How 3D Printing Will Change Manufacturing

3D printing is a special type of digital fabrication called additive manufacturing. The difference between additive manufacturing and traditional techniques is that objects are created layer-by-layer, so there is minimal loss of material. This creates a potential for a more efficient production process with minimal waste, and less harm to the environment.

Manufacturing reinvented

3D printing is constantly changing the way we think about manufacturing. Let’s consider some facts and trends. In 2005, when the patent to a 3D printing technology called Fused Deposition Modeling expired and became available to the public, many engineers and hobbyists noticed huge potential in additive manufacturing. Why? This is because the components of a simple FDM 3D printer were not expensive. The machine itself was the same as a standard size desktop and prints plastic.

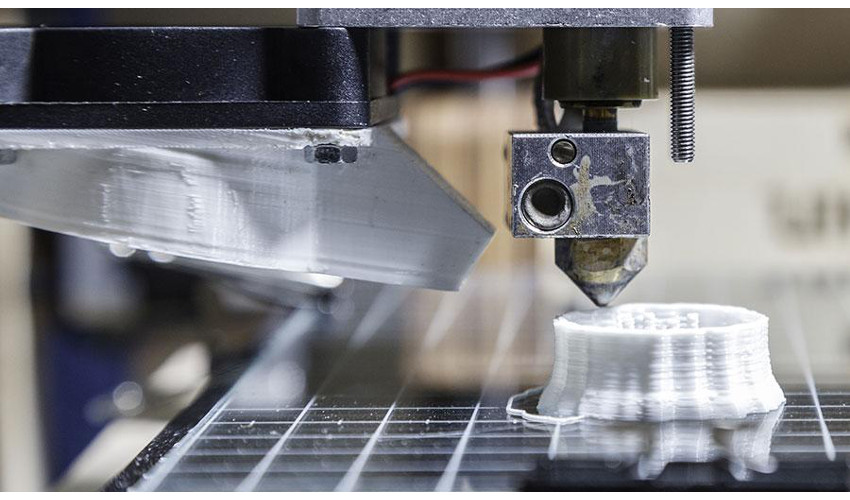

Today’s 3D printers, like Zortrax M200 or Zortrax M300, are reshaping manufacturing. 3D printing is more affordable, FDM machines can be used in every workshop and stand on the user’s desktop. Moreover, almost everyone can become a maker. Nowadays, creating prototypes does not require bulky CNC machines, we have 3D printers!

Zortrax 3D printers are reshaping manufacturing.

Speed of 3D printing

Unfortunately, 3D printers cannot compete with standard CNC machines in speed. Mass production is still out of range of FDM 3D printing. Nevertheless, many producers are trying to make 3D printing more effective and less time consuming. There are two main approaches here.

The first solution is strictly connected with the technology of 3D printing. Manufacturers are developing new machines like photo polymerization-based 3D printers that use special resins and UV light to form layers of an object. Such printers have only one axis (vertical) and a whole layer is created in one time during UV curing. This process is faster because the layer is 3D printed in a short period of time.

The second approach is a 3D printing cluster. Clusters or cells are designed to quicken the process of mass production and they incorporate a large number of working 3D printers. Nowadays clusters are fully automated and manufacturing is uninterrupted. There is a strong belief that such a solution may affect fabrication when it comes to mass production.

Some printer brands, such as Stratasys, HP and Renishaw, are aiming to make 3D printing a viable mass production option.

3D Printing: The next level

3D printers can be taken to the next level – high in the Earth’s orbit. This is something that is happening in front of us. In terms of manufacturing, the main goal is to achieve functional and ready-to-use products. 3D printing on the International Space Station in zero-gravity environment to some may sound exotic, but additive manufacturing can be performed in that rough conditions.

How this is helpful? If we can transform manufacturing technologies so they can serve on board the ISS, using special 3D printers and digital files to produce parts, tools and replacements on-site in the very moment they are most needed, we could lower mission costs. Bearing this in mind, the concept of self-repairing or even self-replicating spacecraft may come to life some day.

Near future

There is no doubt that 3D printing will change manufacturing. In fact, it is already happening. As new 3D printing technologies are being created, more and more people will use desktop 3D printers. Referring to the Wohlers Report, the 3D printing industry will almost triple its value – from $7bn in 2016 to over $21bn in 2020. This will be a very interesting time for all of us interested in additive manufacturing.

What do you think of 4D printing? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!