3D Scanned, Tailor-Made Helmets for Motorcycle Racers

Can 3D scanning technology enhance the construction of helmets for motorcyclists? That question is being asked at the Prototyping Laboratory of the Miguel Hernández University Science Park (PCUMH) located in Elche, Spain. With advances in metrology and 3D scanning, this work is much easier. For the second consecutive year, the organization has renewed its collaboration agreement with MT Helmets, a brand dedicated to developing motorcycle equipment. Thanks to the implementation of 3D scanning solutions, teams in the Moto 2 and Moto 3-class competitions have managed to adapt the helmet models to the specific morphology of each rider, building custom helmets designed and adapted to each racer’s head.

New technologies are making ever greater advances in vehicle development. This is largely due to the advantages they offer in the creation of customized models with complex geometries. We can also find 3D printing in this area, which we have already seen being used for several automotive applications. In fact, many companies in the sector, such as Porsche, BMW or General Motors have already integrated additive manufacturing methods into their assembly lines. On this occasion, 3D scanning is the driving force behind the Moto 2 and Moto 3 research. The 3D scanning process allows accurate data to be obtained that will serve as the basis for the creation of customized helmets.

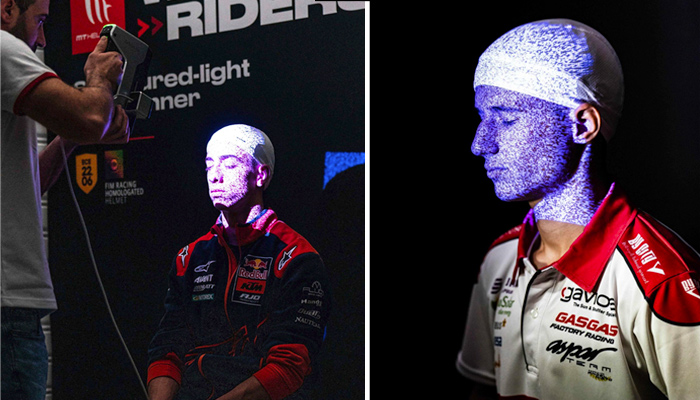

The process of 3D scanning the riders’ heads (Image credits: PCUMH)

This project all began when Álvaro Alhama, engineer and head of the PCUMH Prototyping Laboratory, moved to Cheste, the town where the motorcycling competition would take place. There, he carried out an entire digitization process thanks to an advanced 3D scanning solution based on white structured light technology. Once the scanning was complete, the data underwent a thorough digital polishing and cleaning process to ensure that the 3D model was an exact reproduction of the measurements and shape of the riders’ heads. MT Helmets later used these models to manufacture a special series of custom-designed helmets for each of the riders. The use of customized helmets has been reported to significantly reduce the vibrations experienced by competitors when reaching high speeds.

Álvaro points out that this improvement in ergonomics not only provides greater comfort for the riders but also increases their feeling of safety and focus on the track. Although only 3D scanning was used in this case, the benefit of tailor-made customization can also be found in technologies such as additive manufacturing. With the combination of PCUMH’s technical expertise and MT Helmets’ innovative vision, the foundations are being laid for the future of custom design and the successful application of 3D technology in a variety of industries. It now remains to be seen what other projects may emerge that make use of these new technologies on the racetrack and beyond. More information about this project is available in Spanish on the PCUMH website HERE.

The 3D head model after scanning. (Image credits: PCUMH)

What do you think about using 3D scanning to create custom helmets? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover photo credits: Motociclismo / Sport Life Ibérica