#3DExpress: Eplus3D Announces New Metal 3D Printer

We are back with #3DEXPRESS to show you all the highlights of the news from the additive manufacturing sector this week! First up, Eplus3D presents its new metal 3D printer, incorporating 36 lasers with the capability to add an additional 26. Next, the European Space Agency announced the launching of the new Ariane 6 rocket, which aims to demonstrate the potential of 3D printing in space, as well as to build infrastructures on the moon and Mars in the future. Moving forward, AM Craft has announced that it has successfully raised €600,000. Next up, the Politecnico di Torino, in collaboration with TÜV Italia and other partners from the aerospace industry, has presented the first results of the European MIMOSA project. Lastly, researchers from the University of Birmingham have recently presented their findings on a new photopolymer resin developed from lipoic acid, enabling the printing of 3D parts from recycled prototypes. Enjoy!

A New Metal Machine from Eplus3D

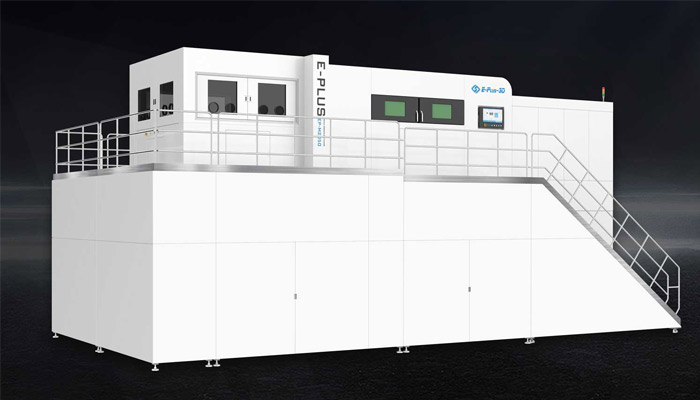

We start this 3DExpress with Chinese manufacturer Eplus3D. This week, it presented its new 3D printer for metal, based on powder bed laser melting. It incorporates no less than 36 lasers and can be modified to add 26 more. Named EP-M2050, it offers a generous print volume of 2050 x 2050 x 1100 mm and a layer thickness of between 20 and 120 microns. Eplus3D notes that this industrial machine is particularly suitable for the production of parts for the aerospace industry, thanks to the quality and precision it offers. Finally, the machine’s fiber lasers have a power of 500 or 700 W, depending on the user’s needs.

The Chinese manufacturer’s new machine. (Photo Credits: Eplus3D)

Ariane 6 Rocket Set to Launch With 3D Printer Onboard

The European Space Agency has just announced the imminent lift-off of the new Ariane 6 rocket, whose flight will have a number of objectives, both in terms of space exploration and the testing of new technologies. The Replicator mission, launched by start-up Orbital Matter, aims to demonstrate the full potential of 3D printing in orbit and, ultimately, to build infrastructures on the Moon and Mars. The technology developed by the startup operates in microgravity, without generating heat during the printing process. During the Ariane 6 flight, its CubeSat 3D printer is expected to print a 50 cm-long beam at an altitude of 580 kilometers – a first for this machine, which has so far only proved its worth on Earth.

Jakub Stojek, CEO of Orbital Matter, and Robert Ihnatisin, CTO, with a replica of the CubeSat. (Photo Credits: ESA)

AM Craft Raises Funds

The startup, which specializes in the production of 3D printed equipment for the aerospace industry, has just raised €600,000. The company’s CEO, Didzis Dejus, spoke on this achievement, stating, “The vision is to enable low-cost, rapid sourcing of a large library of parts, delivered sustainably by local certified manufacturing hubs around the world, thereby massively increasing the use of additive manufacturing in spare part sourcing and eventually also OEM manufacturing.”

The AM Craft team. (Photo Credits: AM Craft)

Launch of the MIMOSA Project to Optimize Aircraft Through 3D Printing

The Politecnico di Torino, in collaboration with TÜV Italia and other partners from the aerospace industry, has presented the first results of the European MIMOSA project. The project, which began at the end of 2022, aims to transform aeronautical construction through the combined use of composite materials and 3D-printed metals. On May 15, a conference was held in Turin at the Automobile Museum, where the initial results of the research project were presented to companies in the aerospace sector. By exploiting specific Politecnico patents, the MIMOSA project will produce multi-material structures composed of metal alloys and composite materials without intermediate elements (adhesives or rivets), thanks to the integration of metal additive manufacturing, plasma surface treatments and carbon fibers.

Stefano Pasquino, Sabrina Zapperi from TUV Italia, and Giorgio De Pasquale from Politecnico di Torino. (Photo Credits: Politecnico di Torino).

A New 3D Printing Resin

Researchers at the University of Birmingham this week presented their findings on a new photopolymer resin developed from lipoic acid. This is a natural fatty acid molecule often found in the form of a dietary supplement. According to the team, this resin could be recycled, enabling the creation of finished parts from 3D printed prototypes. Professor Andrew Dove concluded, “Our approach is an important step away from relying on 3D-printable resins made from petrochemicals, which cannot be efficiently recycled. While we still have improvements to make to the properties of the new resin, this research opens up exciting new avenues for development.”

Complex 3D-printed part made from fully bio-sourced resin. (Photo Credits: University of Birmingham)

What do you think about the announcement by Eplus3D of its new metal 3D printer? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.