3D Printing for Adhesive-Free Wood and Polymer Bonding

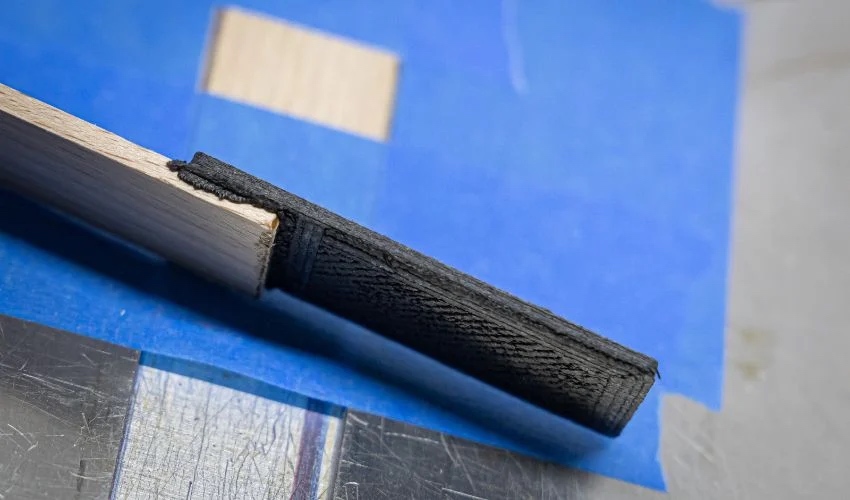

What if you could glue plastic to wood without adhesives or chemicals? That’s the goal of a team of researchers from Graz University of Technology in Austria. They used additive manufacturing to deposit different materials on wood, layer by layer, and called their technique “AddJoining.” These materials actually penetrated the wood, creating these extremely strong bonds. Several materials were tested, including polyamide and carbon-fiber-reinforced polyphenylene sulphide, on both oak and beech. Thanks to this technique, the team hopes to reduce the environmental impact of industrial glues and adhesives.

The glues used in industry are often synthetic, obtained from hydrocarbon derivatives and the chemical industry. As a result, they do not degrade and make recycling of certain products extremely difficult. Although so-called natural glues are becoming more and more widespread, with even initiatives around so-called biodegradable solutions, efforts are not sufficient and the reality is less green than we’d like. To combat this problem, a team of researchers in Austria has come up with the AddJoining technique.

From left to right: Awais Awan, Sergio Amancio and Gean Marcatto from the Institute of Materials Science, Joining and Forming at TU Graz (photo credits: Wolf – TU Graz).

In concrete terms, this involves depositing the material on untreated wood instead of a conventional printing plate to create joints between the two materials. You can imagine the constraints involved, but the initial results are encouraging. Gean Marcatto, one of the researchers, explains: “After the joint fractured, we were able to find polymer in the wood pores and broken wood fibers in the polymer, which suggests that the fracture occurred in the wood and polymer, but not at the joint.”

The researchers explain that they could achieve even more satisfying results if they treated the wood with a nanostructure via laser engraving, for example. This would increase the pores and improve adhesion. Sergio Amancio, one of the team members, continues: “But we wanted to work with as few steps as possible and, above all, without chemicals. We can use this technology particularly well with complicated 3D geometries because the components are printed directly onto the surface – in whatever geometry is required.”

Ultrasonic Joining (photo credits: Wolf – TU Graz)

A second technique has been developed, Ultrasonic Joining, which has nothing to do with additive manufacturing: it consists of joining two materials through the production of ultrasound and heat. To find out more about these two methods, click HERE.

What do you think of the AddJoining method? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Wolf – TU Graz