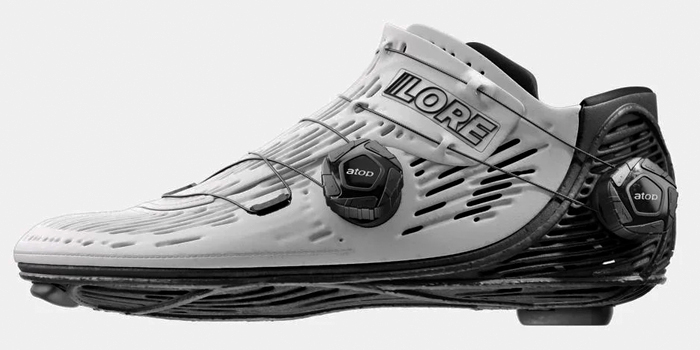

#3DExpress: Lore Introduces the World’s Highest-Performing 3D Printed Cycling Shoe

Once again, we’d like to take a look at some of the latest news from the additive manufacturing market. Starting with new 3D printed cycling shoes from Lore! The shoes are produced from a scan, finished in under 10 minutes, allowing for perfectly customized solutions for every athlete. Next, check out the news from Titomic whose cold spray technology will be used on one of Australia’s largest offshore oil rigs. We also report on the opening of an implant 3D printing center in Australia by German company BellaSeno. Last but not least, we take a look at the new design of car manufacturer NIO’s showroom – featuring 3D printed walls and discuss a new aerospace partnership for Nikon SLM. Have a great weekend!

Lore Cycle 3D Prints Cycling Shoes

LoreTwo are 3D-printed sports shoes designed to fit every athlete. Compared to their predecessors, the LoreOne, the LoreTwo offer more power and efficiency than traditional cycling shoes, but in a highly customized solution. To achieve this customization, Lore Cycle performs a scan of the cyclist’s foot in less than 10 minutes. After optimizing the digital design, the shoes are 3D printed using carbon or nylon as the manufacturing material. Lore explains that in this new version, the company has managed to control some of the more radical design elements of the original shoe to focus on performance. These include greater attention to aerodynamics, as well as improved power transfer and efficiency. The sneakers are expected to sell for $1,349.

Photo Credits: Lore Cycle

Titomic Wins Australia–First Metal 3D Printing Contract for Offshore Gas Rig

For some time, we have seen a growth in metal 3D printing in Australia, notably in the realm of cold spray additive manufacturing. Now, we have yet another milestone as Titomic has announced what they call a groundbreaking partnership with Woodside Energy and Monadelphous to deploy its cold spray technology for corrosion prevention on Woodside’s North Rankin offshore gas platform in the Indian Ocean. Titomic notes that the successful implementation of its cold spray technology could show the benefits it has for on-site repair capabilities, possibly helping to advance maintenance procedures in the global energy sector.

Woodside’s North Ranking offshore gas platform (photo credits: KBR)

BellaSeno to Open a 3D Printing Center

German start-up BellaSeno is looking to expand its activities and has announced the opening of a 3D printing center in Australia, dedicated to the production of 3D-printed implants for the medical sector. The aim is to produce up to 100,000 3D-printed scaffolds for breast implants. These would be resorbable. To achieve this, BellaSeno explains that it will also rely on artificial intelligence and funding from the Queensland State Government. The company’s CEO, Mohit Chhaya, concludes: “We have developed a sophisticated no-touch manufacturing approach for our leading-edge products in soft and hard tissue regeneration. The establishment of this novel, fully automated facility will be globally unique and puts BellaSeno and Queensland at the forefront of creating leading-edge medical scaffolds.”

Photo Credits: BellaSeno

3D-Printed Walls in Amsterdam

If you’re strolling along Amsterdam’s Keizersgracht canal, take the time to stop off at the 7-storey building occupied by electric car manufacturer NIO. In addition to its highly atypical design, which blends history and novelty, it now features a showroom with 3D-printed walls by architecture firm Aectual. Aectual explains that it recycled aluminum from beverage cartons and mixed it with recycled polymers. This mixture was then extruded by robotic arms. When the showroom closes, the walls can be crushed so that the material can be recycled again.

The showroom with its 3D-printed walls (photo credits: Ossip van Duivenbode)

Nikon SLM Solutions and Howco Enter Into Aerospace Partnership

Howco, a processor of high-performance alloys and manufacturer of high-quality components, recently announced the addition of two further metal 3D printers from Nikon SLM Solutions to its fleet of machines. The new SLM 280 PS systems contribute to the manufacture of high-quality aerospace parts from alloy C 103. This high-performance alloy is extremely robust at extreme temperatures. In addition, as part of this extended partnership, Howco gains exclusive 3-year rights to process its alloy for non-military applications on SLM 280 and SLM 5000 systems. “Partnering with Nikon SLM Solutions has equipped us with unparalleled technological support, enabling us to expand into new markets beyond our traditional scope,” said Conrad Kao, Director of Additive Manufacturing at Howco. “These advanced SLM 280 PS systems empower us to enhance our operational efficiency and cater to the intricate needs of the aerospace industry.”

Photo Credits: Nikon SLM Solutions

What do you think of the 3D printed cycling shoes from Lore? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.