3D Printed Fashion: The Top Designs

Fashion brings together several industries, whether it is clothing, cosmetics, or luxury. All sorts of products are being created to embellish and affirm a style, a look, a way of being. In the world of fashion, it is necessary to know how to stand out and how to present ever more original and innovative designs. For that reason, many brands and designers are now turning to 3D technologies, which is understandable, given the number of new options the technologies present to express creative freedom while allowing mass customization and a reduction of environmental impact. The textile industry, as you’ve probably already heard, is known to have a negative impact on our planet. 3D printing, however, presents an opportunity to mitigate these effects, by using only the material that is necessary and by producing on demand. What applications of 3D printing are available today in the fashion industry? From haute couture dresses to handbags, we’ll take a look at a few initiatives, listed in alphabetical order.

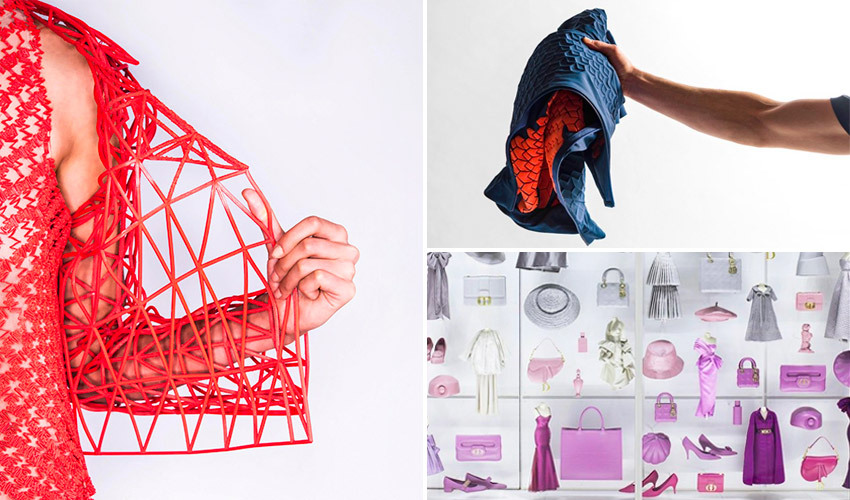

NFT Collection by Danit Peleg

Danit Peleg is the first designer in the world to have created a collection entirely using desktop 3D printers. The structure of his designs is inspired by mixing traditional textile properties with new technologies, which is how this lace-like texture was created. According to the designer, 3D printing allows digital fashion to become physical, which reduces the limits of creativity. The garments are printed layer by layer with a flexible filament using a desktop 3D printer to create a three-dimensional structure that fits the body shape. Danit Peleg believes that in the near future, we will have more wearable materials made by additive manufacturing to choose from.

Iris van Herpen

Dutch designer Iris van Herpen was one of the first to use 3D printing in the fashion industry. She already managed to impress everyone at this year’s Met Gala with her extraordinary 3D printed creations which were worn by Teyana Taylor, Winnie Harlow, and Fredrik Robertsson. At this year’s Fashion Week in Paris, she also unveiled a 3D-printed haute couture dress that was developed in a collaboration between the designer and Belgian ice cream brand Magnum. The dress was made entirely from a vegan organic material based on cocoa bean shells. Iris van Herpen’s work is an intersection of fashion, design, technology, and science. In her designs, she brings together nature, fashion, and technology by using unconventional materials and technologies and combining them with traditional sewing techniques.

Galerie Dior

Additive manufacturing also found its way into the field of haute couture, as the example of the reproduced fashion pieces at Galerie Dior in Paris shows. On display at the Boutique Dior located in the world-famous Avenue Montaigne, interested visitors can find several hundreds of 3D-printed replicas of former Dior garments, handbags, or even shoes. The manufacturing process took place thanks to the collaboration between the ALIGHIERI agency and LA FERME 3D ©. Together, they invested over 100,000 hours of printing and 10,000 hours of post-processing in the reproduction of the fashion elements. The printing was done by more than 30 3D printers, which were put to work for a total of six months, day and night, to complete the iconic Dior project. The material used for the production is entirely bio-based.

Kornit Digital and Its 3D Printed Knitwear

The high amount of society’s consumption of fast fashion was the turning point for Ronen Samuel, CEO of Kornit Digital, a sustainable fashion brand that uses additive manufacturing to produce knitwear. For its sustainable and waste-reducing fashion, Ronen uses direct-to-yarn printing, which is printing directly onto all types of textiles. In this case, the company uses MAX technology, which applies ink layer by layer. The result is a garment that looks like it was knitted traditionally. Ronen Samuel’s designs have already been presented at the Tel Aviv Fashion Show.

A 3D Printed Skeletal Mask for High Fashion

A great example of how 3D printing can be used to create a unique piece that can even give an outfit the missing touch which ultimately completes it is this skeletal mask created by designer Kevin Freitas Conlin. The exotic-looking accessory, that was worn by drag queen Aquaria on the tenth season of the popular show Ru Paul’s Drag Race, helped her win in the show’s final. The bone-like structure of the mask, which was customized to Aquaria’s face, was reportedly 3D-printed in laser-sintered nylon by American AM company Shapeways. This was the first time that 3D printing technologies were used on the show, and it inspired designers in later seasons of Ru Paul’s Drag Race to experiment with it as well and create other unique pieces, such as the fashionable exoskeleton worn by contestant A’whora during season 12.

Julia Daviy’s 3D Printed Skirt

Julia Daviy started creating 3D printed fashion back in 2017 and has since released a variety of amazing 3D printed clothing collections. With a special focus on sustainability, the California-based fashion designer, who has quickly become a pioneer of sustainable 3D-printed fashion, designed and produced many examples of fashion, jewelry, and home décor. One interesting example of her work is The Organic Skirt. This particular piece is the central element of a 3D-printed collection that was released in 2019. In the project titled the After Forever Collection, all items of clothing were 3D-printed by using large-format 3D printers. The Organic Skirt was the first digital 3D-printed piece of clothing available on the U.S. market and is digitally customizable in over 1,000 variants.

VIP TIE

VIP TIE is an Italian company that is famous for 3D printing ties. The goal of the company is to offer fashionable accessories that are as personalized as possible in order to satisfy the needs and desires of the customers. VIP TIE combines both luxury and innovative high-tech design. The creation process of just one tie can include an intricate mix of several complementary procedures and materials: craftsmanship, embroidery, 3D printing, exotic leather, mother-of-pearl, carbon fiber, silver, gold, and silver plated solid. Apart from highly customizable products, another advantage of VIP TIE is that more than 80% of the materials used are 100% environmentally friendly.

Patronace

Patronace is a sports brand created by award-winning designer Bastian Müller. The Munich-based brand offers 3D printed activewear for those who lead a fast-paced lifestyle. The clothes are made for everyday urban mobility, no matter if you commute by skateboard, scooter, or e-bike. For the production of the clothes, the brand uses a lightweight and flexible textile printing technology called GRDXKN, which transforms substrates into smart textiles. This unique material, with which Patronace manufactures these garments includes integrated protection and insulation, and has a special kind of grip thanks to the textile layer that controls moisture, is breathable, water repellent, abrasion resistant, and shock absorbing. The fashion created by the company with its intelligent textile allows you to feel both, safe and stylish at the same time.

3D Printed Leather Which Could Revolutionize the Fashion Industry

When it comes to materials in fashion, one that will never go out of style is leather. For jackets, boots and everything in-between, leather is a cornerstone in the industry. However, ethical use of the material can be difficult. Real leather is often touted as far superior to its alternatives, but many still would prefer leather to be animal free. Thankfully, researchers from Tufts University might have a solution. Using silk cocoons from the silkworm Bobmyx mori and 3D printing on a custom-built pneumatic extrusion 3D printer, the researchers were able to produce an environmentally friendly, animal-free leather alternative that not only resembles real leather but also has the same mechanical properties. Though as of now they have only made a wallet out of the material, the find could have a major impact on the fashion industry at large in the near future.

Stratasys and The SSYS 2Y22 Reflection Collection

Recently, well-known manufacturer Stratasys introduced its new commitment to the 3D printed fashion world with the launch of its J850 TechStyle 3D printer. Following that, the American-Israeli company has continued to demonstrate the capabilities of additive manufacturing in this field. During Milan Design Fashion Week, it unveiled its SSYS 2Y22 Reflection collection, consisting of high-end accessories and apparel, which were all 3D printed. This was possible thanks to the collaboration with 7 other groups of designers that, together with the technology of its J850 TechStyle solution, allowed the development of an innovative line of products that aim to reflect the social impact observed in recent years. In the video below you can see the use of 3D printing to create these fashion garments, specifically from the hand of Ganit Goldstein, one of the designers who participated in the SSYS 2Y22 Reflection:

What do you think of this 3D printed fashion? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.