3DEO: Reinventing Low-cost Metal 3D Printing

3DEO are a unique new metal 3D printing company that are combining scalable aspects of traditional manufacturing, and applying them to 3D printing. Though they don’t currently sell their own 3D printers, 3DEO’s technology allows them to create parts at a lower cost than competitors, giving them an advantage. We spoke to Lance Kallman, 3DEO’s head of business development, about their technology, future plans, and more.

3DN: Introduce yourself, and tell us how you got involved in 3D printing!

My name is Lance Kallman and I lead business development for 3DEO. In my previous role, I was an executive recruiter at a large public firm and was focused on serving clients in the advanced manufacturing sector. Metal 3D printing is one of the most exciting technologies under the advanced manufacturing umbrella, and I was eager to join a team trying to lead this additive manufacturing revolution.

3DN: How did 3DEO get started in the 3D printing industry?

3DEO has three founders – two PhDs from the University of Southern California (USC) and an MBA grad from the University of California, Los Angeles (UCLA). Despite the school rivalry, they we able to come together for the shared vision of creating an affordable metal 3D printing technology. What began as an idea for a prototype, quickly became a functional technology and has now been commercialized. We are excited to be printing complex metal parts for our customers in production quantities.

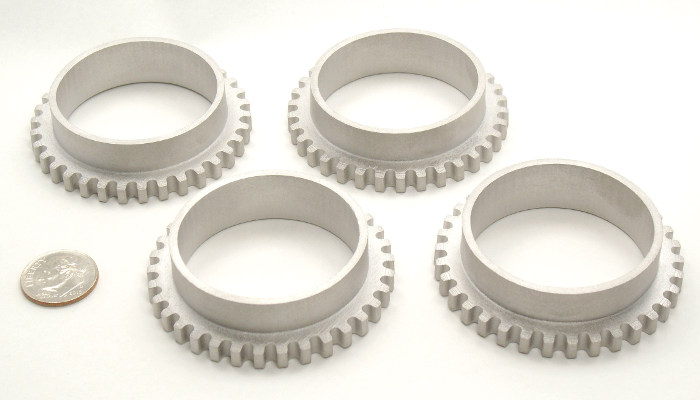

3D printed parts created using 3DEO’s metal 3D printing technology.

3DN: What does 3DEO do differently within metal 3D printing?

Since it’s inception, 3DEO has focused on lowering the final per-part-cost through a dual approach which includes 1) dramatically reducing the machine cost by taking sintering out of each machine and instead bulk sintering parts all at once and 2) using commodity powders that are up to an order of magnitude less expensive than the specialty powders used in other technologies. Our process is also highly repeatable because we do not use lasers that need constant attention or binder jetting inkjet heads which require costly maintenance — the result is that our first piece looks the same as our 10,000th piece, allowing for production volumes. From a quality perspective, we have tied ourselves to the existing metal injection molding standard, MPIF Standard 35, and work with customers that trust that standard today.

3DN: What are your current goals in metal 3D printing?

Our ultimate goal is to become the premier metal 3D printing parts supplier using our proprietary technology. We will achieve this by continuing to expand our capacity and serving every major industry that requires complex metal components. Though we do not sell the machines today, we can an envision a future where we eventually put our machines on the market.

3DEO’s technology can crate geometrically complex parts such as these.

3DN: What are your thoughts about the future of 3D printing, and what developments in the future do you find most exciting?

3D printing is becoming a key technology inside the Industry 4.0 factory of the future. I do not think metal 3D printing will be a one-stop-shop for every metal part manufactured anytime soon, but I do believe it will provide a critical manufacturing capability that every future factory will need. The per-part-cost will still be too high over the next 5-10 years for metal 3D printing to be considered for making parts that today can be stamped for under a dollar, but the technology is trending in that direction. I am most excited about the ability of 3D printing to democratize the manufacturing of metal parts and allow small and medium size businesses to compete with larger organizations. Leveling the playing field means more innovation and more competition, which is a win for the end consumer and for the industry.

You can visit 3DEO’s website here.

What do you think of 3DEO’s metal 3D printing technology? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!