#3DExpress: The First Metal 3D Printer Is Going to Outer Space

Once again, it is time to take a look back at some of the news that has marked the additive manufacturing sector this week. And we’re starting with a piece of news that truly does show that not even the sky can be a limit for 3D printing, as it involves exploring space. French company AddUp has announced, in collaboration with Airbus Defense & Space, that it will be sending the first metal 3D printer into space! It should enable the creation of spare parts aboard the International Space Station. We also take a look at the first FDA-certified 3D-printed gastric device, an unprecedented achievement in the medical sector. We’ll also be talking about Boston Micro Fabrication’s growth, submicron 3D printing and the completion of the largest 3D printed house in Europe. Happy reading and have a great weekend!

Airbus Will Send a Metal 3D Printer into Space

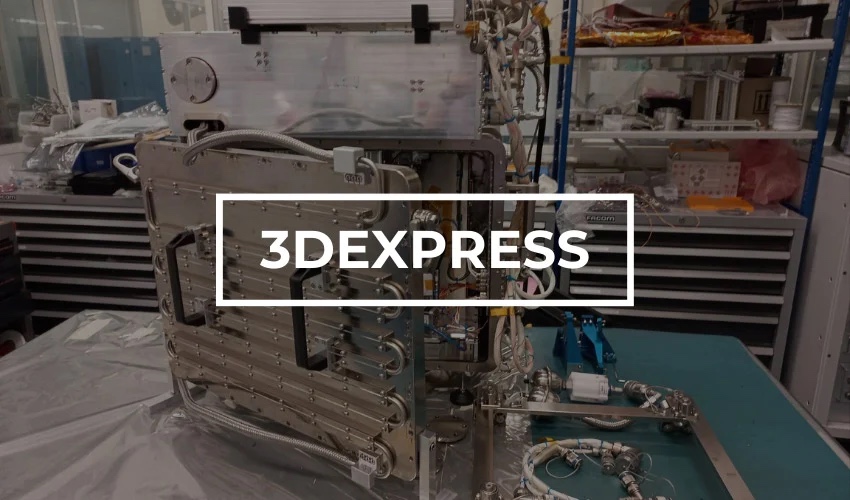

Metals 3D printing solutions manufacturer AddUp has just announced the delivery of a working metal 3D printer in space to the European Space Agency. In collaboration with Airbus Defense & Space, the company has developed a customized metal solution capable of designing parts in microgravity conditions aboard the International Space Station. The project, which began in 2016, marks a milestone in space exploration. The machine is due to be installed on board the Columbus scientific module and will enable the production of four parts. These will then be returned to Earth for analysis, the aim being to make metal additive manufacturing viable in space. This could open up a host of possibilities for astronauts, including the manufacture of spare parts on demand.

Test parts made by the metal 3D printer before its launch into space (photo credits: ESA)

Triastek’s 3D Printed Gastric Device Receives FDA Clearance

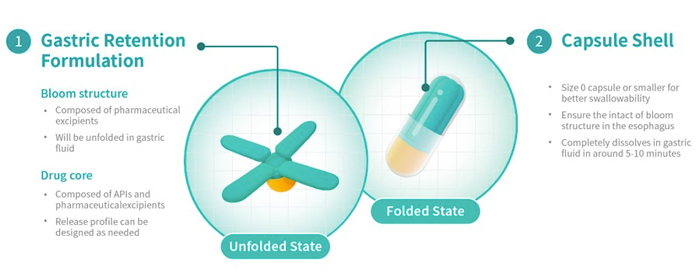

We continue this #3DExpress with Triastek, which announced recently that its 3D-printed gastric device has received FDA clearance. Named T22, the model has become the first 3D-printed gastric retention device to receive this certification. The component was created using Triastek’s proprietary melt extrusion and micro-injection molding (MED&MIM) process. This development could benefit the treatment of pulmonary arterial hypertension and chronic thromboembolic pulmonary hypertension. T22 could reduce the frequency of administration to once-daily, simplifying the dosing regimen and improving compliance. Following this approval, Triastek said it was preparing to launch clinical studies with T22 to accelerate product development.

The 3D-printed gastric device (photo credits: Triastek)

Scrona and Avantama Enable Submicron 3D Printing

A collaboration between Scrona and Avantama has recently produced satisfactory results: the technology of ETH spin-off Scrona, combined with Avantama’s materials, has proven capable of 3D printing on a sub-micron scale for the manufacture of MicroLED displays. Avantama manufactures high-performance quantum dot inks with very high absorption coefficients, which are particularly well suited to Scrona’s 3D printing process. Meanwhile, Scrona’s electrohydrodynamic (EHD) inkjet technology enables very high-viscosity inks to be processed. Viscosity can be much higher than that of conventional printheads. With EHD technology, the material does not drip from the nozzle, but is extracted from it, enabling micrometer resolutions to be achieved. This makes the process particularly attractive for the manufacture of semiconductors and microdisplays.

Photo Credits: Scrona

Boston Micro Fabrication Has Achieved 30% YoY Growth

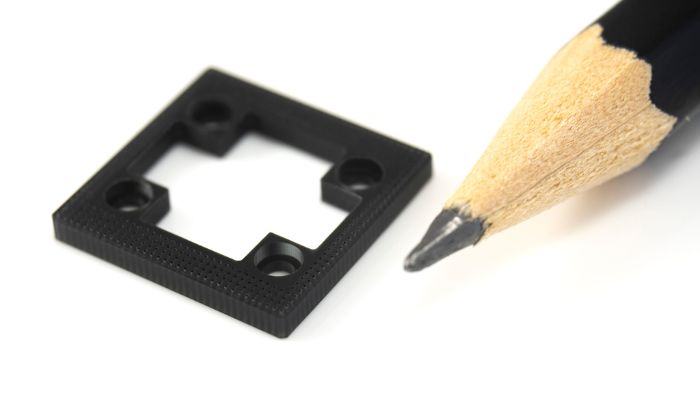

Boston Micro Fabrication, which is well-known for its microscale additive manufacturing solutions for ultra-high precision applications, has announced that it achieved 30% year-on-year growth after a landmark 2023. While many in the AM market have been struggling, BMF, it se ems, has been soaring. Indeed, in the same press release, the company notes that it also recently secured its Series D Funding, launched in new markets including dental, and expanded its San Diego Research Insititute (SDRI). Expanding on the news, John Kawlo, CEO of BMF, commented, “Amid a challenging economic environment on both a global stage and for the 3D printing industry, we are very proud of the progress made over the last year to help our customers push the boundaries on what is possible with our technology. And while a lot of this success is due to strong execution from our team, much of it is based on our product-market focus and the fact that we are building a high value, differentiated business.”

BMF is known for its additive manufacturing solutions for microscale parts (photo credits: BMF)

Europe’s Largest 3D Printed House Completed in Heidelberg

Europe’s largest 3D-printed house is finally ready. Located in Heidelberg, Germany, it took 170 hours to print using a special concrete developed by Heidelberg Materials. It’s worth noting that it wasn’t easy for the owners to fit a roof over the undulating shape of the house. Nevertheless, the project has now been completed and the keys handed over this week. IT company HeidelbergiT is now moving into the building. Despite the challenges, this 3D-printed house can be considered a pilot project for home 3D printing.

Photo Credits: Heidelberg Materials

What do you think of this metal 3D printer from Airbus and AddUp which will be going into Outer Space? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.