#3DExpress: The First Metal 3D Printed Valve Manifold Assembly Installed on an Aircraft Carrier

In this week’s #3DExpress, we start off with yet more news from the U.S. Navy. At Newport News Shipbuilding, a 3D printed metal valve manifold assembly has been installed in an aircraft carrier for the very first time. Next, see how Eplus3D has made large-scale copper additive manufacturing possible and how 3D scanning can help in boat maintenance. Wrap it up with Bosch’s new center for AM in the automotive sector in Europe and a major advancement in 3D printing breast prostheses from Lattice Medical. Happy reading and have a great weekend!

The First-Ever Installed 3D-Printed Valve Manifold on a U.S. Navy Aircraft Carrier

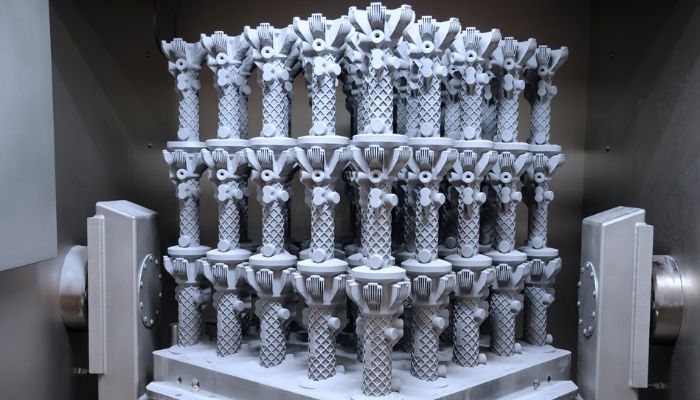

DM3D Technology, a leader in direct metal deposition (DMD) additive manufacturing, has announced the first-ever installation of an additively manufactured valve manifold assembly on a U.S. Navy aircraft carrier at Newport News Shipbuilding (NNS). NNS has been a longtime adopter of AM technologies, using 3D printed components in new nuclear subs and working to develop Copper-Nickel (CuNi) and Nickel-Copper (NiCu) alloy powders for 3D printing due to their suitability for maritime applications. This time, a valve manifold assembly, which allows distribution of a single source of fluid to multiple points on the ship, was made using metal 3D printing and has been installed in a pump room on Gerald R. Ford-class aircraft carrier Enterprise (CVN 80). “What started as a proof of concept quickly turned into a tangible result that is making a meaningful difference to improve efficiencies in shipbuilding,” explained Dave Bolcar, NNS Vice President of Engineering and Design. “The benefits of this innovation will extend well beyond Enterprise (CVN 80), as we incorporate our expertise in additive manufacturing into the fundamentals of shipbuilding.”

The valve manifold assembly in the pump room on Gerald R. Ford-class aircraft carrier Enterprise (CVN 80) (photo credits: DM3D)

Eplus 3D Unveils Meter-Scale, Red-Laser Copper AM

TCT Asia 2025 has closed its doors. But with the Asian AM market booming, it is not surprising to see some of the incredible advancements announced at the show. This includes one from Eplus3D. Building upon the success of its 64-laser EP-M2050 system, the company has now unveiled its capabilities for large-scale 3D printing of pure copper and copper alloys thanks to advanced red-laser technology. Copper can be difficult to 3D printing due to high reflectivity and low energy absorption, Eplus3D has overcome this with its own red-laser technology that is compatible with its existing large-format, multi-laser metal PBF machines including the EP-M2050, EP-M1550, and EP-M1250. To prove it, large parts were on display at TCT Asia, including a φ1030×175 mm CuCrZr impeller that has a 99.97% density while retaining copper’s thermal and electrical conductivity. 3D printed meter-scale copper parts would be well suited for industries like aerospace, automotive and electronics.

Caption: Meter-scale copper parts printed with Eplus3D metal PBF systems (photo credits: Eplus3D)

3D scanning for boat maintenance

Blaupause Bootsbau is a German company specializing in the repair and maintenance of pleasure boats. It recently turned to 3D scanners from Artec3D to facilitate its work. Indeed, many curved surfaces had become too complex to capture in the traditional way, i.e. via single-point lasers. Relying on Artec Leo and Artem Ray II scanners, the company claims to have cut her turnaround times by two-thirds! Martin Dittmer is CEO of Blaupause Bootsbau. He explains, “Before, to measure a deck or a small cockpit, it would take me five or six hours. With Leo, I can scan it in ten minutes. With costs rising across the board, we need to be more efficient, and measurement is a key part of that process.” In addition to greater scanning speed and accuracy, teams can rely on Artec Studio: the tool transforms scanned data into a clear 3D mesh.

Photo Credits: Blaupause Bootsbau

Bosch Invests 6 Million Euros in Mew Metal 3D Printing Center

Bosch is considered one of the most important suppliers of automotive parts in Europe. And in order to secure this supremacy in the long term, the company has now invested millions in setting up a metal 3D printing center at its Nuremberg plant. This also includes the purchase of a new high-performance 3D printer, namely the NXG XII 600 system from Nikon SLM Solutions. This metal printer has twelve lasers and produces up to 1,000 cubic centimeters per hour. With this purchase, Bosch aims to significantly increase the production of metal parts and reduce manufacturing time. This will also significantly reduce the time to market. Sustainability is also an important concern and a central argument for the establishment of the new metal 3D printing center, as Alexander Weichsel emphasizes, “Using the 3D printer to manufacture components not only increases sustainability in production, but also enables Bosch to respond flexibly to fluctuations in batch sizes and offer everything from a single source.”

Photo Credits: Bosch

A Major Breast Cancer Medical Advancement

Lille, France-based start-up LATTICE MEDICAL has announced a new milestone in the medical 3D printing sector. Its 3D-printed, resorbable breast bioprosthesis has been successfully implanted as part of the TIDE clinical trial coordinated by Lille University Hospital. The operation was successfully carried out at the Centre Léon Bérard. The French medtech company also announced the “completion of patient enrollment in Phase I of its TIDE clinical trial for breast reconstruction.” A total of ten women in France and Spain took part in this first phase of the study. We can’t wait to see what happens next!

Photo Credits: Centre Léon Bérard

What do you think of this first 3D printed metal Valve Manifold Assembly on a U.S. Navy aircraft carrier? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.