3D Printing Revolutionizes Drug Delivery With Personalized Tablets

Researchers at the University of Nottingham’s Centre for Additive Manufacturing have achieved a significant breakthrough in personalized healthcare through a novel 3D printing technology known as multi-material inkjet 3D printing (MM-IJ3DP). This achievement will allow for the creation of tablets containing multiple drugs, each released at specific times. This advancement, led by Dr. Yinfeng He from the Centre for Additive Manufacturing and Professor Felicity Rose from the School of Pharmacy, promises to revolutionize the pharmaceutical landscape by enabling the creation of highly customized drug delivery systems with unparalleled precision, resulting in improvements in how medication is managed and administered.

This innovation is centered around poly-ACMO, a new soluble polymer ink specifically formulated for pharmaceutical applications. This unique material, composed of light-sensitive molecules, solidifies when exposed to ultraviolet light, creating its water-soluble framework within the tablet. Scientists have successfully leveraged 3D printing to harness poly-ACMO’s unique properties and engineer tablets with tailored drug release rates and spatial distribution. This paves the way for unprecedented levels of treatment customization, allowing doctors to address the specific needs of each patient more effectively and administer medication at a more controlled rate.

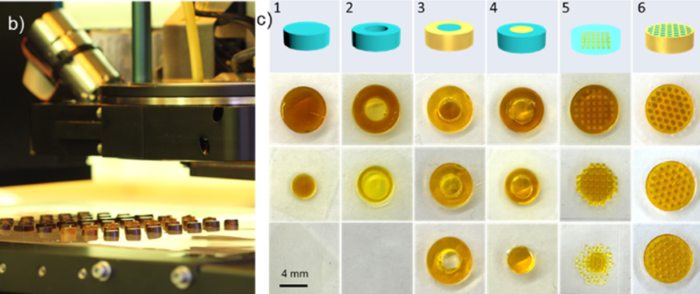

The designs of tablets printed by MM-IJ3DP technology.

This approach offers additional benefits. The tablet’s unique interior structure not only controls the drug release rate for more accurate timing but also enables the printing of multiple drugs within a single tablet, simplifying complex medication regimens into one dose. This technology is especially advantageous for patients with intricate medication schedules. Traditionally, managing multiple medications can be confusing and difficult, requiring patients to take several pills at different times throughout the day. MM-IJ3DP simplifies this process by combining multiple drugs into a single tablet, designed to release each component at the appropriate time.

Speaking on these benefits, Dr. Yinfeng He, Assistant Professor in the Faculty of Engineering’s Centre for Additive Manufacturing, stated, “This is an exciting step forward in developing personalized medication. This breakthrough not only highlights the potential of 3D printing in revolutionizing drug delivery but also opens up new avenues for the development of next-generation personalized medicines.”

While the potential of MM-IJ3DP is immense, there are still challenges to overcome. The current focus is on developing more ink formulations to accommodate a broader range of medications. Fortunately, the research team is confident that the application of this technology will rapidly expand and improve. As of now, MM-IJ3DP allows for up to 56 different medications to be printed simultaneously. Its ability to create individualized pharmaceutical solutions may likely drive forward a new era in healthcare, where treatments are as unique as the patients they serve. Echoing this sentiment, Felicity Rose, a Professor at the University of Nottingham’s School of Pharmacy, added:

The future of prescribed medication lies in a personalized approach, and we know that up to 50% of people in the UK alone don’t take their medicines correctly and this has an impact on poorer health outcomes with conditions not being controlled or properly treated. A single pill approach would simplify taking multiple medications at different times, and this research is an exciting step towards that.”

What do you think about MM-IJ3DP’s ability to enhance personalized healthcare? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: University of Nottingham