3D Printing Glass at Room Temperature: Myth or Reality?

Glass is a material that we encounter every day, and it can be found in many forms. It also has interesting characteristics for numerous applications: transparency, chemical inertness, electrical insulation, heat resistance and recyclability. However, despite its advantages, it is still not often used for additive manufacturing, as it requires very high melting temperatures around 1,000°C, and a highly controlled thermal environment. Yet, a recent project at Lincoln Laboratory could change all that. A team has succeeded in 3D printing glass objects at low temperatures: their technique, direct ink printing, enables the process to be started at room temperature, followed by a heat treatment at just 250° C.

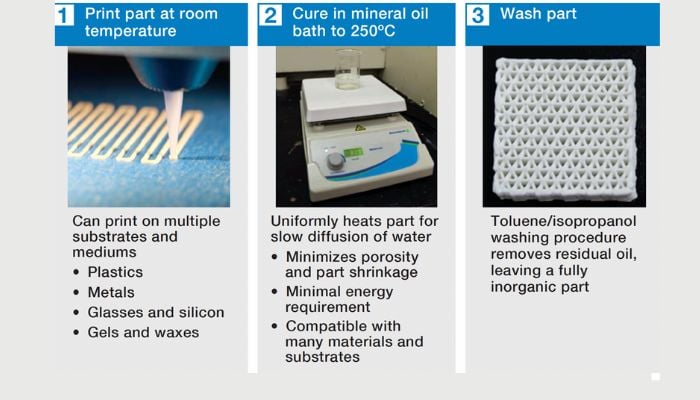

The direct ink printing technique uses a tailor-made ink composed of a silicate solution and nanoparticles of other inorganic substances. This is then extruded, layer by layer, through a 410-micron nozzle, ensuring very precise control of the printing process. The ink can be deposited on a plastic, metal, glass or silicone substrate, all at room temperature. The silicate particles react with each other and with the silica particles to form a three-dimensional part.

The 3D printing glass process in three steps

After this room-temperature printing stage, the team proceeds to a post-processing phase to guarantee the part’s structural stability. The part is placed in a mineral oil bath heated to 250°C. It is then completely hardened. Finally, it’s cleaned in an organic solvent (a mixture of toluene and isopropanol) to remove any residual mineral. According to the Lincoln Laboratory team, the tests carried out resulted in structures with very high resolution, less shrinkage and very good thermal stability.

So, the initial results are promising. Does this mean 3D glass printing will be more accessible? Admittedly, the post-processing steps add to the length of the manufacturing process, but the considerable reduction in processing temperatures is a major advantage. For the time being, the team explains that it is working on improving the optical clarity of the glass produced, as well as developing other inks that would offer different chemical and electrical properties. In the meantime, you can find out more HERE.

What do you think of the Lincoln Library’s method? Have you ever 3D printed glass? Let us know in a comment below or on our LinkedIn or Facebook pages! Plus, don’t forget to sign up for our free weekly Newsletter to get the latest 3D printing news straight to your inbox. You can also find all our videos on our YouTube channel.

*All Photo Credits: Lincoln Laboratory