3DExpress: The New iPhone Air Features 3D Printed USB-C Port

3D printing has finally made its way into the iPhone! In this week’s 3DExpress, we’re covering stories that showcase the growing adoption of additive manufacturing: Siemens Energy reported its use of EOS 3D printers, Caracol announced an expanded presence in North America and SprintRay revealed the acquisition of EnvisionTec’s dental solutions division. To round things out, we take a look at Raise3D’s latest machine. Stay tuned and enjoy the read!

The New iPhone Air Features 3D Printed USB-C Port

Apple has set an ambitious goal: to be carbon neutral across its entire company by 2030. To achieve this, the tech giant is targeting its three largest sources of emissions: materials, electricity and transportation, while also embracing innovative manufacturing technologies. One of the most exciting developments is the integration of 3D printing into its production processes. In its latest announcement, Apple revealed that the new iPhone Air (at just 5.6 mm, the thinnest iPhone ever!) will feature a titanium USB-C port produced with additive manufacturing. The 3D printed design makes the port both thinner and stronger, while reducing material use by 33 percent compared to traditional forging methods. The iPhone Air will also be composed of 35 percent recycled content, including 80 percent recycled titanium and 100 percent recycled cobalt in its battery. Apple is also applying additive manufacturing to other products: the new Apple Watch 11 will feature a 3D printed titanium case, underscoring the company’s growing investment in the technology. With these steps, Apple is signaling its commitment to climate goals but also its confidence in 3D printing as an enabler of greener, more resource-efficient consumer electronics.

Apple’s new iPhone Air is the thinnest iPhone ever, at 5.6mm thick.

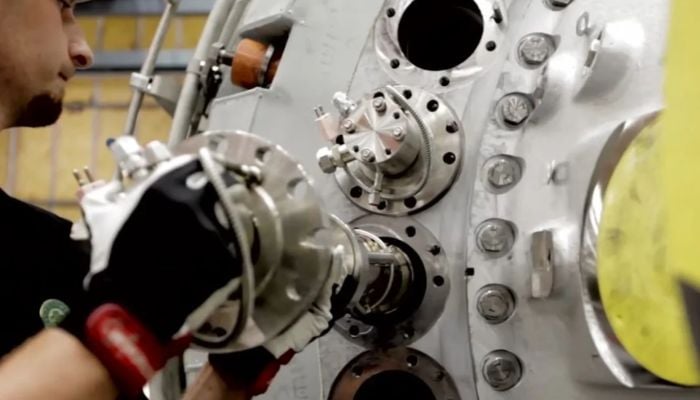

Siemens Energy Uses EOS 3D Printers

Siemens Energy is increasingly relying on 3D printing technologies to make the maintenance and repair of gas turbines more efficient and cost-effective. To this end, the Swedish company is now using a modified EOSINT M 280 metal 3D printer from German manufacturer EOS. The focus is particularly on heavily stressed components such as burner tips, which are exposed to extreme temperatures of over 1000°C in the hot gas flow path of the turbines and therefore wear out regularly. In the past, damaged parts were replaced by laborious cutting and subsequent welding – a time-consuming and costly process. With the 3D printer, the process can be completed directly using additive manufacturing. The system has been specially adapted for this purpose to be able to process larger components (up to 800 mm in length) and is equipped with optical measuring systems, cameras, and appropriate software for precise monitoring of the process. And it’s worth it – repair time can be reduced by up to 90%, which drastically reduces downtime. In addition, older components can not only be repaired, but also specifically improved and brought up to the latest state of the art!

Photo credit: EOS

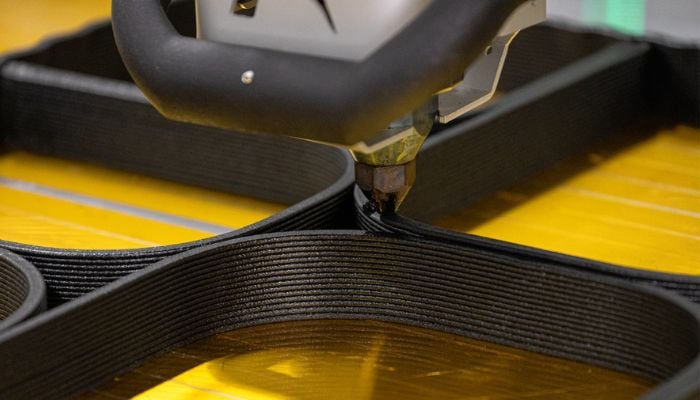

Caracol Strengthens Its Presence in North America:

The Italian company Caracol intends to increase its presence in the US market in the future, as evidenced by the opening of its new US headquarters in Texas. This production center was opened just a few weeks ago. Caracol plans to significantly expand the development and manufacture of its large-format 3D printing systems in the approximately 930 square meter facility. The aim is to meet demand from the US. It will also support Caracol in its plans to shorten delivery times and work more closely with local partners. The center combines research and development, application development, and production of the company’s own Heron AM and Vipra AM platforms. CEP Francesco De Stefano notes: “When we opened our first Austin office in 2023, it was about establishing a presence; now it’s about building capability. This expansion means faster progress, closer collaboration with our customers and solutions designed for their unique challenges — not to mention supporting domestic production in the U.S.”

Photo Credit: Caracol

SprintRay Strengthens Its Expertise in Dental 3D Printing

This week, resin 3D printer manufacturer SprintRay announced the acquisition of the dental solutions division of EnvisionTec, formerly Desktop Health. It is taking over the trademarks, patents, inventory, and other intellectual property. To give you an idea, EnvisionTec has more than 200 patents over the last 20 years, an extensive portfolio of materials, and multiple users around the world. This acquisition should enable SprintRay further to establish itself in the dental additive manufacturing market. Amir Mansouri, PhD, co-founder and CEO of SprintRay, concludes: “SprintRay’s acquisition of EnvisionTEC’s dental portfolio ensures existing customers continue to have the tools and support they rely on, while also strengthening our position in dental labs.Our mission to transform dentistry through accessible, reliable 3D printing technology hasn’t wavered. This strategic move reinforces that commitment.”

SprintRay offers a complete range of products for dental 3D printing. (Photo Credits: SprintRay)

Raise3D Unveils a New Machine

At the Fabtech trade show held this week in Chicago, American manufacturer Raise3D unveiled its latest 3D printer, the E3. It is an IDEX solution, compatible with a wide range of materials, with a higher printing speed and an extrusion temperature that can reach 330°C. It is capable of quickly printing flexible materials such as TPU (150 mm/s) as well as composites (200 mm/s), all at a price of less than $2,500, which remains relatively affordable for the market.

What do you think of Apple’s use of 3D printing? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Apple