3D Printing at the Heart of Automotive Interior Design

While additive manufacturing has proven its worth in the production of spare parts, tooling and finished parts for the automotive sector, it is also very popular for vehicle interiors. The car’s interior is an increasingly important space for the driver: they are looking for comfortable, practical and efficient functions, but also a certain style. While some drivers are completely indifferent to design when it comes to driving, others feel that the dashboard, seats, gearshift lever, etc. should stand out from the crowd. Carmakers are therefore striving to create luxury interiors with new details that will make all the difference. To achieve this, many are relying on the flexibility of 3D printing. As we all know, it not only enables greater personalization, but also the design of complex shapes. From 3D printed headrests to revamped dashboards and personalized accessories, here are just a few applications of 3D printing in automotive interior design.

Alpine Integrates 3D Parts into Its Electric Vehicle

After having worked on a series of customized accessories for the Peugeot 308, the French 3D printing service ERPRO has announced a new collaboration with the Alpine brand. This time, the protagonist is the A390_β, the brand’s first 100% electric sports vehicle. This innovative model incorporates several 3D printed parts using SLS technology. For its manufacture, Pebax® Rnew®, a bio-based elastomer developed by Arkema, was used, highlighting Alpine’s commitment to sustainability and advanced technologies. In addition, the printed models feature a transparent coating that evokes the appearance of ice blocks, a detail that reflects the brand’s inspiration from nature. This development is part of Alpine’s ongoing effort to incorporate innovative and eco-friendly solutions into its vehicles, combining design, technology and respect for the environment.

Credit: ERPRO

3D Printed 18-karat Gold in the Bentley Batur

In 2022, British automaker Bentley Motors Ltd unveiled the Bentley Batur, named after a lake on the Indonesian island of Bali, touting it as one of the most powerful Bentleys ever built. Equipped with a hand-assembled 6.0-liter W12 engine with twin turbochargers, the Batur boasts over 740 horsepower. However, what truly caught our attention was the use of 3D printing in its design. The vehicle features 18-karat gold organ stops for ventilation, while the exhaust finishers were 3D printed in titanium—demonstrating how additive manufacturing is shaping luxury automotive craftsmanship. With only 18 units produced, the Batur is an ultra-exclusive model, offering buyers an exceptional degree of customization. As Bentley puts it: “From the main exterior paint to the surface finish of the air vents, and literally everything in between, each customer will specify even the tiniest of details.” This level of personalization underscores how 3D printing is driving a broader shift toward bespoke design in the automotive industry.

Credits: Bentley Motors Ltd

115 3D Printed Parts in the Cadillac Celestiq

The 2024 Cadillac Celestiq impresses with 115 3D printed parts. The metal steering wheel was 3D printed, as well as the window switches, door handles and console decoration. The 3D printed steering wheel in the Celestiq can have custom coating and finishes, and also be engraved. Certain safety features of the car were 3D printed too, including the seat belt buckles. These 3D printed parts opened pathways for customization, a common theme seen among luxury cars. The Celestiq, for one, had a price starting at mid-$300,000, setting it far above many of Cadillac’s other models, but with that price point, buyers get access to a personal Cadillac design concierge. The buyer can then choose the bespoke materials and finishes that will bring their Cadillac to life.

Ford Integrated Tether System

Do you own a Ford Maverick and are interested in 3D printing? Ford has the perfect project for you! Back in 2022, Ford unveiled its Ford Integrated Tether System (FITS) in the Ford Maverick® pickup. What does this mean? Well, thanks to a series of slots at the rear of the center console and the under-seat storage bins, the vehicle is compatible with accessories, allowing users to customize their car. These include Ford premade accessories, but it is also possible to make it your own with those you have made with your own 3D printer (or from a service provider of course). The possibilities are endless! Ford even provides the files to get you started, a maker’s dream.

A bin divider, one of the possible accessories that Ford Maverick owners could 3D print and place in their car (photo credits: Ford)

Lamborghini Sián

Among the brands using additive manufacturing to design their cars is the well-known luxury brand Lamborghini. The first car to feature customizable 3D printed interior parts was the Sián FKP 37, Lamborghini’s first hybrid car. This one features center and side dashboard vents produced with 3D printing. Only 60 units were made of this top-of-the-line hybrid model, with as many vents. In terms of timing, 3D printing made it possible to go from the initial idea to the final part installed in the car in just two weeks—a time unthinkable with other traditional technologies.

Credits: Lamborghini

The Headrests of the Maserati GranTurismo Fuoriserie One Off Luce

3D printed decorative elements were also chosen for the new interior of the Maserati GranTurismo Fuoriserie One Off Luce. For this model, which was presented at Milan Design Week, the carmaker’s team designed an interior that combines technological innovation and sustainability. 3D printing enabled advanced design solutions, while the use of ECONYL® nylon helped reduce environmental impact. It is, in fact, a yarn obtained by recycling plastic materials, such as fishing nets and textile scraps. Inside the Maserati GranTurismo One Off Luce, the famous Trident logo was printed directly on the sand-colored headrests using J850 Tech Style from Stratasys. Thanks to this solution, it was possible to customize the fabrics with exclusive textures and details. The concept of the sea and sustainability also returns in the interior furniture elements. The idea was to create a monochromatic design in a single shade of blue, in perfect contrast to the sand-colored seats, which refers to the color of the ocean from which the recycled material comes. The blue interior blends perfectly with the car’s mirrored chrome exterior, the effect of which immediately hints at a futuristic, minimalist design.

Credits: Maserati

MINI Electric Pacesetter

The MINI Electric Pacesetter, the first electric safety car for Formula E, combines the innovation of electric mobility with the advanced customization enabled by 3D printing. This model, inspired by the MINI Cooper SE and designed in collaboration with BMW and the FIA, stands out for integrating 3D printed parts, such as interchangeable and customizable pads on the sports seats, which adapt to the driver’s complexion and preferences without compromising safety and comfort. In addition, its aerodynamic design incorporates elements printed with recycled carbon, such as fairings and the rear spoiler. This safety car was launched in 2021 and its function was to enter the track and slow down the peloton in case of accidents.

Credits: BMW Group

Oechsler Car Seats

The driver’s seat is an important element of driving, especially when it comes to circuit racing. It’s a dimension that TECHART wanted to emphasize in its GTstreet R Flyweight model, a racing car limited to 19 units based on the Porsche 911 Turbo S. To achieve this, TECHART approached Oechsler to redesign the seats. The aim was to offer both personalization and a superior level of performance. The result was 3D printed seat cushions: manufactured using Multi Jet Fusion and TPU, they incorporate lattice structures that not only lighten the load but also improve ventilation. Cushioning properties are also enhanced. Finally, thanks to 3D printing, pressure points are reduced, temperature is also reduced (by 3 to 5°C) and seats can breathe better, offering a better driving experience. What’s more, the assembly of the 3D printed cushions is rapid and can be carried out from one race car to another without difficulty.

Race car seat with 3D-printed cushions (credits: TECHART)

3D Printing for the Peugeot 208

To equip the Peugeot 308, a range of innovative 3D printed accessories has been created with a collaboration between Peugeot, HP, Mäder and Erpro Group. The collection includes holders for glasses, phones and boxes, made from a TPU specially developed to meet the demands of the automotive sector. This unique material, developed with BASF and HP, offers great flexibility and exceptional durability. These accessories, designed to absorb impact while boasting an impeccable finish and precise detailing, illustrate a modern, technological approach to automotive design, combining practicality and aesthetics.

Credits: Peugeot

3D Printed Bodyform Full Bucket Seat from Porsche

Since February 2022, Porsche has been offering tailor-made bodyform full bucket seats for various Boxster, Cayman and 911 models as part of the Performance Parts program, which can be selected directly in the Porsche Car Configurator. Parts of the cushion and backrest surfaces are produced using 3D printing, which enables individual customization. The seats are also manufactured by combining the lightweight base support made of expanded polypropylene (EPP) with a breathable comfort layer of 3D printed polyurethane material. The 3D printed full-shell seat is also available in three degrees of firmness, allowing it to be adapted to the customer’s different needs and body contours. Another advantage is that the seats are 8% lighter than traditional bucket seats. In addition, the full bucket seats can not only be ordered for new vehicles but can also be retrofitted to models that have already been delivered.

Credits: Porsche

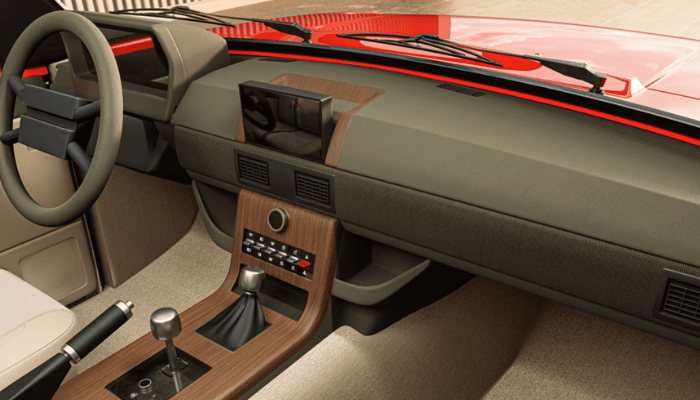

LUNAZ’s Range Rover Safari

The company LUNAZ, which was founded to reproduce iconic car models of the past by making them electric and enhancing their features, is certainly not lagging behind when it comes to the use of technology. For its Range Rover Safari electric car, the LUNAZ team chose to use 3D printing to improve the functionality and aesthetics of the interior, while maintaining the identity of the iconic model from the last century. For this vehicle, the spartan dashboard and interior of the original version were replaced with a new, larger and more modern console made using 3D printing. This component, developed by the design team over two years of research and development, will become a feature of future electric Range Rovers of the LUNAZ brand. In addition, following the circular economy principle based on recovery, the scanning of vehicle components plays a key role in the restoration process. Indeed, this makes it possible to create precise CAD models, ensuring accurate technical reproduction of the original components and enabling the correction of any defects. LUNAZ offers a wide range of customizable interior options, including high-quality materials such as vegan leather and fine woods, as well as textile upholstery that pays homage to the original Range Rover Classic interior.

Credits: LUNAZ

3D Printed Interior Accessories for the Renault 5 E-Tech

Renault has been using 3D printing for several years to meet a variety of needs, from prototyping to the manufacture of specific tools and final parts. With the Renault 5 E-Tech, 3D printing also finds its place in the passenger compartment. Customizable storage accessories, available in a range of patterns and colors, have been created to optimize the central space. These elements combine practicality and aesthetics. If this model meets with the expected success, 3D printing could play an even greater role in Renault’s future production.

Credits: Renault

What do you think of 3D printed parts for car interiors? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! If you are interested in more automotive 3D printing applications, click here. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.