3DCeram Transforms Productivity With Artificial Intelligence and Ceramic 3D Printing

3DCeram, a French manufacturer of ceramic 3D printing solutions, aims to support its users in additive manufacturing industrialization and mass-produced parts production. As experts in stereolithography, the team has developed a range of industrial machines that meet a variety of needs while focusing on precision, speed and large-format builds. This year at Formnext, the company unveiled CERIA, its brand-new artificial intelligence that is embedded in its 3D printers, which further optimizes additive manufacturing on an industrial scale. The AI can analyze both the print file and the manufacturing process in real time to reduce the risk of errors. To learn more about CERIA, 3DCeram’s ceramic 3D printers and post-processing solutions, we met Kareen Malsallez, the company’s Marketing Manager, and asked her all our questions.

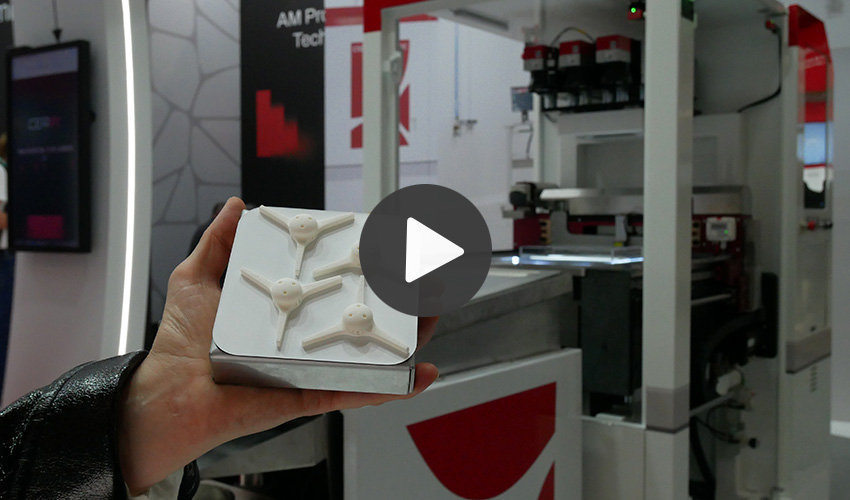

Today, 3DCeram’s product range enables technical ceramic part design in all possible configurations, from small to large production runs. Thanks to different plate sizes, the industrial machines offer diverse levels of productivity, a point that 3DCeram is emphasizing at this year’s Formnext. What’s more, the manufacturer is unveiling its CERIA artificial intelligence, integrated into its 3D printers, for the first time. CERIA is divided into two modules: CERIA Set, which analyzes the 3D file to anticipate printing errors and defects, and CERIA Live, which monitors the printing process live, adjusting layers if necessary.

Visit 3DCeram in Hall 11.1, stand D21 to find out more about the machines in the range, and to test the artificial intelligence in person!

What do you think of 3DCeram’s artificial intelligence solutions? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.