3D Printing Used to Create Titanium Alloy With Highest Strength to Weight Ratio

One of the key to modern manufacturing is research and development into materials. Especially in industries like aerospace, materials that are both lightweight and extremely strong are critical for the parts that need to be made. Indeed, material research for additive manufacturing in and of itself is a rapidly expanding field. In the latest news, engineers at Monash University used 3D printing techniques to create an ultra strong commercial titanium alloy, allowing applications in a number of critical industries.

Titanium is one of the strongest materials available and as such is often used for end-use parts. Titanium alloys, wherein titanium is mixed with another metal to provide additional properties including flexibility, strength and malleability, are particularly prized for their strength to weight ratio. But research is constantly being done to improve them. In the study “Ultrastrong nanotwinned titanium alloys through additive manufacturing,” the engineers showed how they were able to use additive manufacturing to create a titanium alloy with the highest specific strength (strength to weight ratio) .

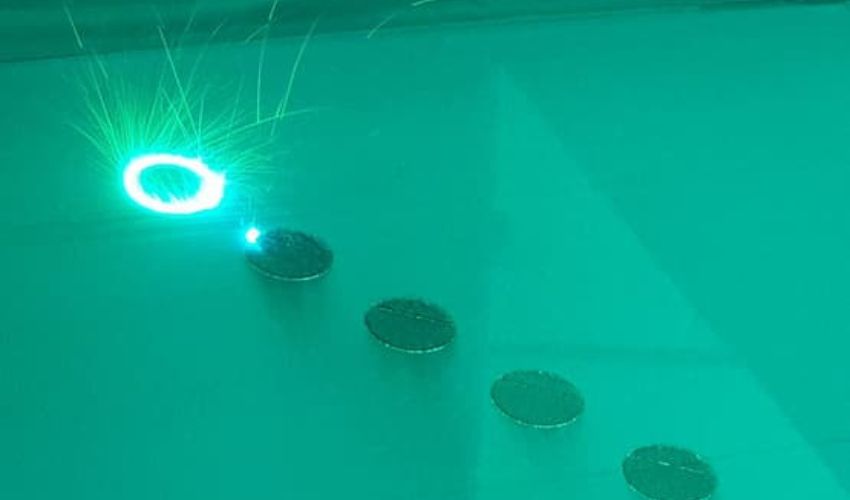

Titanium, both in its pure and alloy form, is used for applications in a variety of fields including aerospace thanks to its high strength-to-weight ratio (photo credits: Lupus in Saxonia, CC BY-SA 4.0 , via Wikimedia Commons)

Using Additive Manufacturing to Make a Titanium Alloy

It is important to note that, as might be expected, it is not an easy nor straightforward process to create titanium alloys. Rather they require a number of complex techniques including casting and thermomechanical processing. And though this does not mark the first time that 3D printing has been used not just to create parts but also the alloys themselves, often commercially available alloys made using it do not have the satisfactory properties. The researchers, lead by Professor Aijun Huang and Dr Yuam Zhu from Monash University used a 3D printing to manipulate a novel microstructure which resulted in an unprecedented mechanical performance for the alloy.

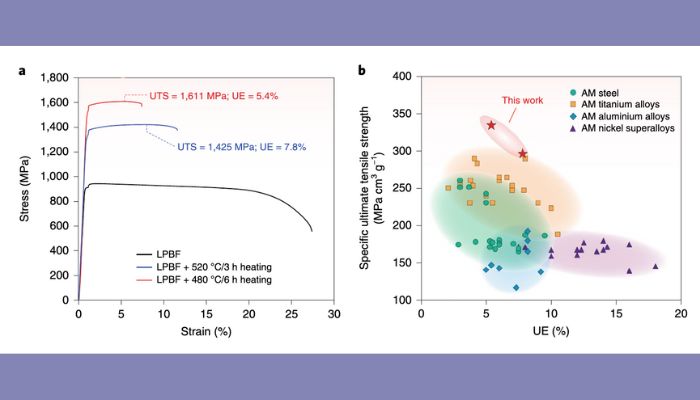

To do this, the researchers used additive manufacturing to exploit thermal cycling and rapid solidification. Specifically, the β-titanium alloy (Beta-C, Ti-3.63Al8.03V-6.02Cr-4.03Mo-4.00Zr (wt%), a commercial titanium alloy) powders were melted and deposited using laser powder bed fusion (LPBF). These specimens were then subjected to heat treatment at two different temperatures. Testing was then down which showed that the titanium alloys became stronger through this method, though the researchers believe it could be applied to any titanium alloy with the same results.

The tensile mechnical response of commercial Beta-C titanium alloys produced by LPBF and post-heat treatments (photo credits: Monash University)

Professor Huang further explains, “Titanium alloys require complex casting and thermomechanical processing to achieve the high strengths required for some critical applications. We have discovered that additive manufacturing can exploit its unique manufacturing process to create ultrastrong and thermally stable parts in commercial titanium alloys, which may be directly implemented in service. After a simple post-heat treatment on a commercial titanium alloy, adequate elongation and tensile strengths over 1,600 MPa are achieved, the highest specific strength among all 3D printed metal to date. This work paves the way to fabricate structural materials with unique microstructures and excellent properties for broad applications.”

The researchers hope that the findings in the work will lead to insights in the principles of strengthening and dislocation engineering in the field of physical metallurgy. They also noted that by using 3D printing with a simple heat treatment, the process cost was significantly reduced compared to materials with a similar strength. You can download the full research paper HERE.

What do you think of this new titanium alloy? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Monash University