3D Printing Brings a Sea Monster to Life

You might have seen the recent story about the discovery of the giant fossil that was extracted in the UK in the beginning of December 2023. The skull of a pliosaur, an ancient marine reptile from the Jurassic period, was first found on the cliffs of Dorset’s Jurassic Coast, a world heritage site consisting of Triassic, Jurassic and Cretaceous cliffs, by amateur fossil hunter Phil Jacobs. Indeed, the discovery was documented in the show “Attenborough and the Giant Sea Monster” which aired on the BCC on January 1st and followed famed naturalist Sir David Attenborough as he investigated this fossil. But did you know that 3D printing was also used to help understand and visualize this so-called sea monster?

To understand how 3D printing was used, it is first important to understand why exactly this discovery was so important. The two-meter skull which includes 130 teeth is one of the biggest and most complete specimens of its type, and it would have never been discovered if the snout had not been happened upon by chance when it fell onto the beach. Pliosauroidea, which are more commonly referred to as pliosaurs and nicknamed the ‘Tyrannosaurus rex of the seas‘, were apex predators in the Jurrassic and Cretaceous periods. But a lot of mystery surrounds these gigantic creatures, especially in terms of how they moved given their size, hence the title sea monster.

The skull fossil of the pliosaur (photo credits: BBC Studios)

Making the Giant 3D Printed Sea Monster

Pliosaurs had a powerful bite (as obvious in the picture of the skull fossil), generating 33,000 newtons of force. An incredible amount considering that the living animal with the most powerful bite today is the saltwater crocodile, which only generates 16,000 newtons, and humans can only generate 700 newtons. It also was fast and moved thanks to four powerful flippers. These flippers are where scientists have been stumped, as it was unclear how they could be used to propel the enormous creature through the water. Enter Dr. Luke Muscutt and James Hogg.

Dr. Luke Muscutt, who is currently a laboratory technician at Imperial College London, has been working on finding out more about plesiosaurs (the family to which the plisaurs belong) since his PhD and his findings in 2017 were critical in settling a debate in how the creatures used their flippers. He explained, “We found that plesiosaurs used a tandem flipper propulsion system, meaning the four flippers work together to push them through water. This system is unique, because all other animals with flippers, like penguins and turtles, only use the front two for propulsion, and the back flippers or feet for steering. We studied this by building a tandem flapping flipper system mounted on a gantry, without a head or tail.”

This work however was stalled even as he wished to create a fully-formed robot. But, this changed after meeting James Hogg, who had recently opened the Yorkshire Natural History Museum in Sheffield and agreed to support Dr Muscutt’s work. Indeed, this incredible, free-swimming robot replica’s body plates (or the ‘skin’) were made using a metal 3D printer at the Yorkshire Natural History Museum. He explained why the team turned to additive manufacturing, stating, “The joy of 3D printing is that the majority of the work lies in the computer-aided design. Once it’s perfect on the computer, you just print it, with no messing around later – other than the assembly and a bit of sanding and painting.”

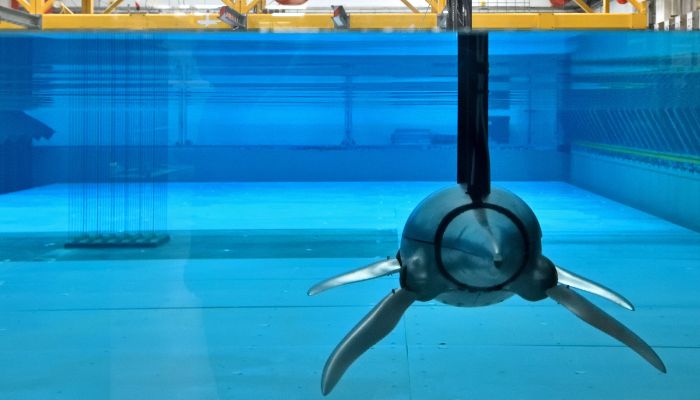

The 3D printed ‘sea monster’ pliosaur swimming (photo credits: Jo Mieszkowski/Imperial College London)

The final robot was able to swim at Imperial’s state-of-the-art wave tank and was shown not just to Sir David but to millions in the broadcast. Thus giving a clearer understanding to the viewers on how this so-called sea monster would have actually moved in real life, bring the past into the future thanks to 3D printing. And it is not expected to stop there! Dr. Muscott plans to redesign the pliosaur, affectionately nicknamed Flip, to make even more realistic flipper motions and hopefully determine the speed of the creature as well as see how its head and neck are involved in steering.

To do this, 3D printing will be used to help recreate the delicate internal bone structures of plesiosaur flippers, emulating the flexibility of the flippers more realistically. This will also be helped by a change in printer, Dr. Muscutt has now secured sponsorship from FormLabs through Creat3D, meaning the next iterations will likely be made of TPU or another flexible polymer for even more accuracy. You can find out more about hte project as well as the making of the documentary on Imperial College London’s website HERE.

What do you think of the use of 3D printing to recreate this ‘gigantic sea monster’? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.