3D Systems announces enhancements to reverse engineering software

3D printing software is one of the key aspects of the additive manufacturing workflow. One which many engineers rely on when designing and optimizing parts. In recent years, multiple companies have been developing software tools that allow greater customization (through generative design for example) and part performance. 3D Systems, one of the leading 3D printing companies has also released an extensive suite of software to transform digital manufacturing workflows. Capabilities of its software suite include digitization and design to manufacturing, inspection and production management, amongst others.

In particular, 3D Systems announced new versions of its reverse engineering solutions, Geomagic Design X and Geomagic Wrap, which will enable to streamline workflows and empower designers and engineers with digital tools to achieve greater precision. By scanning a real-life object, data can be collected for reverse engineering applications – however some limitations still exist today. Therefore, the company stated that new features, including a unique unroll/reroll function in Geomagic Design X for complex revolved parts will result in a 94% efficiency improvement. Additionally, Geomagic Design X’s new features for hybrid surfacing workflows will accelerate productivity, and improve downstream CAD re-usability.

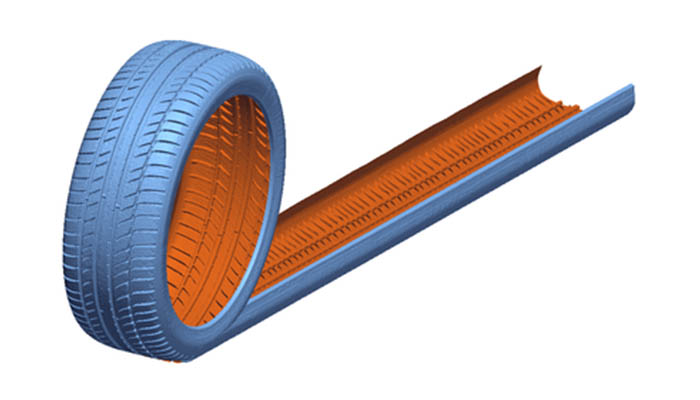

Unrolling of a 3D scan of a tire for mold modeling in Geomagic Design X | Credits: 3D Systems

Unroll/Reroll Function

3D Systems explains that revolved parts with features have historically been very cumbersome to model on CAD software. This is because CAD software uses a two-dimensional environment to create three-dimensional, rotating parts with multi-axis features. Therefore, the process often requires a great deal of trial-and re-work to get to a final part, which can lead to a lack of precision.

The newest Geomagic Design X release includes an Unroll/Reroll function that enables a new modeling workflow to tackle these complex, revolved parts. Using a comprehensive suite of mesh processing tools, an engineer can unroll the mesh to automatically extract a 2D sketch, make the modifications needed, and then reroll the sketch for additional engineering. This feature reduces the need for multiple rounds of trial and re-work.

Hybrid Surfacing

Additionally, topology optimized parts present unique challenges for repatriating a generative mesh, or 3D scan into CAD. The new Selective Surfacing features in Geomagic Design X 2020 simplify the hybrid modeling process, providing easy workflows for traditionally difficult parts with both organic and prismatic features. Selective Surfacing combines very fast organic surfacing with high precision feature modeling methods.

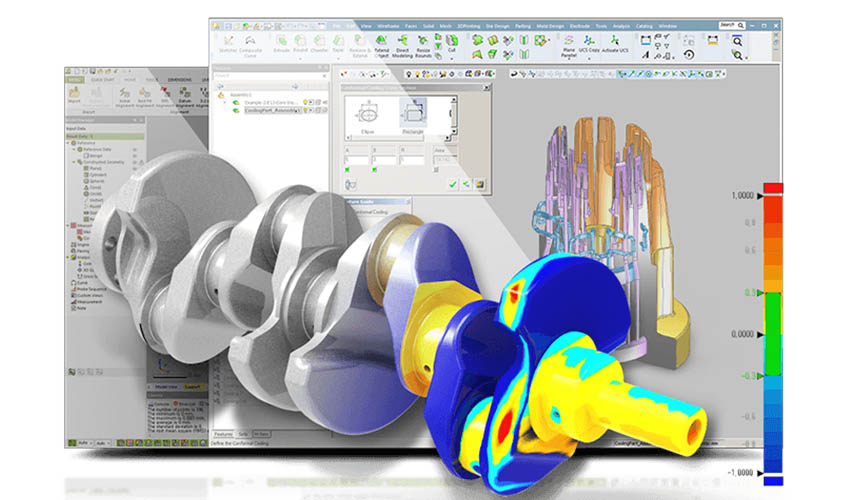

The GeoMagic software | Credits: 3D Systems

Geomagic Wrap reverse engineering software

As for Geomagic Wrap, the software transforms 3D scan data and imported files into 3D models for immediate use in downstream engineering applications across a variety of industries. In this new release, features include scripting automation and texture manipulation that accelerate designs.

These updates are expected to be released at the end of May 2020. You can find more information HERE. What do you think of these new features? Don’t hesitate to leave your thoughts in the comments below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter to receive all the latest news in 3D printing straight to your inbox!