#3DExpress: FAA Certifies GE Aerospace Engine Made Using 3D Printing

This week’s #3DExpress is full of exciting aerospace news! First, the FAA has certified an innovative engine from GE Aerospace that was made using additive manufacturing. Next, the United States Air Force is calling for 3D printing vendors who can be qualified to create flight-critical parts, a continued sign of the US military’s appreciation of AM. We also have news from across the Atlantic, where the European Space Agency (ESA)’s first metal part 3D printed in Space has come to Earth for testing. After, finish up with some other interesting stories, including the World’s largest 3D printed structure and Versace’s 3D printed outfits on a recent runaway. Happy reading and have a great weekend.

FAA Certifies GE Aerospace Engine That Consumes 18% Less Fuel

The FAA (Federal Aviation Administration) has certified a new 3D printed engine (named “Catalyst”) from GE Aerospace. What makes the Catalyst so special is that it not only consumes less fuel but also offers a higher cruising speed (+10%). The reason this is possible is thanks to the use of additive manufacturing when creating the engine. The 3D-printed parts have enabled a considerable reduction in weight. Around 855 individual parts were replaced by just twelve complex 3D-printed parts. Around a third of the total number of parts were 3D printed. Riccardo Procacci, President and CEO of Propulsion and Additive Technologies at GE Aerospace, sees the certification of Catalyst as a major success: “The certification of the Catalyst engine is a significant milestone for our company and a proud moment for all our team members who have dedicated their efforts to the design, development, and testing of this brand-new European turboprop engine. We are now fully committed to supporting the production ramp-up of the engine towards the entry into service in support of our customers.”

Photo Credits: General Electric Company/NORKIN

The US Air Force Is Looking to Qualify 3D Printing Vendors

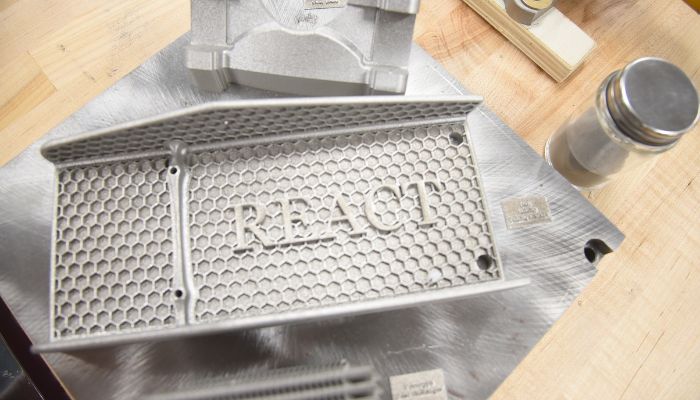

It is no secret that the American defense sector has been investing in additive manufacturing as a way to improve its combat readiness and end supply chain issues. Now, in further proof of that, U.S. Air Force aircraft specialists have sent out a call for 3D printing vendors who could use AM for flight-critical aircraft components. The Request for information (FA8684-QAMVAP) for the Qualification of Additive Manufacturing Vendors for Airworthiness Parts project comes from offices at the Air Force Life Cycle Management Center at Wright-Patterson Air Force Base in Ohio. The qualification of the vendors is a necessary step in order to use 3D printing for flight-critical parts and to that end the Air Force is asking for white papers that provide information on quality management, material, qualification, process validation, design for additive manufacturing, non-destructive inspection, documentation and traceability and adhering to standards like AS9100 or ISO 9001, among other qualifications. You can find out more HERE, interested parties have until April 22, 2025, to email the white papers.

A metal part printed by Air Force Material Command in an earlier project (photo credits: U.S. Air Force photo/Kelly White)

The First Metal Part 3D Printed in Space Is Back on Earth

Last year, we told you about the first metal 3D printed part ever created in orbit at the International Space Station. Now, it has made the long trip back to Earth. This first sample, made last summer, will be tested in the Materials and Electrical Components Laboratory at ESTEC, the ESA’s technical heart, while the second sample, from December, will be handed over to the Technical University of Denmark. The goal? To compare these parts with those printed on Earth in order to understand how microgravity affects the printing process. The results will be critical according to ESA to furthering the possibility of in-space manufacturing, which would enable astronauts to manufacture essential parts, repair equipment and create tools even on remote missions.

Photo Credits: ESA-R. Moorkens O’Reilly

The World’s largest 3D-Printed Structure Is in Dubai Restaurant MYATA

Dubai’s MYATA Platinum restaurant has set a Guinness World Record by integrating the world’s largest 3D-printed structure in terms of volume. To achieve this, it collaborated with Proto21 3D Printing, a company specializing in large-scale additive manufacturing. The project included 23 3D-printed structures that make up the restaurant’s interior and exterior facade, as well as counters, planters and decorative elements. In all, over 10,500 unique parts were printed, totaling 1,190 square meters and 10.2 tons of material. Manufacturing was a technical challenge, requiring three months of continuous 3D printing using a variety of technologies and materials suitable for both indoor and outdoor use. According to Proto21, this project demonstrates that 3D printing has evolved from an experimental technology to a scalable solution for commercial applications, consolidating Dubai’s position as a benchmark for architectural innovation.

Photo Credits: Proto21 3D Printing

3D Printing Used in Versace Fashion Show

LA FERME 3D © is the French specialist in 3D printing training and mass production, known particularly in Europe for its larege 3D printer farm that enables it to address a wide range of needs. The company works with a wide range of professionals, from Michelin-starred chefs to fashion houses such as DIOR. This time, it has put its expertise at the service of Italian brand Versace to design certain pieces for the Womenswear Fall/Winter 2025 Fashion Show held on February 28. We don’t know the exact details of this new collaboration, but one thing’s for sure: the result is stunning! The centerpiece is undoubtedly the red 3D-printed skirt (see below), encrusted with Swarovski rhinestones.

A skirt made using 3D printing at Versace’s fashion show (photo credits: Versace)

What do you think of the FAA’s certification of GE Aerospace’s engine? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.