How to choose your 3D printing technology: Experts give their advice!

Whether you are a beginner or an expert in additive manufacturing, it is not easy to choose the right 3D printing technology. From Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS) or metal deposition, there is no shortage of choice. Each technology works with different materials and consequently will offer different results. So what should you consider when starting out in 3D printing? If you are wondering which 3D technology you should choose, continue reading as we interviewed three experts in additive manufacturing to guide your choice.

A bit more about our experts

We spoke to Artem Arno, the CEO at Treatstock, the e-commerce platform initially created in 2016 that provides 3D printing services for small to medium-sized businesses. Their aim has been to provide these SMBs with new sales leads by reaching out to worldwide markets using their platform. We also spoke to Ken Burns, the Technical Sales Director at Forecast 3D. Forecast 3D is the company that provides custom manufacturing and 3D printing services to a wide variety of industries including healthcare, automotive, aerospace, consumer goods and design. He told us that he partners with customers from all industries to bring their products from 2D to 3D. Last but not least, we spoke to Alec Richter, a Marketing Associate at MatterHackers, one of the largest 3D printing retailer in the US. His day-to-day activities include printing out assets using nearly every 3D printer carried by MatterHackers, troubleshooting the print settings or the printers themselves in order to make those assets, and occasionally answering technical questions about the harder to identify problems that can be experienced when 3D printing.

- Artem Arno, CEO at Treatstock

- Ken Burns, Technical Sales Director at Forecast 3D

- Alec Richter, Marketing Associate at MatterHackers

Firstly, are 3D technologies designed for different types of applications?

The first thing to consider when choosing your 3D technology is to determine what you are trying to achieve with it. Each technology has varied in popularity over the years, with new technologies debuting on the market quite regularly it can all get a bit confusing, Artem Arno explains, “All 3D printing technologies even the most innovative ones have their own limitations. That’s why there is no such thing as a one-for-all 3D printing process, that can be used for any application. Every project has their own requirements for the end part (for example, accuracy, strength, etc.)”.

In other words, each technology serves and thrives for several different industries. “HP’s Multi Jet Fusion (MJF) technology shines in automotive, healthare and industrial products” for example, explains Ken Burns. On the Treatstock website, a catalog exists: “For instance, if you choose the “Prototype” application you will see mostly services providing Fused Deposition Modelling. If you choose “Jewelry” you will see mostly services providing photopolymer 3D printing with castable types of resins”, we were told by Artem Arno.

3D printed mask of the Black Panther character from the Captain America: Civil War movie | Credits: Treatstock

Whereas some 3D technologies are designed for express purposes, it is not the case for all. For example, “Mcor 3D printers use paper and injet ink to create full color 3D prints, but since they’re made of paper and glue, they’re really great for low-cost demo models, not full use”, explains Alec Richter. He adds, “SLS printers work very well for usable parts, but the machines themselves aren’t cheap so you wouldn’t want to create something massive with an SLS machine if you don’t need to. Fused Deposition Modelling (FDM) 3D printers are relatively multi purpose, in that you can print something completely useless like desk toys or something you use on your assembly line every day, and have it be from a couple cents to a couple dollars of material”.

What about the materials?

Every 3D printing technology is typically designed to be used with a specific material (or group of materials). In other words, “If you know what material you need it is easier to understand which 3D printing process to use. Otherwise, I would suggest making a decision based on the application of the final product”, explains Artem Arno. However, Ken Burns told us that 3D technologies were not always developed for specific materials, “There are hardware components that can limit material capabilities but it doesn’t mean that the technologies cannot access more materials. There are many technologies that are open system and/or have developer kits that allow material developers to tune materials to the hardware”.

Credits: MatterHackers

As might seem intuitive, it is actually easier to develop a system to work with one material in mind rather than the reverse. “The material sets the specifications, and the 3D printer is built around it. Take metal for example, from the feedback I’ve gotten, it’s the Holy Grail for 3D printing; if you can affordably prototype using metal, you can cut out a significant portion of the prototyping process. But metal is hard to work with due to the high temperatures needed to melt it at best or sinter it at worst. The limitations of the metal mean that it can’t be extruded like an FDM printer, it needs a strong laser like and SLS printer, but even stronger than that, that’s why DMLS (Direct Metal Laser Sintering) printers are so expensive”, explains Alec Richter.

And what technology and machine do our experts choose for their projects? Is the price important to them?

Alec Richter said, “I’m in an office environment, so I almost exclusively use FDM 3D printers with the occasional (I’m talking once a quarter) use of an SLA 3D printer. For most people, FDM 3D printers can handle plenty of different use cases, and the price is one of the biggest factors. Across almost every type of 3D printing, the material cost for FDM (plastics) is low and is readily available from a variety of sources. Of course price makes it easy to use, but having it right next to my desk makes it a lot easier to design, iterate, and reprint than if it were in a machine shop in the next building”.

Credits: Forecast 3D

For our expert at Treatstock, Artem Arno, the choice of technology and machine always depends on the 3D print someone is trying to achieve: “If I need to 3D print something I would ask myself a whole series of questions: What is the application of the 3D print? Is it a fully functional prototype or just a demonstrative model? How accurate must it be? In what conditions will it be used? And so on and so forth”.

Ken Burns comments, “Yes, price is certainly a consideration but the quality and speed are typically competing for importance. It is really more about the machine capabilities and what industries/applications we want to focus on with them”.

Finally, what are your recommendations for a complete beginner? What are the criteria to consider?

“If you are a total beginner in the world of 3D printing you should determine at least two main parameters: 1) the budget of your project 2) application of the 3D print”, suggested Artem Arno. Also, “Every 3D printing process can be tricky for the total beginner but FDM, SLA, DLP and technologies alike might be the best options for the inexperienced user”.

For our expert at Forecast 3D, he agrees that there are now many options for begineers on the market, “We have seen a lot of new printers come into the marketplace that have really positioned themselves around simplicity. Even many of the larger 3D OEMs have made equipment that allows for faster adoption. Before making a recommendation it is better to understand what one might need while starting out. For example, there are a lot of great beginner printers on the market but some of them are very limited by software solutions for them. If you are software savvy then this might be a great printer to start with. If not, it could prove to be very challenging”.

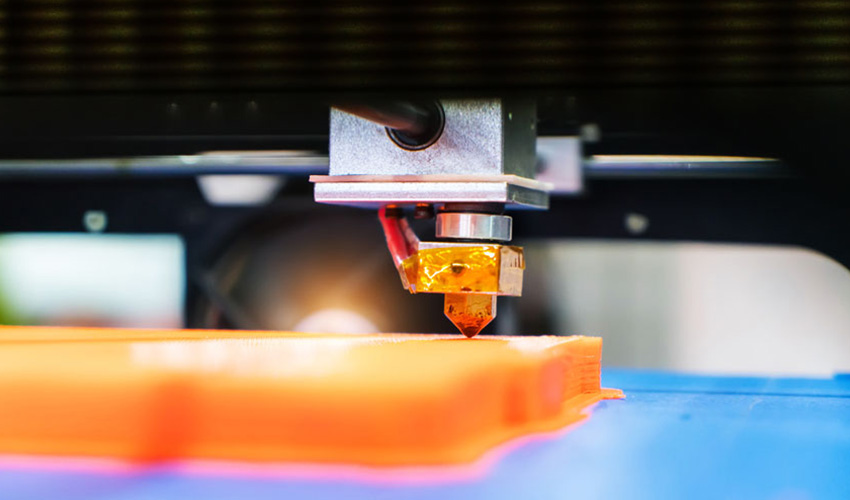

The FDM technology is recommended for complete beginners

For Alec Richter, a complete beginner should go for an FDM machine, “It’s the most accessible, it has the largest pool of other users. FDM 3D printers are, when you get down to it, really simple, they’re a precise hot glue gun strapped to a couple motors”. He adds, “For me, the most important thing to consider when choosing a 3D technology for the first time is to be real with your budget and understand when what you want doesn’t fit within your price range. If you have a budget of $500, don’t expect the printer to do all the same things as a $2,500 printer”. In other words, you cannot expect things like a sensor to detect when your filament has run out and pausing the print until you reload material, or dual extrusion for multiple materials or colours on any sort of small-budget printer.

If you need more information about each technology, we have our guides HERE. Find more information from each of the experts on Treatstock, Forecast 3D and MatterHackers websites.

Did you find the advice from our experts useful? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!