How is 3D Printing Used in the Nuclear Power Sector?

One of the sectors where additive manufacturing has had an increasing role in recent years is energy. Already, we have told you about the many applications for 3D printing in Oil & Gas, but did you know that it is also being used for nuclear applications? The nuclear power plant industry has been gaining in prominence in recent years with data from the World Nuclear Association showing that in 2019 it was the world’s second largest source of low-carbon power with 438 operable reactors spread across 33 countries. Moreover, in 2020, the total world nuclear electricity generation was 2,591 billion kWh, or 10.1% of the total world electrical generation according to the U.S. Energy Information Administration (EIA). Given this rise in popularity, it makes sense as well that the sector is also turning to new technologies, including additive manufacturing. To better understand how exactly it is being used, we took a closer look at some of the top uses of 3D printing in nuclear power plants in no particular order.

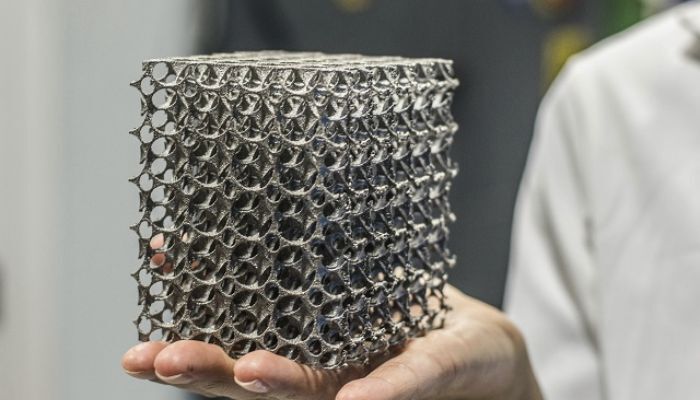

A 3D Printed Reactor By ORNL

One of the most active players in the nuclear and 3D printing field is undoubtedly the Oak Ridge National Laboratory (ORNL) in the United States. Its teams have been working for several years on how additive manufacturing can influence the way we think about nuclear power. In May 2020, for example, they presented the first prototype of a reactor core, printed in 3D metal via a DED machine. This project is part of the “Transformational Challenge Reactor Demonstration” (TCR) program, whose objective is to imagine energy systems that are less expensive and more productive, all within a very short timeframe. In fact, this reactor core was created in only three months, from the design phase to post-processing; the printing process required 40 hours of work, at temperatures reaching 1,400°C. You can watch the accelerated 3D printing in the video below:

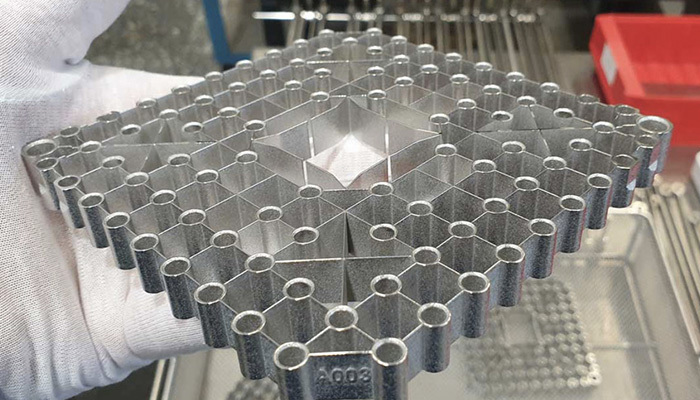

Ultra Safe Nuclear Corporation in Collaboration with ORNL For Micro Reactors

Ultra Safe Nuclear Corporation is a US nuclear firm which aims to develop and vertically integrate safe, clean, and commercially competitive nuclear solutions. In 2022 it announced plans to collaborate with Oak Ridge National Laboratory to use the latter’s additive manufacturing capabilities to advance nuclear power, by using Binder Jetting in order to make micro modular reactors. The choice of additive manufacturing allows the team to overcome the difficulties associated with working with silicon carbide, a technical ceramic; they will save money and be able to design more complex geometries than with conventional methods. Find out more HERE.

Photo credit: USNC

Czech Energy Firm Uses 3D Printing to Optimize Supply Chain

ČEZ is a utility company and the largest public enterprise in Central and Eastern Europe. The company’s nuclear division, which works with Czech nuclear company Škoda JS, has turned to additive manufacturing to optimize its own supply chain and reduce downtime. This year alone, they have produced 4159 plastic and metal parts using this technology.After the Corona pandemic and the war in Ukraine exacerbated the geopolitical situation, triggering significant supply chain problems, the company turned to additive manufacturing. A large-scale printer can produce metal parts weighing up to 600 kg, allowing defective parts to be replaced in a short time. Bohdan Zronek, a member of ČEZ’s board of directors and director of the nuclear energy division, explained that geometrically simpler parts are produced using conventional methods, while 3D printing is particularly suitable for complex parts such as a gearwheel.

In addition to plastic, metal 3D printing has been the preferred method of nuclear companies (Image: Markforged)

Safety Critical Components in an Alabaman Reactor

In the United States, there are currently 93 operating Nuclear Power Plants according to data from EIA. One of these is the Tennessee Valley Authority’s Browns Ferry Nuclear Plant located in Athens, Alabama, the second most powerful nuclear plant in the country. What is particularly interesting for us is that it is there, in Plant Unit 2 more specifically, that the TVA, Framatome and the DOE Office of Nuclear Energy–funded Transformational Challenge Reactor, or TCR, program based at Oak Ridge National Laboratory (ORNL) installed four 3D printed fuel assembly brackets for use in a nuclear reactor back in 2021. The project was an interesting one because it was the first of its kind in the country and showed that it was possible to deploy qualified 3D printed components in highly regulated environments, like nuclear reactors. The safety fasteners, which are safety critical components, were made using laser powder bed fusion and TruForm 316 (Fe-271), a metal powder alloy which consists of iron, Nickel, chromium and molybdenum. 3D printing was chosen as a way to help make the fasteners’ non-symmetric geometry.

Siemens in Slovenia: the Krško Plant

The first 3D printed and operational part in a nuclear power plant was the work of Siemens. It is a 108-mm-diameter metal impeller of a fire pump constantly in operation at the Krško nuclear power plant in Slovenia, designed and additively manufactured by Siemens. The use of additive manufacturing was essential, as the original impeller had been in operation since the plant was commissioned in 1981 and its original manufacturer is no longer in business. The Siemens team in Slovenia then reverse engineered and created a “digital twin” of the part to use Metal Additive Manufacturing to recreate the part.

The project marked an important step forward for the AM industry, as for the first time a 3D printed part demonstrated safe operation and passed all the tests required for nuclear power, one of the most complex and demanding industries.

Photo credit: Siemens

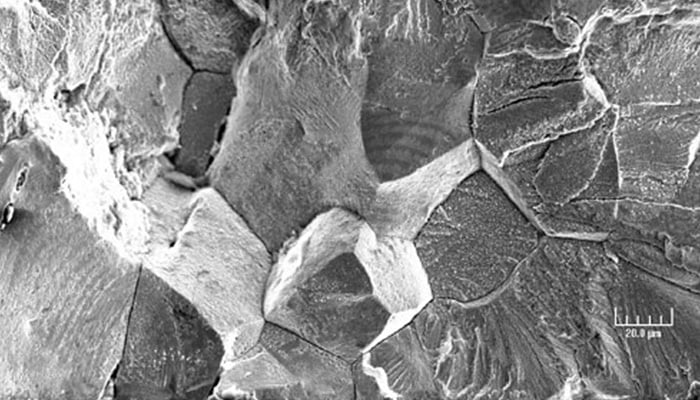

The University of North Dakota Develops Nuclear Reactors

A group of researchers at the University of North Dakota have created a project to develop 3D printed nuclear reactors with reinforced steel. To manufacture these components Roy Sougata (professor of mechanical engineering) and his team will use austenitic steel: this metal alloy is reinforced with nitrogen and will be the main raw material in the construction process. At the moment, no information has been provided about the 3D printer used and the main idea is to see if these 3D printed components are more efficient than those designed in the traditional way. The design of the parts will be carried out at the University of North Dakota while further analysis will be performed at Oak Ridge National Laboratory (ORNL). In addition, testing of the components will focus on their tribological properties (the science of wear, friction and lubrication) at high temperatures.

Austenitic steel will be used as the main material (Photo credits: Dr. K. Natesan)

Westinghouse Electric Company Forges Industry Firsts with 3D Printing

3D printing plays an important role in the making of functional parts. In 2020, Westinghouse installed a thimble plugging device in one of its nuclear reactors, made using 3D printing. At the time, this was a first in the industry. It continued the additive manufacturing focus, and two years later broke new ground once again with the installation of a 3D printed debris filter, the StrongHold AM, in two Boiling Water Reactor (BWR) units in Finland and Sweden respectively. These filters offer enhanced capture features and represent a step forward for the firm in the adoption of additive manufacturing. You can find more information HERE.

Photo credits: Westinghouse

3D Printing for French Nuclear Firm Framatome

The French multinational Framatome has announced that it has developed a 3D printed stainless steel fuel assembly component. This product was manufactured at a nuclear power plant in Forsmark, Sweden, specifically at Vattenfall. This is a first for the French company, which successfully installed the component. The part is a top end grid to hold the fuel rods, metal tubes in which cylindrical pellets of sintered uranium dioxide are stacked. It was also made to prevent bulky debris from going into the fuel assembly. To produce it, a 3D laser printing technology was used, but Framatome did not mention which one precisely.

Photo credits: Framatome

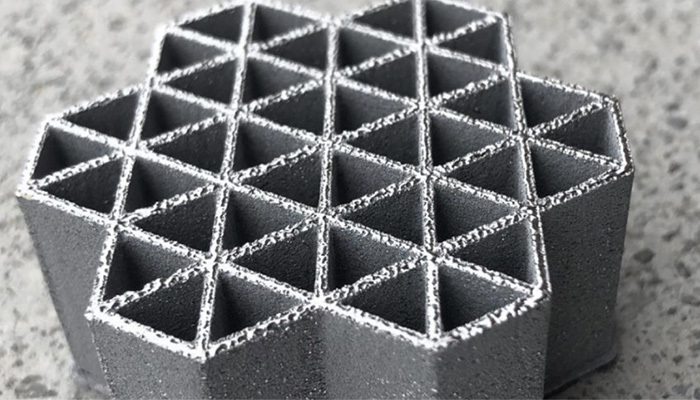

3D Printed Microreactor From Purdue University

Purdue University, Indiana (USA), has received an $800,000 grant from the U.S. Department of Energy to participate in the creation of a 3D printed microreactor. The university will participate in the Transformational Challenge Reactor Demonstration Program, in which the Department of Energy’s Oak Ridge National Laboratory is working to create the first 3D printed microreactor by 2023.

The Purdue team’s mission will be to develop artificial intelligence technology to ensure the quality of additively manufactured nuclear reactor components. Indeed, the combination of additive manufacturing and artificial intelligence techniques allows for a more data-rich and cost-effective nuclear component qualification process. In detail, Purdue University’s solution will apply reinforcement learning, a kind of artificial intelligence that uses advanced machine learning strategies to fine-tune the selection of optimal AM process parameters, such as printing speed and melting temperature, to train artificial intelligence models and guide the decision-making process making it more efficient and faster.

3D printed components of the nuclear reactor. (Photo credits: ORNL)

BWX Technologies Collaborates with ORNL

BWX Technologies and Oak Ridge National Laboratory (ORNL) are working on a metal 3D printing technology for the manufacture of nuclear components. With the goal of powering a nuclear reactor, the two partners aim to produce parts from high-temperature alloys based on nickel and refractory metals. BWX Technologies would have used an electron beam melting system to 3D print the parts. According to the company, the choice of these materials allowed researchers to increase the components’ resistance to temperatures up to 1,482°C, and to achieve overall plant efficiencies of about 50 percent. Additive manufacturing also reduces costs, particularly in terms of part maintenance and repair, but also speeds up the component prototyping stage.

Photo credits: Oak Ridge National Laboratory

What do you think of these companies using 3D printing for nuclear power? Did we miss any examples? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Nicolas HIPPERT on Unsplash