#3DExpress: Metal 3D Printing Repairs for Parts Aboard US Navy Ship

In this week’s breakdown of additive manufacturing news, learn more about the validation of Meltio’s technology for use on a US Navy ship, the USS Somerset. In addition, PUMA has opened a creative center with additive manufacturing facilities and machinery, while 3D Systems is selling its Geomagic Software Portfolio. Then learn more about the new textile fiber from Asahi Kasei and Aquafil and the co-founder of Renishaw who has passed away this week. Happy reading and have a great weekend.

Meltio Technology Aboard US Navy Ships

Spanish company Meltio, which specializes in metal additive manufacturing, has achieved a new milestone by implementing its technology on board the USS Somerset, a US Navy ship. This breakthrough follows the successful installation of its system on the USS Bataan in late 2022. Meltio’s technology, which integrates hybrid metal 3D printing, combines additive and subtractive manufacturing processes in a single system, enabling the fabrication of metal parts aboard military vessels. During Exercise Rimpac 2024, the US Navy used a Meltio head integrated into a robotic arm to produce metal components, validating its effectiveness in a real-world environment on the USS Somerset. This innovation has a major impact on naval logistics, improving readiness and operational flexibility. The implementation was made possible through collaboration with Snowbird Technologies, Meltio’s U.S. business partner, and demonstrates how the company’s additive manufacturing is improving operations in the defense sector.

Photo Credits: Meltio

PUMA Opens Creative Center With 3D Printing Facilities

PUMA announced the opening of its Studio48 in Germany. In this creative center, which covers more than 500 m2, designers and creative professionals will come together to discuss, develop and test creative ideas and innovative concepts. They will have access to sewing machines for processing textiles and leather, 3D printers and dedicated rooms for product testing and exchange. The aim of this new facility is to drive the sustainable growth of the brand by developing products for top-level performance and to strengthen the PUMA brand. “With the new Studio48, we are creating an important tool to improve the quality of our designs and enhance the brand,” says Heiko Desens, Vice President Creative Direction & Innovation at PUMA. “While many of our products are created digitally, Studio48 will be a space for a different kind of creativity, where our designers from different departments can develop ideas together, share best practices, try out new materials and touch and feel the products they want to make.”

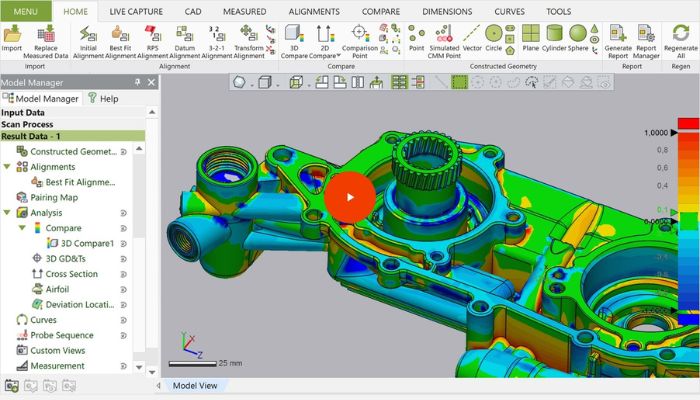

3D Systems Sells Geomagic Software Portfolio

3D systems has announced that it will be selling its Geomagic® reverse engineering, design, and inspection software portfolio to global leader in digital reality solutions Hexagon. Expected to take close in the first half of 2025, the $123 million deal will allow Hexagon to take advantage of the integrated software tool kit which has built a strong user base in areas like reverse engineering. Meanwhile, 3D Systems will be focusing its software platforms to ones that are core to the adoption and application of its 3D printing technology. More specifically, 3D Sprint, 3DXpert and Oqton Industrial Manufacturing OS, which can be used for different technologies and material in large-scale production applications. The company also notes that it will be working to unlock the full potential of these software by working to leverage the capabilities of AI and machine learning.

Photo Credits: Artec3D

New Textile Fiber Developed for Additive Manufacturing

Asahi Kasei and Aquafil have collaborated to develop a new textile material for 3D printing. Specifically, this material is intended for applications in high-performance sectors such as automotive and aeronautics. The innovative composite is based on two key materials: Econyl polymer, a chemically recycled PA6, and Asahi Kasei’s cellulose nanofiber (CNF). The Econyl polymer comes from recycled polyamide waste, such as fishing nets and carpets, giving it a sustainable approach. CNF, derived from cotton lint, offers high heat resistance and improved recyclability compared to glass fiber. The result is a filament that stands out for its ease of molding and strength, making it ideal for the manufacture of 3D printed components. The first sales of this material are planned for 2025 in key markets such as the United States, Europe and Japan.

Photo Credits: Asahi Kasei/Aquafil

Co-Founder of Renishaw Sir David McMurty Has Passed Away

This week, Renishaw announced the passing of its co-founder Sir David McMurty at the age of 84. Sir David was well-known for his work in commercializing the 3D touch-trigger probe for coordinate measuring machines. Under his leadership, Renishaw revolutionized the development of coordinating measuring machines, shopfloor metrology as well as process control while also leading the company’s diversification into areas like additive manufacturing. Today, he leaves a legacy consisting of the thriving company that he founded over 50 years ago, as well as a number of honors.

Photo Credits: Renishaw

What do you think of the use of metal 3D printing on a US Navy ship? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.