#3DExpress: Aectual Announces its Own 3D Printed Wood

It’s time to take a look back at some of the news that has marked the additive manufacturing sector this week! We start this 3DExpress with a new development from Aectual: the company is now offering 3D-printed objects made from wood! The material is based on wood residues and natural ingredients, and is biodegradable and reusable. We continue the news with a surprising SLA machine, a solution featuring a conveyor belt in place of the traditional tray to boost productivity, before turning to Formlab’s new texture engine. Last but not least, we bring you 3D printed concrete water tanks by COBOD and Stratasys’ new acquisition of Arevo. Happy reading and have a great weekend!

Aectual Reveals 3D Printed Wood

Dutch architecture and interior design firm Aectual, known for its use of XL 3D printing of recycled waste materials, has launched a new product: 3D printed wood. As its name suggests, this new material is derived from wood-waste residue, blending natural ingredients like lignin and cellulose to mirror the composition, color and scent of wood. The best part? In line with Aectual’s mission to move towards a more circular economy, the material can absorb CO2, is fully biodegradable and can even be re-printed after use. The first use of the material so far has been for 1 x 2-meter wooden screens, to serve as wall paneling, room dividers, or window blinds.

Photo Credits: Aectual

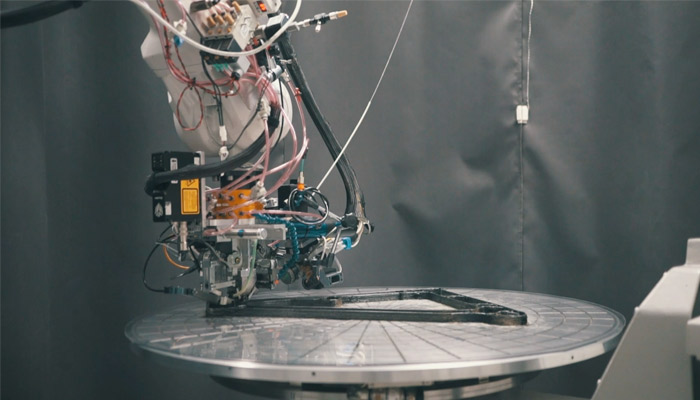

A Resin 3D Printer With a Conveyer Belt

We’ve seen FDM machines equipped with a conveyor belt instead of the traditional build plate to offer continuous printing and thus increase productivity. But a resin 3D printer? That’s the idea behind Israeli start-up Sprybuild, which has developed an SLA machine that combines speed and continuity of production thanks to its plate/conveyor belt. This has a speed of 3300 mm/hour, while the machine offers precision of 100 microns. The aim is to minimize operator intervention as much as possible, and make manufacturing as autonomous as possible. A start-up to keep an eye on!

Formlabs Announces Texture Engine for 3D Printing

One of the major reasons for post-processing in 3D printing is to change the surface texture and patterns in order to enhance the look and feel or optimize the part. Now, it is simpler than ever thanks to the recently launched Formlabs Texture Engine, currently available in beta form. With this, rather than turning to laser etching or by adding to the surface of a machined mold, users will be able to quickly make textured prints, which up until now has not been possible with even the most advanced CAD tools. An interesting development for users who wish to add texture for FDM, SLS or SLA 3D printing.

Photo Credits: Formlabs

3D Printed Water Tanks

In Kuwait, construction company Abyan used COBOD concrete 3D printers to design water tanks 4.5 meters high and 7 meters in diameter. Thanks to additive manufacturing, these structures use 25% less material and were designed in just 5 days. No reinforcement was used, the walls being reinforced with macrofibers. Abyan CEO Dr. Ahmad Al-Nassem added: “Abyan is wholeheartedly committed to revolutionising the construction industry at large by integrating cutting-edge 3D printing technology within concrete construction along with innovative solutions in design and construction materials, bringing forth a new era of efficiency and sustainability. So, when all of our calculations showed that with 0,95% macro fibers in the concrete, we could remove all hard reinforcement of the tank walls, we were keen to prove this new design concept with a real-life project.” These water tanks will be used by chicken farms.

Photo Credits: COBOD

Stratasys Continues to Grow

Additive manufacturing giant Stratasys has announced the acquisition of manufacturer Arevo, continuing its acquisitions and strengthening its portfolio of solutions. Arevo ceased operations in 2023, but was responsible for a number of promising innovations for the sector, notably in carbon fiber printing. Rich Garrity, Stratasys’ Chief Industrial Business Officer, commented: “The technology we’ve acquired allows for increasingly improved isotropy of physical properties in FDM parts, which opens up additional use for customers.”

Arevo developed a composite printing solution (photo credits: Arevo)

What do you think of this 3D printed wood from Aectual? Which news in this #3DExpress was the most exciting for you? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.