3D Knitwear: How 3D Printing Is Revolutionizing the Fashion Industry

In recent years, 3D printing has become growingly everpresent. From medicine, aerospace, to design, and construction — every day there’s news about breakthroughs, innovations, and developments in the additive manufacturing industry. However, in one particular industry, it’s still pretty quiet regarding developments around 3D printing. We’re talking about the fashion industry. It cannot be denied that the first experiments and advances in 3D printed clothing have only been recorded relatively recently. Yet, if you have followed these developments in fashion a little more closely, you may have noticed that these are high-end fashion, i.e. clothing created for the runways and red carpet and not for everyday wear. The reason why the combination of 3D printing and clothing seems so difficult is quite simple: The materials used in 3D printing, mostly plastic, and metal, are not flexible enough. To counteract this problem, some fashion and 3D enthusiasts have been looking into suitable options and ultimately honed in on one solution: 3D knitwear. But, what exactly is 3D knitwear? How does its production method differ from additive manufacturing and conventional textile production? Will 3D knitwear be available as ready-to-wear for ordinary consumers in the near future? We got to the bottom of this topic in more detail and we clarify all of these questions with the help of various expert opinions from the industry.

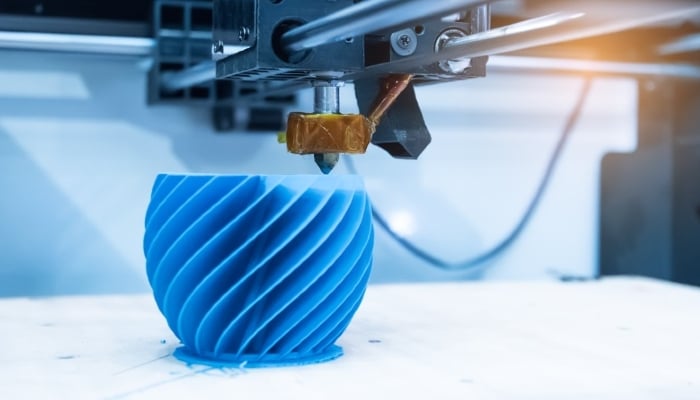

In order to understand the principle of 3D knitwear and its differences and similarities to 3D printing, it is first necessary to take a look at the definitions. Gihan Amarasiriwardena, co-founder and CEO of the Ministry of Supply, defines 3D printing as follows: “In 3D printing, molded products (such as plastics) are produced by adding a layer of material (often plastic or synthetic) according to a given digital Design is ‘printed’.” Rosanne van der Meer, designer and founder of New Industrial Order, offers a broader definition: “3D printing is the production of a three-dimensional shape on the basis of a filament that is formed by a machine.“ In fact, 3D printing is all about computer-controlled machines creating three-dimensional objects and building them up layer by layer. The question now remains whether 3D knitwear is made according to the same principle.

In 3D printing, the object is additively manufactured layer by layer.

Production of 3D Knitwear

The manufacturing process of 3D knitted fabrics is quite similar to other 3D objects. Both begin on a computer: CAD software is used to create the design and ultimately to obtain a programming language. The digital codes are then forwarded to the machine, which then begins the manufacturing process. However, the machine used is where knitwear and traditional 3D printing diverge. The primary difference from additive manufacturing is that the machine is not a 3D printer that processes filament or powder through extruders, rather, a knitting machine that can produce a three-dimensional garment in a single pass by uniting it thread by thread. Consequently, it should be noted that the principle is essentially the same both are based on software and are additively manufactured, but the material creates a big difference between the two methods.

Therefore, it is hardly surprising that industry experts agree in saying that 3D knitted goods are not manufactured using 3D printing, but rather, 3D knitting is a technology in its own right. Gerard Rubio, co-founder, and CEO of Kniterate, a company that sells 3D digital knitting machines, adds the following about his company’s machines and the use of the word 3D in connection with the production method: “These machines are capable of 3D knitting. But these machines are not necessarily 3D knitting machines.” This is because flat, single-layer garments like scarves can also be printed with a Kniterate machine, which eliminates the additive manufacturing aspect. Rosanne van der Meer adds that she deliberately uses the term ‘3D printed knitwear‘ for her products in order to make a clear distinction between 3D knitwear and conventionally produced knitwear.

Compared to Conventional Textile Production

Now that the differences and similarities between 3D knitwear and 3D printing have been outlined, the question remains whether and, if so, why 3D knitwear should be preferred to traditionally manufactured clothing. In order to provide a reasonable answer to this, conventional textile production must first be examined more closely.

This is still a touchy subject, with so few companies keeping their value chains and production methods transparent. Obvious and ongoing issues such as child labor, low wages, and inadequate protective measures in low-cost manufacturing countries are joined by the astronomically negative impact the industry has on the environment. From the cultivation of cotton, whereby both the use of pesticides and an enormous waste of water are recorded, to transit once the material has been broken down, and shipped to be processed into yarn and ultimately fabric in another country — this phase alone requires much examination for improvement.

Then, we have the woven fabric being sent back to be bleached or dyed at another factory. The harmful substances used in this process mostly end up in the wastewater, which in turn leads to the pollution of rivers and oceans. Lastly, the garment is sewn, knitted, and finished again in a different facility, with a large amount of material being wasted in the manufacturing process. The finished products are sent to the various branches around the world. The unbelievably long transport routes, which significantly increase Co2 emissions, rounds out the disadvantages of conventionally produced clothing. Although there are of course also smaller manufacturers who pay attention to sustainable, fair, and regional production, large-scale fashion producers that use traditional production channels still dominate the clothing market.

There are many problems with the conventional textile methods of large-scale fashion producers. These include the exploitation of workers in low-wage countries and the negative impact on the environment.

These social and environmental problems are primary focuses for CEOs Gerard Rubio, Gihan Amarasiriwardena, and Rosanne van der Meer, which is why they all pay attention to sustainability in the development of their companies and in the manufacture of their products. Awareness begins with the procurement of materials: While more than half of all clothing is produced using man-made fibers, mainly polyester, but also nylon, elastane, and acrylic, which are obtained from fossil fuels and therefore have a negative environmental impact; new industrial methods use merino wool which is obtained sustainably and as a natural fiber which generally has a smaller footprint compared to synthetic fibers.

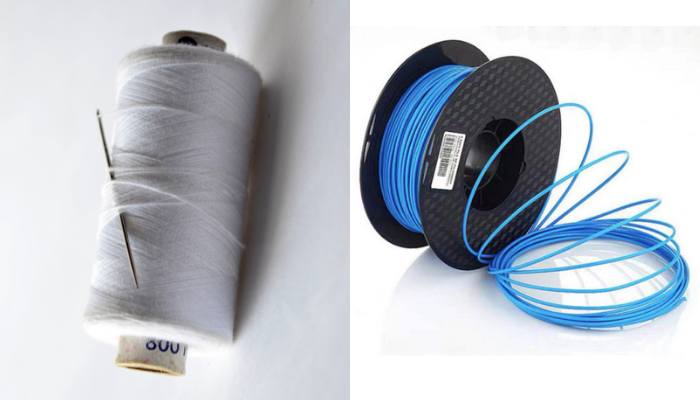

Rosanne van der Meer also adds that she relies on high-quality yarn in order to achieve the best possible results and in order to not run the risk of the thread breaking in the middle of the knitting process and thus having to restart production. A special feature here: even if the thread were to break, the half-finished knitted part could be recycled since the knitwear is designed in such a way that it can be separated again. This means that the material used can be recovered — another sustainability factor. As far as the material is concerned, large savings can be made using 3D knitwear, as the machines produce additively In just one pass and therefore only requires the threads that will be used, thereby eliminating numerous production steps and saving a lot of time and costs. Gihan Amarasiriwardena confirms this statement: “With 3D-printed knitwear, only the required fabric is used. This results in approximately 30% less material waste”. Sustainability also plays a role at Kniterate. Gerard Rubio relies on plant-based yarns, which can be recycled, so items of clothing that are no longer wanted can be disposed of properly and not end up in a landfill.

The material plays a huge role in the manufacture of 3D knitted fabrics. (Photo Credit: Kniterate)

Since 3D knitwear is on-demand production, problems such as overproduction and inventory waste can also be avoided. Large-scale fashion producers are not able to react flexibly and quickly to changes in the market mainly due to long supply chains, which results in overproduction and overstocking. This is a fatal flaw in today’s fast fashion industry, where new collections and goods hit stores nearly every week. And where should the “old” items of clothing go that have not been bought? These resource and energy-intensive manufactured textiles mostly end up in the garbage or are partially incinerated. On-demand production that takes place on-site/in-house could be a solution here. Not only are transport costs and emissions saved as a result, but practically significantly less waste is produced.

This goes hand in hand with Rosanne van der Meer’s motto: “The starting point for a better climate balance in the fashion industry is less consumption. If you have timeless clothing that fits you really well, you will also consume less.” Thanks to 3D technologies, it is also possible to personalize 3D knitwear. Since the designs are created digitally and every needle stitch is equivalent to a pixel, patterns can easily be modified and adapted to customer requirements, which allows a lot of freedom. A special program from the start-up Shavatar also helped New Industrial Order to improve the accuracy of fit of their 3D knitwear without a 3D scanner – an essential aspect when it comes to buying clothes. With the help of the open-source system and the knitting machine from Kniterate, users are obviously also open to all creations and personalizations. Last but not least, the typical problems such as the exploitation of workers through in-house, regional productions are also eliminated.

Challenges of 3D Printed Clothing and Predictions for The Future

After explaining the numerous advantages offered by 3D knitwear, the question now remains as to why it is not yet increasingly available in stores. What are the current challenges and what improvements may still need to be made? Will 3D printed clothing and especially 3D knitwear be the future of the fashion industry?

Indeed, additive manufacturing of apparel faces a number of challenges. As mentioned earlier, the material is probably the biggest obstacle – which is why 3D knitwear is being resorted to. When a closer look is taken at previous projects involving 3D-printed clothing, such as products by fashion designer Danit Peleg, it quickly becomes apparent that the options are limited: The materials compatible with a 3D printer are mostly plastics such as ABS, PLA or the currently very popular and very flexible TPU. Although the latter can be used to create stretchy, movable 3D objects, it doesn’t begin to compare to the soft, comfortable texture of fabric. Although it could now be argued that the majority of conventionally produced clothing is also made of synthetic polymers, i.e. plastic, the problem lies with the texture. It makes a big difference what form the material is in: Fibers and threads have a filigree, elastic and flowing state, whereas filament has a comparatively thick, hard and rigid state.

3D-printed clothing differs in texture from conventionally produced goods. (Photo credit: Danit Peleg)

Furthermore, most 3D printers cannot produce fine enough details. Unlike 3D knitting, where the moving threads are processed by many small needles, the extruders of a 3D printer cannot produce anything comparable. The structure and texture of 3D-printed clothing is heavy and pitted, and the surface texture is likely to be quite cold and unpleasant. Gerard Rubio agrees, saying, “At this point, the materials are not developed enough. However, I strongly believe that 3D-printed clothing will be the future.”

With regard to 3D knitwear, other problems are encountered. Rosanne van der Meer particularly emphasized here the difficulty of creating the digital codes for the knitting machine. That is why she relies on extensive databases, suitable non-fiction books and an open-source system. The latter should support New Industrial Order’s goal of creating a workflow that makes the codes for 3D knitwear accessible to all those who show interest. Gerard Rubio echoes this sentiment. He, too, describes developing the right parameters as a major challenge. The road from the prototype to the final, commercializable Kniterate machine, which is very complex, was long and difficult, according to him. Referring to the future, however, Rosanne van der Meer sees no problem in this regard: “The technology is already established and ready to function, but the current system works completely differently.”

The biggest difference between 3D printed objects and 3D knitwear is the material. It is easy to see that much finer structures can be created with threads.

This is because on-demand production, which is the principle of most current 3D knitwear manufacturers, completely contradicts the market flow. The current fashion market is based on mass production and mass consumption. Changing long-established systems and breaking habits is extremely difficult, which is why more sustainable companies specializing in on-demand production and customization face a major hurdle in entering the market. Also, in terms of production costs, 3D knitwear cannot compete with conventional clothing due to low market compatibility. Therefore, the current products from New Industrial Order and Ministry of Supply are still rather in the luxury segment in terms of price, within the framework of which customers are willing and able to spend a lot for personalization, sustainability and quality.

However, the experts are confident that 3D printing will play a greater role in the fashion sector in the future and firmly believe that novel technologies will revolutionize it. Rosanne van der Meer summarizes: “Changes in the textile industry are slow. Yes: in the future we will find more additively manufactured clothing, but how far this progress is in the future cannot be said.”

Ministry of Supply offers, among other things, 3D-printed blazers and masks. (Photo Credit: Ministry of Supply)

What do you think of 3D printed knitwear? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Photo Credit: New Industrial Order

We are considering purchasing a clothes-making machine with 3d printing.

They are trying to produce clothes made by weaving them with threads, not plastic clothes.

Please let me know the name of the machine, the price, and the time to make one top uniform.

Please give me your phone number and e-mail address.

I’m Kim Kwan Sik in Korea.

I’m going to make clothes with 3d printing.

Among your products, 3D printing that makes clothes with cloth.

If there’s a price, time to make a uniform, and the production period.

I would be grateful.

Hi! We developed an innovative way to produce textiles with a 3D Printing device.

In fact, we make a non-woven fabric, but you have the flexibility to use a wide variety of yarns and there are not gauge limitations.

Furthermore, you get shaped pieces and textiles can be disassembled in order to re-use yarns again and again.

We are currently at pre-launch phase, but you can get in touch visiting our website!

L

I’m looking to do my first production run of urban style and college prep wear. From what I’ve seen you have a great reputation. I would like to see if we can work together. Do you do this garment category? Would you be interested in giving a quote?

Can someone print a clone of my Teddy Bear ?