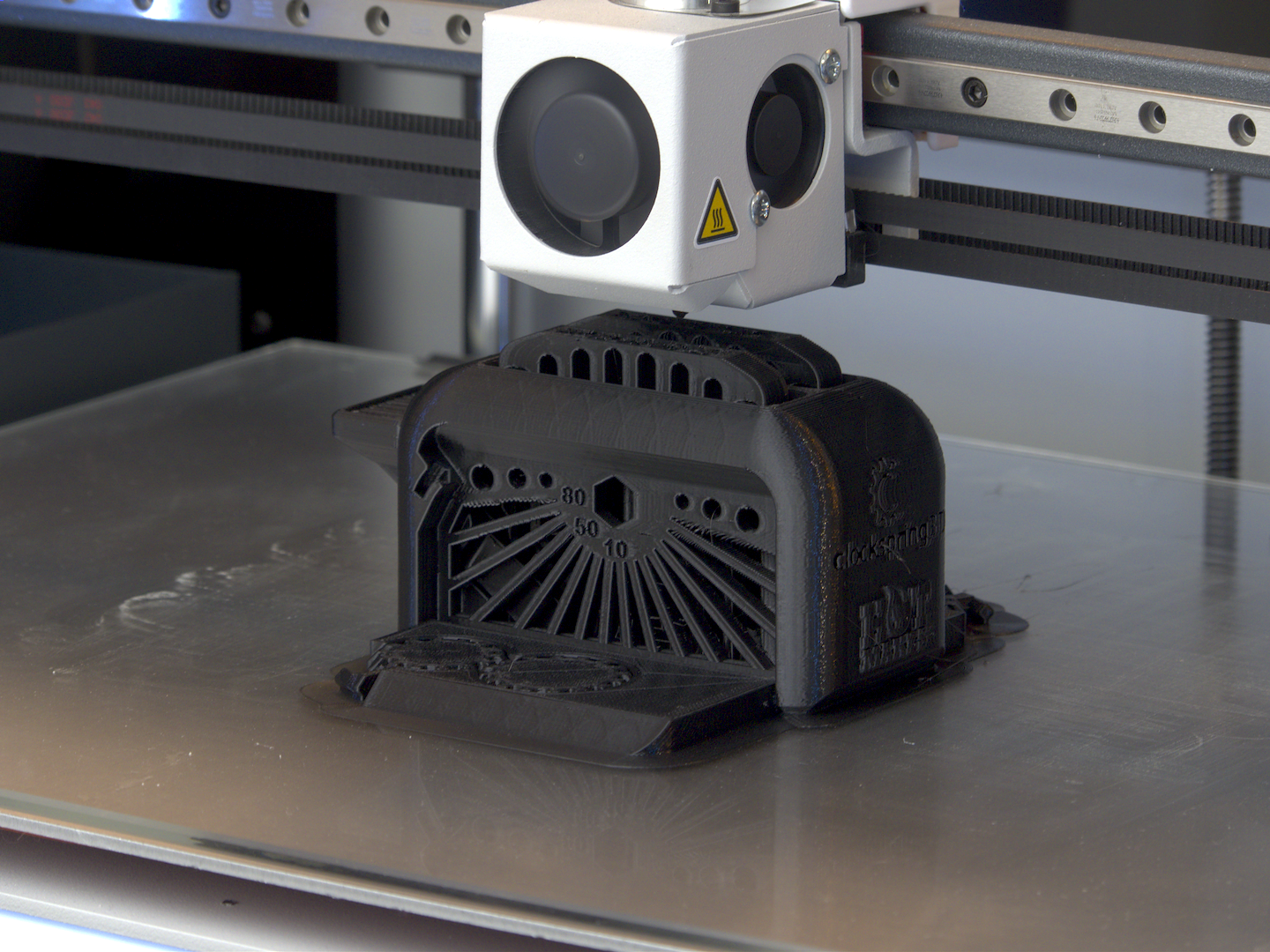

After these tests, we experimented with PETG. This polymer must be printed at a slightly higher temperature than PLA but the Sigma D25 was able to print a toaster shaped torture test without any concern. This torture test confirms the tolerance of 0.3 mm as well as the ability to print unsupported angles up to 60°. The toast popped up as expected when the lever was pressed.

We finally printed a laboratory jack. The model prints in one piece and once the piece is removed from the print tray, the screw can be turned to raise the jack tray.

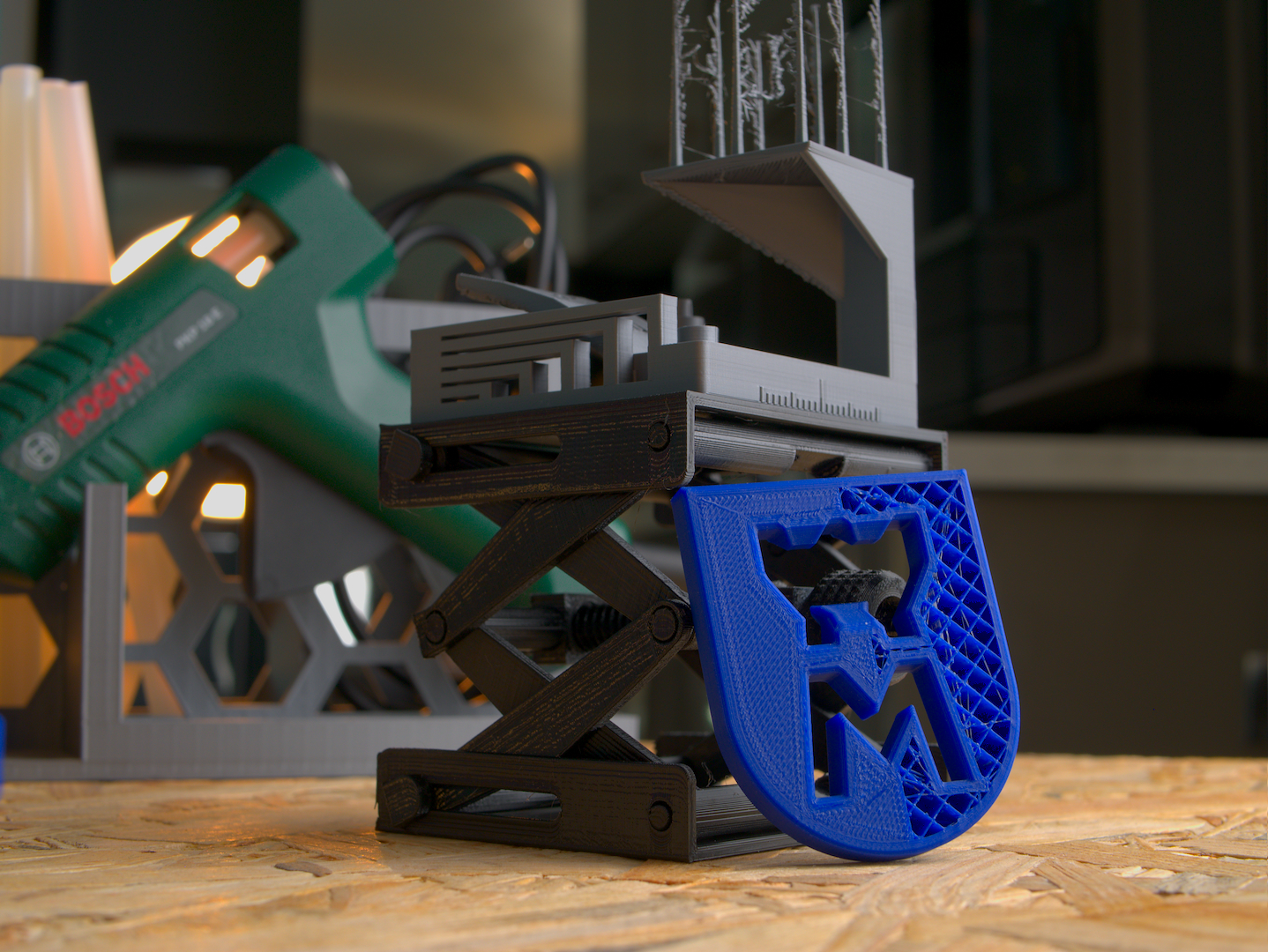

Laboratory jack printed using PETG, an FDM test, glue gun station and bottle opener printed in PLA

Various office accessories printed using the D25

A low-poly Porsche 911 printed by the Sigma D25

This torture test allowed us to judge the PETG printing performance of the D25

Find all of our 3D printer tests in the 3Dnatives Lab

Conclusion

- 3D Printer Features and Accessories 9/10

- Software 9/10

- Print Quality 8.5/10

- Ease of Use 9.5/10

Pros:

– Dual independent extruders

– Reliability/Repeatability

– Printing volume

Cons:

– Lack of a closed building chamber

– Price

BCN3D has imagined its range of 3D printers as a set of complementary machines, made to co-exist within the same production workshop. The Sigma D25 is the entry-level printer of the brand, and allows users to benefit from the IDEX technology, thus using a system of double independent extruders at a relatively attractive price. After more than 300 hours of printing with this 3D printer, we can certainly attest to its reliability.

BCN3D has also understood the importance of good software in the user experience. As such, the manufacturer has recently focused its efforts on a redesigned and improved version of its slicer called Stratos as well as a remote control tool, the BCN3D Cloud. Despite the absence of a closed building chamber, limiting the choice of possible materials and a relatively long heating time of the plate, the D25 is able to print all the parts we attempted.

At a price of €3,495 without tax ($3,995.00), the D25 is a 3D printer that will easily lend itself to the creation of various models in standard thermoplastics (PLA, PETG, PVA, BVOH…) and will allow users to quickly start serial FDM production thanks to its duplication or mirror printing modes.