#3DExpress: A New Oil & Gas Additive Manufacturing Center in Nigeria

Once again, we are back with #3DEXPRESS to show you all the highlights of the news from the additive manufacturing sector this week! First, a new oil & gas additive manufacturing center has been developed in Nigeria as a way to help revitalize the country’s aging infrastructure. Next, check out the new agreement between Sintx and Prodways for the supply of ceramic materials and the closing of 3Deus Dynamics’ €10 million fund-raising round as the company aims to become the world leader in silicone 3D printing. Then learn more about the five new printers from manufacturer Kings 3D Group before learning more about the validation of the Asiga printer for Desktop Health™’s Flexcera™ family of resins. Enjoy and have a great weekend!

3YOURMIND and RusselSmith Develop an Oil & Gas Additive Manufacturing Center for Oil and Gas in Nigeria

Nigeria is renowned for its vast oil and gas reserves, making it a major player in West Africa’s energy sector. However, many of the country’s infrastructures are aging and in need of maintenance due to a lack of spare parts. The RusselSmith company is working to remedy this situation by producing parts on site using additive manufacturing, thus simplifying maintenance, with a new additive manufacturing centered in Nigeria. As the first supplier of industrial additive manufacturing equipment in West Africa, RusselSmith has received approval from the Nigerian Upstream Petroleum Regulatory Commission (NUPRC) to use non-metallic 3D printing in the country’s oil and gas industry. In collaboration with 3YOURMIND, a Berlin-based company specializing in part identification, RusselSmith aims to improve components for the upstream energy industry. Kayode Adeleke, CEO of RusselSmith, expresses his enthusiasm for the partnership and its potential impact on the regional economy: “We are pleased to partner with 3YOURMIND to improve our solutions, and we look forward to making a positive impact in the region together.”

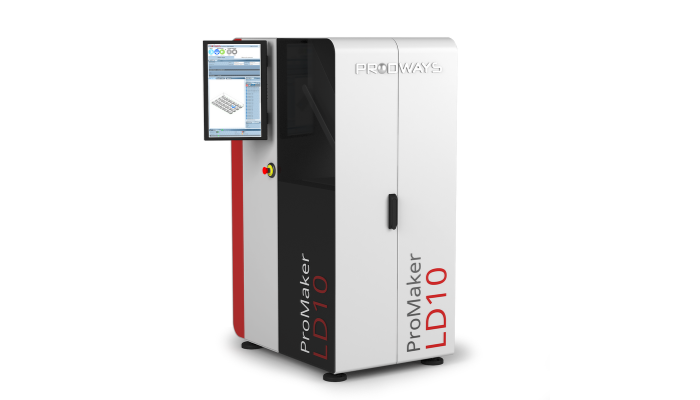

Agreement Between Sintx and Prodways to Supply Ceramic Materials for 3D Printing

SINTX Technologies and Prodways have announced a technical partnership and a supply agreement for ceramic materials for 3D printing. SINTX, an expert in the development and marketing of technical ceramics, will supply its ceramic materials to Prodways, a manufacturer of industrial machinery. Prodways will use SINTX’s Silica and Alumina ceramics on its latest generation of MovingLight machines, specially designed for ceramic additive manufacturing. Vincent Icart, CTO and COO of Prodways, added: “We are delighted to enhance our MovingLight machines developed with SINTX materials, as our combined expertise will enable us to be an end-to-end solution provider for the most demanding ceramic 3D printing applications.”

The ProMaker LD10 3D printer is part of Prodways’ MovingLight DLP range (photo credits: Prodways)

3Deus Dynamics, Future Leader in Silicone 3D Printing?

3Deus Dynamics has successfully closed a €10 million fund-raising round with the aim of transforming the silicone 3D printing industry. The ultimate goal is to become the global forerunner in this field. This will be used to expand their global commercial footprint in the silicone 3D printing sector, reinforce the industrialization of their Dynamic Molding technology from their new French headquarters, intensify their R&D efforts, and integrate the quality standards required by healthcare markets as well as highly specialized industrial markets such as aerospace or defense. All this will be achieved while pursuing a decarbonization strategy for Dynamic Molding products. Julien Barthès, CEO and founder of 3Deus Dynamics, commented: “This round of financing represents a major new step in our ambition to become world leader. Our partnership with Elkem will not only accelerate our international expansion, but also consolidate our leading position in the industry.”

Kings 3D Group Launches Five New Printers

With the TCT Asia 3D printing trade show just a few days away, high-tech company Kings 3D is taking the initiative to showcase its new 3D printers at its Zhuhai factory. The event, organized by its own additive manufacturing research institute, highlights 5 new printers. The first, the DiMetal-500M, is a four-laser powder bed fusion solution, targeting the aerospace, automotive and medical sectors. The second, called LASERDD-660, is a hybrid solution combining DED and subtractive technologies in a single machining center. The third, the HSLA-400, is a high-speed SLA printer with a print volume of 200x160x300 mm. The fourth, the BJ-M400, is a Binder Jetting solutions for metals such as aluminum, copper and titanium alloys. Finally, the DED-A800, with a print volume of 600x400x400 mm, follows the DED process and is compatible with metals such as carbon steel, stainless steel and aluminum alloys. By expanding its product range, Kings 3D Group, formerly specialized in SLA 3D printers, reinforces its position as a leader in additive manufacturing in China.

Desktop Health™ Announces Asiga Printer Validation for Flexcera™ Family Resins

Desktop Health has announced that its family of popular, FDA 510(k) cleared nanoceramic resins for 3D printed removable and restorative dental prosthetics has been validated for use on Asiga 3D printers. Asiga is the second third-party hardware provider to validate the resins for use on its 3D printers, with more expected to come, according to a press release from Desktop Health. Ric Fulop, CEO of Desktop Metal, confirms, “Flexcera is an undeniable leader in the dental market for 3D printed nanoceramics, and we continue to make this popular choice available to other high-powered platforms. We are absolutely delighted to welcome Asiga customers into the Flexcera family. Asiga has one of the largest installed bases of DLP® printers in both North America and Europe, and we look forward to more customers being able to enjoy the material.”

Photo Credits: Desktop Health

What do you think of this new Oil & Gas additive manufacturing center in Nigeria? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.