#3DExpress: Agnikul Cosmos Helps India to Reach for the Stars With 3D Printing

It’s that time once again! Now that Saturday is here, it is the moment to take a look back at some of the most pertinent news in the 3D printing news from the week. First, let’s start with Agnikul Cosmos. This Indian start-up has accomplished a world-first with the successful test launch of its semi-cryogenic engine that was 3D printed in one piece. Next, 3D Systems has announced that it has signed a major deal to make dental splints, a huge milestone for the leading 3D printer manufacturer. Next up, learn more about Asetek and its optimized cold plates made with AI and 3D printing before turning to the news that Elementum 3D has successfully registered a second pwoder with the Aluminum Association. Finish it off with SPEE3D, which has just launched its latest large metal 3D printer. Happy ready and have a great weekend!

Agnikul Cosmos Announces Successful Launch of Rocket With 3D Printed Engine

India continues to achieve different additive manufacturing milestones. This time, IIT Madras-incubated start-up Agnikul Cosmos, has announced a world-first. On May 30th at 7:15AM in India, the company successfully launched what they claim to be the world’s first rocket with a single piece 3D printed engine. Not only that, but the test, which took place on India’s first private launch pad, named ‘Dhanush,’ also marked India’s first semi-cryogenic engine-powered rocket launch. Discussing the success, Mr. Srinath Ravichandran, Co-Founder and CEO, Agnikul Cosmos, commented, “This is the culmination of 1000s of hours of reviews and hard work by the team. We are blessed to have had the opportunity and the full support of IN-SPACe and ISRO to design and build original space worthy hardware in India.”

Photo Credits: Agnikul Cosmos

3D Systems Signs a Major Agreement

Manufacturer of market-leading 3D printing solutions, 3D Systems announced this week that it has signed a 5-year, $250 million agreement, the largest since its creation. The agreement will enable the production of dental splints, a market in which the American company aims to gain a strong foothold over the coming years. Dr. Jeffrey Graves, CEO of 3D Systems, comments: “We believe the dental industry is now poised for a broad-based acceleration in the adoption of additive manufacturing technology that will impact all major dental applications, from tooth alignment and protection, to repair and replacement. With our decades-long leadership in the development of unique dental materials and printing technology, 3D Systems is ideally positioned to bring this full range of new, high-volume, custom applications to market over the next few years, and we are committed to do so.” In any case, this news has significantly boosted the company’s share price, and augurs a promising future for the manufacturer. Stay tuned!

Photo Credits: 3D Systems

Asetek Optimizes Cold Plates Through AI and 3D printing

Asetek is a Danish company dedicated to the design, development and marketing of liquid cooling solutions for computer systems. Now, they are using artificial intelligence and 3D printing in their cold plates to improve the efficiency of cooling systems. In adopting additive manufacturing, Asetek partnered with Fabric8Labs to create metal structures with innovative shapes impossible to achieve with traditional methods. With this new design, resistance to fluid flow is reduced, achieving effective cooling without the need for noisy pumps, maintaining system efficiency and making it quieter. Although Asetek has not specified when these products will begin production or how they will affect costs and production volumes, what is certain is that this synergy of technology has led to improved heat dissipation and hydrodynamic efficiency.

Photo Credits: Asetek

Elementum 3D Registers its Second AA Powder

The Aluminum Association (AA) is an organization that promotes global aluminum standards and sustainability. In addition to supporting the production of the material, it engages in sustainability research and provides information to policymakers and the public. This week, Elementum 3D announced that it has registered its second powder material, called A7050-RAM2, with the AA. Used with patented RAM technology, this material is an aerospace aluminum alloy for additive manufacturing that combines high toughness, strength and good stress corrosion tolerance. The Elementum 3D team adds, “For decades, AM enthusiasts have desired a wider selection of reliable, high-performance aluminum-based feedstocks for AM. We are honored to lead the advancement of metal AM alloy materials with the backing of the Aluminum Association.”

Photo Credits: Elementum 3D

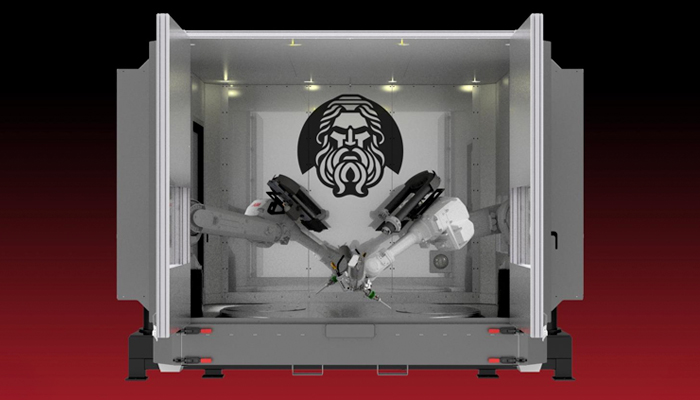

SPEE3D Launches New Large Metal 3D Printer

SPEE3D is continuing to grow. The Australian company has announced a new large-format metal 3D printer called “TitanSPEE3D,” which will use the company’s proprietary Cold Spray Additive Manufacturing (CSAM) technology and boasts an extremely large build volume of 2.4m diameter x 1m tall, with a printed part maximum weight of 2000 kg. It is compatible with various metals including 6061 Aluminium, Aluminium Bronze, and 316 Stainless Steel. “SPEE3D revolutionized large-scale metal 3D printing when we launched our first printer utilizing our unique Cold Spray Additive Manufacturing (CSAM) technology and have elevated this success through continual expansion of our 3D printing technologies,” further explained Paul Maloney, Chief Revenue Officer at SPEE3D. “The TitanSPEE3D will be a game changer for industries that rely on casting for very large parts, including defence, heavy industry, and others, to have the ability to print quickly, sustainably, and at a competitive cost. We’re thrilled to preview this technology at LSAAT.”

Photo Credits: SPEE3D

What do you think about the news from Agnikul Cosmos? Which country will be the next to go to the stars with 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.