#3DExpress: UK MOD Outlines Additive Manufacturing Adoption With New Advanced Manufacturing Strategy Paper

This week has been full of news in the field of additive manufacturing. We’ll start this latest edition of #3DExpress by talking about the new Advanced Manufacturing Strategy unveiled by the UK Ministry of Defence before turning to the newest product from Revo Foods, a Black Cod alternative made from mushroom proteins. Next up, PioCreat has launched its newest resin solution on Kickstarter, which it hopes will be a more accessible option for users and Fraunhofer has a new project that transforms packaging waste into material for additive manufacturing. Last but not least, Trump has qualified titanium powder from 6K Additive on its machines. Happy reading and have a great weekend!

UK MOD Outlines Official Advanced Manufacturing Strategy

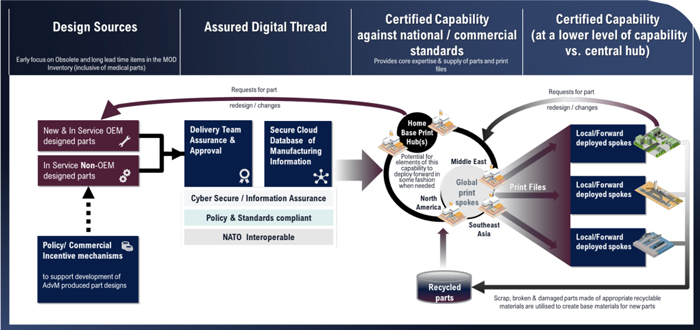

Following in the steps of the United States, the UK Ministry of Defence (MOD) has officially published its “Defence Advanced Manufacturing Strategy.” The first to come from the MOD, it officializes the relationship that the UK armed forces already have with additive manufacturing. More specifically, it emphasizes how AM can be used to improve supply chain resilience and benefit from an increased speed of response, shorter lead times, access to previously obsolete parts and improved environmental and operational sustainability. Aimed at professional working in the defense sector, the Defence Advanced Manufacturing Strategy sets out the risks involved in obtaining the previously mentioned benefits as well as the activities required for mitigation. It builds upon previous work done by the MOD to adopt AM including Project Tampa.

Photo Credits: UK MOD

Revo Foods Launches Black Cod Alternative

Also known as “sablefish”, black cod is a fish renowned for its melt-in-the-mouth texture. And now, Revo Foods has unveiled a black cod fillet made with mushroom proteins and microalgae oils. This composition, dubbed EL BLANCO, is 3D printed on the extrusion machines of the Austrian startup, which has already produced a 3D-printed salmon fillet. The cod fillet is said to be high in omega-3 fatty acids, with a layered texture to preserve the full flavor of the fish. xNmThe main ingredient is mycoprotein, derived from fermented mushrooms. One of its advantages is its ultra-fast growth – it doubles its biomass every five hours – making it a widely available component. EL BLANCO should be available in Austrian and German supermarkets very soon, from April 2025!

Black cod with spicy mango (photo credits: Revo Foods)

PioCreat Launches HALOT-X1 on Kickstarter

Next up this week is PioCreat, a subsidiary of Creality. It announced this week the launch of the HALOT-X1 16K resin 3D printer on Kickstarter. With a starting price of $399, this device seeks to make resin 3D printing more accessible through features that optimize the process without compromising professional quality. Among its main features, it highlights the ability to start printing immediately without prior adjustments. Its new motion system improves stability and reduces imperfections. In addition, the manufacturing plate with quick-release mechanism facilitates the removal of models without damaging them. The intelligent exposure system with 92 light zones optimizes printing and extends the life of the 16K LCD screen. Furthermore, the AFU system automatically manages the resin, including feeding, recycling and heating to improve performance at low temperatures. With these innovations, PioCreat’s HALOT-X1 promises precision and ease of use for users new to the technology.

Photo Credits: PioCreat

Transforming Packaging Waste Into 3D Printing Material

In Germany, 5.6 million tons of plastic packaging waste are generated annually, of which less than one third is recycled. Faced with this problem, the Fraunhofer Institute, in collaboration with the Hochschule Bremen, has developed a method to transform this waste into 3D printing material. The process begins with the collection and purification of polypropylene from sorting plants. Using advanced techniques, such as flotation separation and near-infrared technology, a purity level of more than 99.8% is achieved. The material is then ground, dried and extruded at over 200°C to create homogeneous filaments suitable for 3D printing. This breakthrough not only contributes to the circular economy, but also responds to EU regulations, which require higher recycled content in plastic packaging by 2030 and 2035.

Photo Credits: Fraunhofer

TRUMPF Qualifies 6K Additive Titanium Metal Powder on Its TruPrint systems

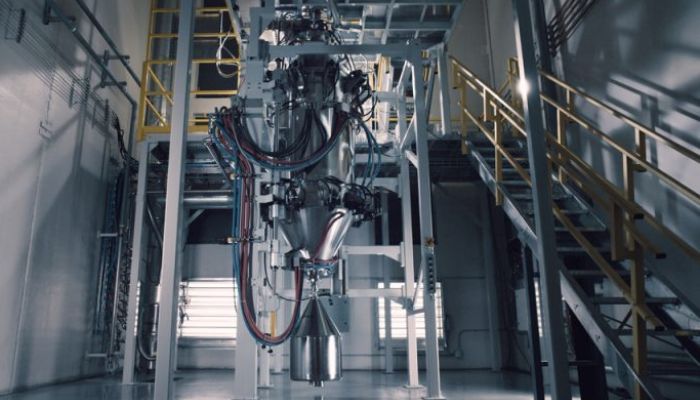

For TRUMPF, the combination of a high-quality printing system and materials is the recipe for success for satisfied customers. As the demand for more environmentally-friendly materials grew louder among its customer base, TRUMPF teamed up with 6K Additive and qualified a titanium metal powder for the TruPrint systems.6K Additive is one of the first manufacturers of powders for additive manufacturing to prioritize sustainable resources. The qualification of the titanium powder enables customers of both companies not only to produce high-quality components for high-performance industries, but also to achieve their sustainability goals. “Having 6K Additive’s titanium sustainable powder added as an approved qualified powder, ensures customers get the quality assurance with the added value of driving down their CO2 footprint,” emphasizes Dennis Pede, Materials Engineer at TRUMPF, and Frank Roberts, President of 6K Additive, adds, “We continue to hear from our aerospace and defense customers asking us to help lower the barriers for qualification for their applications. The collaboration between our two companies did just that by ensuring the machine and powder are qualified ahead of their own internal qualification, which will streamline the customer’s process into production faster. We are excited to work with the TRUMPF team on titanium and other powders in our portfolio going forward.”

6K Additive’s UniMelt® technology enables precise spheroidization of metal powders while controlling the chemistry and porosity of the final product without contamination (photo credits: incus media)

What do you think of the new Advanced Manufacturing Strategy for additive manufacturing from the UK MOD? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.