#3DExpress: Enhanced Ocean Conservation Through 3D Printing

We are back with #3DEXPRESS to show you all the highlights of the news from the additive manufacturing sector this week! First up, QOROX partners with CyBe Construction to leverage 3D printing for artificial reefs, promoting biodiversity and habitat reconstruction for various marine species. Next, American company Honeywell has turned to French manufacturer Prodways to improve the manufacturing process for its turboprop engines. Moving forward, NEVO3D and KIMYA launch a new material for the rail industry, harnessing the benefits of 3D printing for repairs. Wrapping up, Solukon updates its SFM-AT350 Solution, enhancing the system with various upgrades. Let’s get started!

3D Printing and Ocean Conservation

3D printing is increasingly being leveraged to preserve our planet, develop recycling solutions, and protect our oceans and biodiversity. A notable example of this is the project led by Eke Panuku and QOROX in New Zealand, which demonstrates the innovative potential of concrete 3D printing. Collaborating with CyBe Construction, the two partners have created artificial coral reefs, which serve as microhabitats for various marine species. These 3D printed marine crustaceans provide essential shelter, contributing to ocean conservation of marine ecosystems.

(Photo Credits: QOROX)

Honeywell Partners with Prodways

American company Honeywell, known for its solutions in the nuclear, aerospace, and construction sectors, has turned to French manufacturer Prodways to improve the manufacturing process for its turboprop engines. The company turned to ceramic 3D printing technology to design molds for turbine blades. Prior to using additive manufacturing, Honeywell used the conventional lost-wax casting process, which was much more time-consuming and costly. The teams explain that they can now manufacture a turbine blade in 7 to 8 weeks, compared with one to two years previously! Additionally, these 3D printed molds are more resistant to wear and corrosion, and enable a whole series of tests and validations to be carried out much more easily.

(Photo Credits: Honeywell)

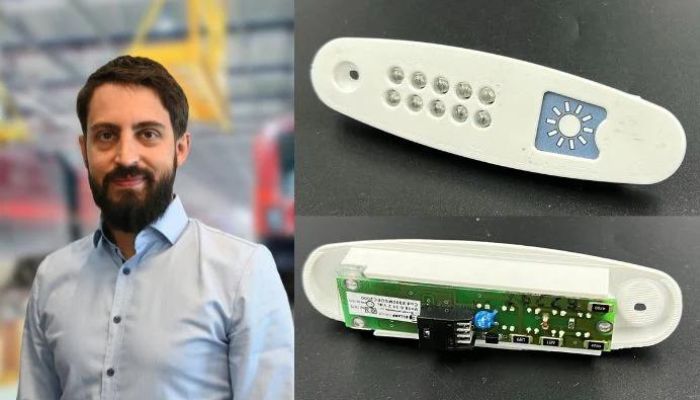

NEVO3D and KIMYA Launch a New Material for the Rail Industry

NEVO3D and KIMYA have launched a new material for the rail industry, capitalizing on the growing use of 3D printing for repairs and components that are no longer produced traditionally. This advancement helps extend the lifespan of existing train components and facilitates efficient maintenance. However, materials must comply with current standards, particularly the fire safety standard EN-45545-2 R1/HL3. NEVO3D (formerly EVO-tech) and materials manufacturer KIMYA have collaborated to provide the Austrian Federal Railways with a certified material specifically for additive manufacturing in trains. Their new solution, based on polycarbonate and E-140, offers cost savings of up to 80%, achieved through reduced material costs and lower requirements for 3D processing printers. The partners aim to support the Austrian Federal Railways in meeting their objectives and to deliver promising material solutions for the railway industry.

(Photo Credits: ÖBB)

Solukon Updates Its SFM-AT350 Solution

Launched in October 2021, the SFM-AT350 post-processing solution developed by Solukon has been upgraded to offer greater capacity. The depowdering system can now handle larger and heavier structures. While it could originally only handle parts up to 60 kg and 350 mm in the X axis, the new version handles parts up to 100 kg and dimensions of 400 x 400 x 400 mm or 500 x 280 x 400 mm. By adapting the arm design, this new upgrade maintains the original chamber volume and inert gas consumption. The SFM-AT350 solution now offers compatibility with 3D printers such as EOS M 400 and Nikon SLM® 500, making it suitable for medium-sized parts in additive manufacturing. According to the Solukon team, this improvement positions the SFM-AT350 as an optimal solution for complex components in industries such as aerospace and medical.

(Photo Credits: Solukon)

What do you think of the ocean conservation efforts by QOROX? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.