3DM to Rollout Innovative SLS 3D Printers in Early 2024

As additive manufacturing continues to industrialize, larger-scale production is also increasingly important. However, this can be difficult to achieve. Hence, there is a growing focus on selective laser sintering (SLS). This polymer 3D printing process is well-known for its industrial production capabilities as it allows for the creation of many parts on the same powder bed. But that does not mean it is not without its limitations, notably when it comes to optimal sintering for the powder materials. It is for that reason that startup 3DM has been developing its own innovative technology which they hope will address these problems while keeping the benefits of SLS, including high resolution, fine details and, of course, the possibility for high-volume production. Now the company plans to launch the first batch of its new printers for testing in 2024.

As mentioned, SLS has gained popularity in recent years due to its vast capabilities. In fact, it has become so widespread that the SLS 3D printer market is expected to grow from its worth of about $343.6M in 2020 to $1.438B by 2027 according to a study from Research and Markets. But still, to truly challenge established processes as well as further push the growth of AM in general, innovation is key, such as the new process from 3DM. The rollout of their solution could be integral to the additive manufacturing market and is why it is so important for early users to adopt and test the printers. We took a closer look at what you can expect.

The core of 3DM’s technology is its innovative beam head (seen here in both closed and open forms)

What Can You Expect from 3DM’s New SLS 3D Printer?

As the rollout will not be until early 2024, the printers themselves are not fully confirmed with their final specifications. That said, we already have an idea. Indeed, in our interview with 3DM early in the year we explored the company’s technology more in-depth, which they expect will transform SLS 3D printing. How will this be done? Well, it all starts with the lasers.

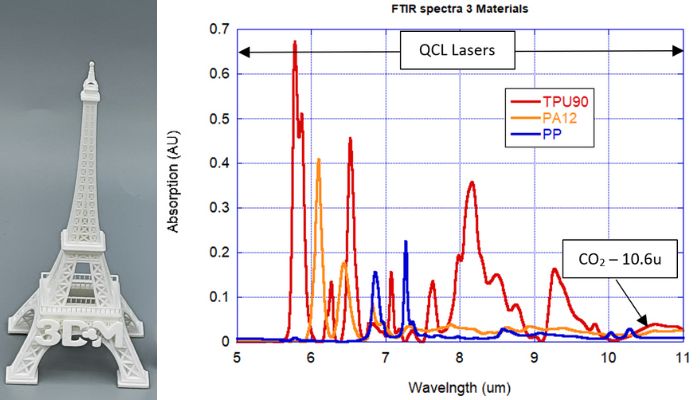

3DM’s SLS technology rests primarily on its proprietary, novel Quantum Cascade Laser (QCL). These semiconductor lasers have been developed specifically by the company for 3D printing, most importantly through the ability to tune the wavelength emitted to meet the optimal melting behavior of the respective thermoplastic. In theory, this means that the technology is not limited by either material or application and can draw out the full potential of any material. Plus, the company has shown a strong willingness to expand its material production.

Indeed, they have stated that they welcome users to alert them to new potential materials that need analysis, particularly those well suited to high-volume production. Another unique feature is that on each printer, four 8W (or better) beam heads can be combined, allowing for targeting of two different wavelengths at once in the printer. Moreover, for printing itself, there is a continuous powder feed option as well as four IR–dedicated heating elements to maintain build temperature, which maxes out at 220°C. The build volume as well is noteworthy, at 220 x 200 x 350 mm and with a layer thickness that goes between 40µ and 120µ. Though, as mentioned, these specifications are subject to change, they still show the impressive results that can be expected with this soon–to–come 3D printer from 3DM.

With 3DM’s patented lasers, it is possible to optimize the wavelengths to different materials’ optimal melting temperature unlike with traditional lasers, shown in the graph on the right above. This allows for the creation of detailed and fully optimized parts such as the one shown on the left.

Who Will Benefit?

Currently, 3DM is working with early adopters of the technology. But who exactly can expect to benefit? Similar to more standard SLS, there are many sectors where applications will be a good fit. For example, in the consumer goods and medical fields where customization is valued, but also transportation and services. The latter two industries are especially important due to their vast needs when it comes to materials and printing flexibility.

Additionally, considering the other advantages, including the superior material properties, smooth surface and more, we are sure to see even more applications in the future as well. If you would like to learn more about the printer rollout or become an early adopter, you can get in touch with 3DM HERE.

What do you think about 3DM’s expected printer rollout in early 2024? Will you be becoming an early tester of this technology? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: 3DM