3D Printing Personalized Medicines with goatAM

Reinventing 3D printing for the pharmaceutical sector — that’s the ambition behind goatAM. Drawing on their research expertise, the company’s founders are developing solutions for the production of personalized medicines, including 3D-printed pills. With this innovative approach, goatAM aims to transform access to tailored treatments, put patients at the center of care, and help democratize 3D printing. We spoke with the startup to learn more about its vision, technologies, and the challenges of 3D printing medicines.

3DN: Can you introduce yourselves and tell us about your journey into 3D printing and the creation of goatAM?

We are Tilmann Spitz (CEO and founder) and Fabian Loose (CTO and founder) of goatAM. Both mechanical engineers trained at the Technical University of Cologne, we carried out research within the university’s Production Systems Laboratory. It was there that we discovered 3D printing and began developing specialized systems and techniques, mainly for industrial applications. Our work included 6-axis 3D printers, large-format polymer foam printing, and AI-assisted analysis tools for plastics processing.

The goatAM team. Left: Fabian Loose; right: Tilmann Spitz. (Photo credit : goatAm)

goatAM was founded following the completion of several university projects. In 2018, Heinrich Heine University in Düsseldorf approached us to explore 3D printing for personalized medicines. Although our expertise at the time was rooted in mechanical engineering, we quickly became fascinated by the topic. Two projects emerged from this collaboration: one focused on 3D printing single-dose pills using a screw extruder for centralized production, and the other on an FDM-based approach for decentralized manufacturing in pharmacies. The success of the second project, carried out with Heinrich Heine University and Merck KGaA, attracted significant interest and ultimately led to the creation of goatAM and the commercialization of our technology.

3DN: What 3D printing technology and materials do you use for 3D-printed pills?

The 3D printing of personalized medicines relies on a range of technologies, from material jetting and DMLS to FDM and SLS. Unlike conventional FDM machines that use continuous filament spools, we have developed specialized cartridges where the materials, already mixed with the active ingredient, are stored and directly integrated into the printing process.

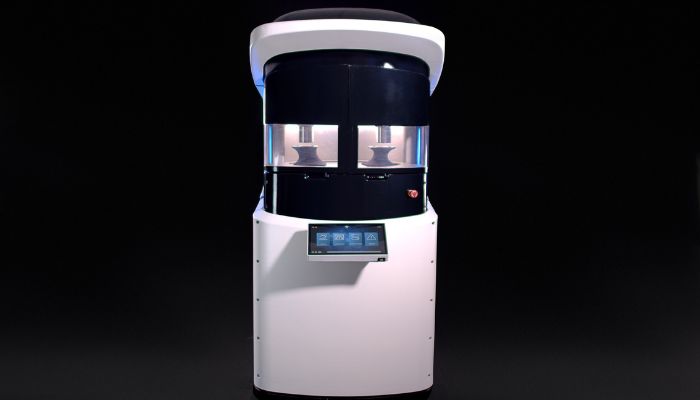

The company’s 3D pill printer (Photo credit: goatAM)

These materials are produced using a pharmaceutical screw extruder, similar to how common polymers like ABS or PLA are processed. However, the polymers we use are specifically engineered to be mixed with active substances and metabolized by the body. Each one is carefully selected to prevent any adverse reactions with the active ingredient. A commonly used example in research is Evonik’s Eudragit, although it is not compatible with all active substances.

As part of a project conducted with the Technical University of Cologne, Heinrich Heine University in Düsseldorf, and Merck, the latter developed an innovative polymer compatible with a wide range of active ingredients. Since some compounds cannot be converted into solid form, we have expanded our system to include semi-solids, further broadening the diversity of substances that can be processed.

3DN: What are the advantages of your 3D pill printer, and who can use 3D-printed pills?

3D-printed pills offer significant advantages over conventional tablets. They enable precise dosing without altering the material and provide targeted control over the release of the active ingredient. By adjusting the surface-to-volume ratio, the absorption rate can be fine-tuned, as a larger surface area releases more of the substance at once. It is also possible to combine multiple active ingredients in a single pill, reducing the number of tablets a patient needs to take. This innovation is particularly beneficial for older patients, improving both comfort and adherence to treatment.

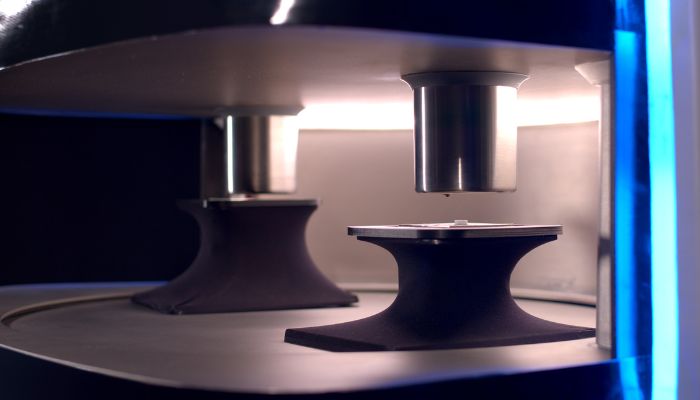

Our printing system stands out for its ability to be used directly at the point of care, such as in hospitals or pharmacies. To achieve this, we developed an optimized cleaning process that minimizes downtime during material changes, making integration into pharmacies more cost-effective. In addition, our printer features a unique AI-based quality control system. With the help of multiple sensors, we can evaluate in real time whether each tablet meets the required specifications. If not, the printing parameters are automatically adjusted to ensure the final product meets quality standards.

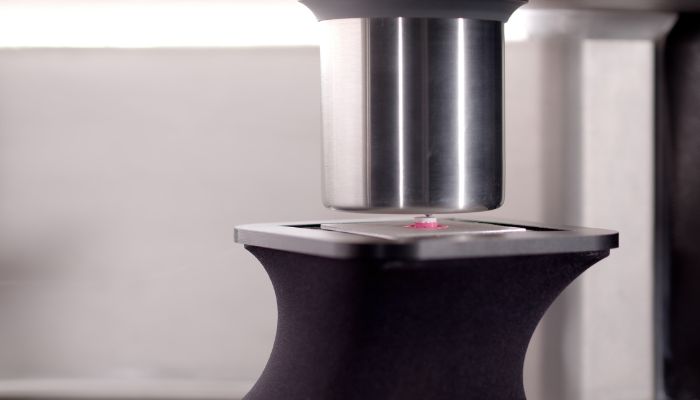

3D printing of a pill. (Photo credit: goatAM)

There is still a way to go before our printing systems are deployed on a large scale in pharmacies. In the short term, they will be used for drug development, clinical trials, and hospital settings. Their applications in pediatrics and oncology are especially promising. In children, metabolism changes rapidly, making the flexible production of small, personalized batches essential. In oncology, even slight variations in dosage can have a major impact on treatment effectiveness and recovery outcomes.

3DN: What are you currently working on, and what have been your most exciting projects so far?

We currently have a prototype whose performance has been validated in the lab. Our focus now is on transforming it into a market-ready product, reducing its size to create a desktop device, and optimizing its usability so it can be seamlessly integrated into the daily routines of pharmacists and technicians. On the design side, we are refining the subassemblies to enable cost-effective series production. At the same time, we are developing our marketing and distribution strategy while identifying customers to test and further improve our systems. Finally, we are collaborating with new partners and suppliers, particularly those developing filaments containing active ingredients, with the goal of expanding our range of 3D-printed medicines in the future.

(Photo credit: goatAM)

We had the opportunity to be part of a consortium with Heinrich Heine University in Düsseldorf and Merck KGaA as part of a research project funded by the Federal Ministry of Education and Research. This collaboration allowed us to cover almost the entire production chain. While Merck developed specialized polymers for pharmaceutical 3D printing and Heinrich Heine University integrated the active ingredients into these polymers, our team focused on developing the printer capable of processing them. This setup enabled us to perfectly coordinate each stage of the process.

We are also currently taking part in several working groups exploring how to assess the value of a 3D-printed tablet. Given the many advantages of this technology compared to traditional manufacturing methods, these benefits need to be reflected in a cost model. For example, savings in recovery time or the reduction of secondary treatments caused by side effects could justify a higher unit price for such tablets.

3DN: What are the main challenges of 3D printing pills, and how do you hope to improve the healthcare system with your 3D printer?

Our efforts have primarily focused on three key areas: the requirements related to the active ingredient, the ease of cleaning the machine, and quality control. In conventional 3D printing, it is well known that each material comes with its own challenges. In our case, it is crucial to carefully control the temperatures to which the active agent is exposed and the duration it remains in a molten state to prevent any degradation.

Cleaning the system is just as essential. There must be no traces of active substance left from previous production runs. The cleaning process therefore needs to be both thorough and efficient, which has been a significant challenge to solve. Finally, it is vital to ensure that each tablet contains the precise amount of active ingredient. To achieve this, we have integrated a range of sensors, including weighing cells, that automatically adjust the process parameters to ensure every tablet meets the required specifications.

(Photo credit: goatAM)

Personalized medicine undoubtedly represents the future of patient care. Some major pharmaceutical companies even predict that by 2030, all new therapies will be designed to be individualized. However, these therapies, no matter how effective, can only deliver real benefits if they can be distributed cost-effectively. Current production systems, designed to manufacture hundreds of thousands of tablets at once, are not suited to individualization. Currently, the only alternative is to manufacture drugs manually, a costly method that is difficult to deploy on a large scale due to a lack of qualified personnel.

Our 3D printing system provides a clear solution: simple and cost-efficient production of medicines, directly where they are needed. We see our technology as a true gateway, a tool that doctors, pharmacists, and technicians can use to develop new therapies and provide every patient with the personalized care they deserve.

3DN: Do you have any final thoughts to share with our readers about goatAM’s long-term goals?

As mentioned earlier, we are currently optimizing our prototype to turn it into a market-ready product, with the goal of completing this phase within a year. We plan to bring it to market within 18 months, starting with a rollout in Europe while keeping a close eye on global markets, particularly the United States and Asia, which are key strategic targets. In the beginning, the system will primarily be used by research institutes, pharmaceutical companies, and hospital pharmacies.

Within about five years, we hope to see adoption in compounding and community pharmacies. By that time, we plan to release a second version of the system and explore additional areas of application, such as personalized dietary supplements and traditional medicine in Asia, both of which represent highly promising markets.

In the future, goatAM also hopes to conquer the Asian and American markets. (Photo credit: goatAm)

Our dream is to one day make personalized treatments available to every patient through 3D-printed tablets. In this future, our printing system would be accessible in local pharmacies. When feeling unwell, patients would visit their doctor, who could analyze their metabolism using a simple test. The doctor would then prescribe the appropriate medication and dosage. Patients could take this prescription to the pharmacy of their choice, where the pharmacist would insert the necessary materials into the printer, upload the prescription data, and start the printing process. Just a few minutes later, the medicine would be ready for pickup. Ideally, patients would be able to leave with their personalized tablets immediately after their consultation. To make this vision a reality, we are not only developing 3D printers but also collaborating with pharmaceutical companies to supply the required materials and support pharmacies in developing personalized formulations.

Unfortunately, the pharmaceutical sector remains highly conservative, which often creates obstacles, especially when introducing new technologies and production methods. Moreover, hardware development is a long and complex process. Our main priority right now is to find investors and partners who are ready to join us on this journey. We are particularly looking for visionaries interested in applying our technology to other fields, such as veterinary medicine or the production of active implants. We hope to complete our fundraising soon so we can focus entirely on development and commercial launch. To learn more about goatAM, click HERE.

What do you think of goatAM’s customized 3D printing of pills? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel. Interested in more medical and dental 3D printing news? Visit our dedicated page HERE.

*Cover photo credits: goatAM

I like this post!!