#3DExpress: Partnership Seeks to Further Silicone 3D Printing

In this week’s 3DExpress, start off with a new French partnership between Lynxter and 3Deus that could help advance silicone additive manufacturing in the industrial and healthcare sectors. Then learn about Creality’s latest launch and how the combination of chocolate and honey with 3D printing could make us healthier. Last but not least, the South Korean military is solidifying its use of 3D printing and 3plus3D announces the sale of 100 super-metal metal PBF machines. Happy reading and have a great weekend!

French Partnership to Advance Silicone 3D Printing

Bayonne-based manufacturer Lynxter announced this week that it has signed a partnership agreement with 3Deus Dynamics, the French company behind the Dynamic Molding process. This technology involves the deposition of materials into powder, thus doing away with gravity and printing supports. One of the advantages of this process is that it can be used to design highly complex parts, as well as increasing the variety of materials used, especially composites. As a result, Dynamic Molding is highly prized by industries such as healthcare, for the design of anatomical models, or aeronautics and defense. Looking back at the partnership itself, the two French players have combined their skills to offer an innovative machine. The 3Deus Dynamics process can be integrated into the S300X 3D printer, thanks to a solution that includes an adaptation kit comprising a tray, a batch of silicone material and carrier powder, printing profiles, etc. This development is aimed at the industrial and healthcare sectors, and should enable the manufacture of precise, complex parts.

Creality Launches New Multicolor 3D Printer, Hi Combo

With the Hi Combo, Creality has introduced a new 3D printer with features suited not just for beginners but also advanced users. The printer comes 95% pre-assembled, which makes it easy to get started quickly and can print up to 16 colors. This is made possible by the “Intelligent CFS” (Color Filament System) and allows for particularly unusual creations. It has a print volume of 260 x 260 x 300 mm and can print a variety of materials, including PLA, PETG, ABS and carbon fiber-reinforced PLA. Flexible nozzle adjustment is also possible and the speed can be set up to 500 mm/s. A camera is installed to monitor the printing process, which is covered by a flap to protect privacy. In addition to these points, the print quality should also be emphasized, with which Creality wants to impress both beginners and experienced users.

The Creality Hi Combo 3D printer (photo credits: Creality)

Could a Combination of 3D Printing, Chocolate and Honey Lead to Better Health?

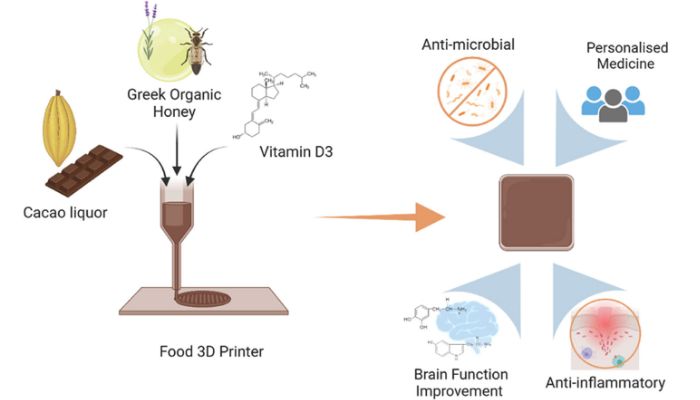

Researchers at Queen’s University Belfast have used 3D food printing to design dietary supplements based on cocoa and honey. The aim is to boost the immune system thanks to a unique blend of ingredients. Specifically, the team explains that they used Greek honey that contains thyme and asfaka (also known as Greek sage), renowned for their antimicrobial and antioxidant properties. This honey was added to the melted cocoa. This new formulation was then introduced into the syringe of the Choc Creator V2.0 Plus food 3D printer and extruded at a temperature of 32.5°C. The resulting supplements then cooled to room temperature. Project leader Professor Dimitrios Lamprou concludes: “Our approach provides a simple way to potentially improve the acceptability of medicines through the taste-masking properties of cacao and honey. Moreover, we have shown the Greek honey variants used in this study possessed inhibitory effects against pathogenic bacteria which could provide further health benefits.”

Photo Credits: Dimitrios Lamprou

South Korea Eyes Expanded 3D Printing Production for Military

Since 2017, South Korea has been using 3D printing to produce parts that may be difficult to procure for warships and tanks. And now, the country has signaled its intent to delve even deeper into the use of additive manufacturing. More specifically, according to The Korea Herald, South Korea’s industry and defense ministries have signed an agreement to expand cooperation in using 3D printing technologies to produce discontinued military parts. This has long been one of the main draws of AM for the military, as shown in the United States with the increased use of the technologies for applications in submarines, ships and planes, now South Korea is the latest to show its growing use of 3D printing in the defense sector. “The project has been improving the operation rate of the country’s defense system by securing parts for warships and tanks, while enhancing South Korea’s manufacturing capabilities in the 3D printing sector,” concluded the ministries in a joint press release.

Engineers operating a 3D printer in the Korean army (photo credits: Ministry of Defense)

Eplus3D Has Delivered Over 100 Super-Meter Metal PBF Machines

In a recent press release, Chinese manufacturer, Eplus3D, a leader in the region for metal AM, announced that it had successfully delivered over 100 units of its super-meter metal PBF machines. Present since 1993 as the first metal PBF 3D printer manufacturer in China, Eplus3D has grown rapidly over the past 30 years and is increasingly moving into the global field. The company has a relatively diverse range of metal 3D printers, including these super-meter metal 3D printers which all have a build size exceeding one meter in one dimension or more and many featuring X, Y, and Z axes all exceeding the meter mark. This latest news shows not just the increased presence of Chinese companies in industrial additive manufacturing but also the increased important of large-format laser powder bed fusion on the 3D printing market.

Installed Eplus3D large-format metal PBF machines (photo credits: Eplus3D)

What do you think of this week’s 3DExpress? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.