3D Printer Accessories for Improving Your Printing Experience

The success of a 3D print depends largely on the machines and materials you use, but that’s not all. The accessories and tools you have also play a key role in the 3D printing process. There are specific options that can facilitate each phase of the process, from model preparation to post-processing. These accessories, whether useful before, during or after fabrication, can ensure that the results are just as you imagined them. In addition, many of them improve precision, finishing quality and process efficiency. Here is a complete selection of must-have accessories to optimize the performance of your 3D printer and achieve quality prints, even in the smallest details.

3D Printer Accessories Before 3D Printing

The Digital Caliper

A digital caliper is a tool for measuring exact lengths, diameters and depths, all in an easy-to-read manner. In 3D printing, it is an essential tool for obtaining accurate parts, as well as facilitating the creation of full-scale designs or reverse engineering projects. Compared to a tape measure or other measuring tool, a digital caliper offers superior accuracy, and its use ensures that each part fits perfectly. They are also useful for checking filament thickness so that extrusion flow can be adjusted to avoid problems such as over-extrusion or under-extrusion. Nowadays the offer of digital calipers is quite wide, with inexpensive options ranging from 20 euros to professional options of more than 300 euros.

Photo credits: Protolabs

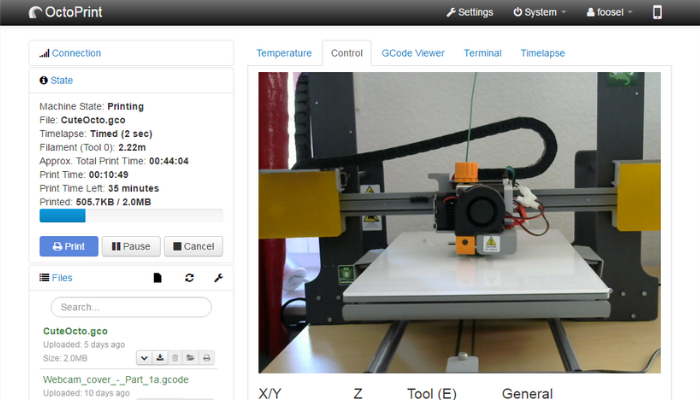

Remote Control Solutions

Remote control solutions for 3D printing are useful tools when you want to keep an eye on printing while you are away from home. Everyone can make use of these solutions: whether you have a single desktop printer or a farm of printers and need to coordinate the actions of multiple machines. Various types of software allow convenient remote management, such as OctoPrint, Fluidd, and Mainsail, and smartphone apps such as Bambu Handy, which is only compatible with Bambu Lab brand solutions. There are also dedicated hardware solutions such as the Raspberry Pi, which when combined, for example, with Klipper firmware, can allow each maker to optimize the extrusion speed of their printer remotely.

Photo credits: OctoPrint

Filament Storage and Dryers

Filaments, especially very hygroscopic ones like PETG, TPU or Nylon, absorb moisture from the air. Using moist filament like this can negatively affect the quality of prints, causing bubbling and popping in the hot end, flow irregularities and stringing. To avoid these issues, you can invest in proper filament storage. Air-tight containers, vacuum-sealed bags and specialty filament boxes can work. If you already have moist filament on your hands that needs drying, you can purchase a filament dryer, which often includes automatic drying capabilities, a scale and temperature indicators. Typically, these can house one to two spools, and can also be programmed to feed filament into the printer.

3D Printer Accessories During Printing

Extra Build Plates and Nozzles

Both extra build plates and nozzles can come in handy during 3D printing. In terms of build plates, it is recommended to have at least one extra. Why? Well, it will always be faster to remove a build plate and put in a new one than remove the just finished part when needing to print multiple parts. Additionally, some users claim that having multiple build plates can be useful as each one can be optimized for printing with a specific material.

Additional nozzles can also be handy. First, in case the nozzle gets clogged, switching it out with a spare while it is cleaned will ensure no delays in printing. But nozzles also come in different sizes. From the smallest at 0.1 to the biggest at 1.0, nozzle size directly correlates to the final part. Small-diameter nozzles are useful for fine details, although they are slow, while large-nozzle diameters allow for a greater volume of material extrusion and shorter printing times, although detail is sacrificed. A nozzle of 0.4mm is standard for FDM printers but it is possible to buy a nozzle set with different sizes, or just a few others to allow for variety.

Different nozzle sizes for a 3D printer (photo credits: Top 3D Shop)

Improving Material Adhesion

The adhesion of the material to the 3D printing plate is a key aspect during the process of creating any part. The better the adhesion, the higher the quality of the final part. This is especially important at the beginning, as the first layer must stick firmly to the plate to ensure good deposition of the following layers. This will also prevent warping, which occurs when the plastic layers shrink and peel off. For this purpose, there are several types of bonding accessories that we can use on the 3D printing tray. These can be glue sticks, such as those of the Magigoo brand, but also lacquer sprays such as those offered by 3DLAC. Finally, we can use adhesive tape that sticks easily and facilitates the removal of parts from the tray.

On the left, the 3DLAC spray; on the right, the Magigoo glue stick

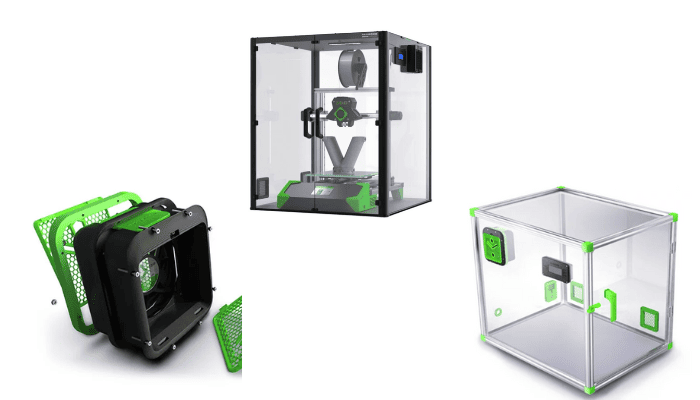

Emission Protection

To limit exposure to emissions generated during 3D printing, several solutions are available. Indeed, research has revealed a significant production of nanoparticles as well as the release of VOCs, directly linked to the composition of filaments. Repeated exposure to this polluted air can be harmful. To remedy this, various protective options are available. For example, Alveo3D offers several solutions, such as an air filtration system to attach to a housing, a housing kit with integrated filtration, a custom enclosure for desktop 3D printers, and an industrial smoke extraction system, compatible with various equipment. According to the manufacturer, these solutions offer over 98% efficiency, while neutralizing odors and reducing symptoms of irritation.

Left, filtration system; center, kit; right, custom enclosure

Multi-Material and Multi-Color Upgrades

If you are just beginning with 3D printing, you might be satisfied with your first prints. However, you may soon want more creative freedom, with more colors and more materials. In this case, you can either replace the printer with a multi-color printer or buy an add-on that gives you more scope for your artistic ambitions. Many manufacturers offer such multi-color or multi-material upgrades for their own printers. Several spools of filament can be stored in these boxes, partially dried and made available for printing. The spools are usually changed automatically so that printing is not interrupted when several colors or materials are used and less waste is produced.

With the MMU3, Prusa offers an add-on for its original Prusa i3 MK3S+ and MK4. This allows you to print five filaments simultaneously. Bambu Lab has the AMS Lite in its range for its A1 series, an automatic material system for four filaments. The ACE Pro from Anycubic, the CFS from Creality, the Chroma Kit from Phrozen and solutions from Co Print also work in this way. Another tool that is compatible with various printing solutions is the Mosaic Palette. Although there are now different versions of it, the principle remains the same. The palette combines filament sections in such a way that a single strand is created and the print is made in one filament strand in several colors or materials.

Post-Printing Accessories

Spatula

Another practical 3D printer accessory is the spatula. These are mainly used to remove the printed parts from the printing bed without damaging them. Since the parts can adhere firmly to the printing plate, a spatula can help to remove them carefully, avoiding deformation or breakage. In addition, on printers without a flexible plate, the squeegee is essential for peeling off objects without applying too much force. In some cases, they are also used to remove filament residues or media after printing. They come in different sizes and with vertical and slightly raised handles. Your choice will depend on the function you are looking for.

Photo Credits: Amazon

Knives, Pliers & Deburring Tools

Printing objects with a high level of detail can require a slightly longer post-processing job, because certain details may need additional refinement. For a perfect result, you can use a small knife and pliers to remove excess material. Deburring tools, which can come in the form of various shapes and sizes, are made to remove burrs (a raised edge or small piece of remaining material) and sharp edges. With its swiveling, curved metal blade, a deburring tool can smooth out the edges of a part and remove rough pieces.

Small knives (top), Klein Tools pliers (right), AFA Tooling deburring tool (bottom)

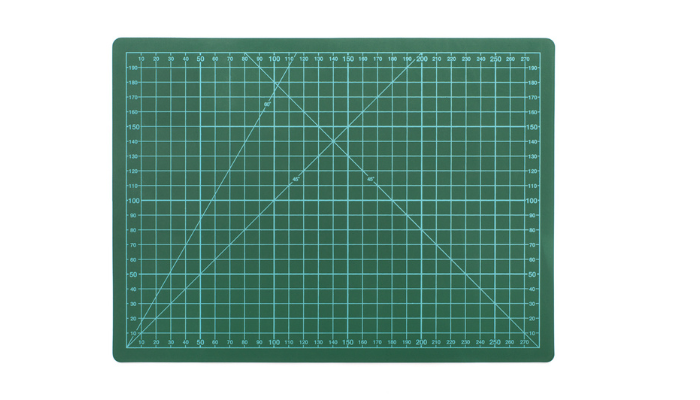

Cutting Mat

The cutting mat is a useful tool for those working with 3D printing. It is mainly used to protect the work surface during model manipulation in some post-processing stages, thus allowing surfaces to be saved from accidental cuts or scratches. Some mats have self-healing properties, keeping the surface smooth despite cuts. In addition, this backing allows you to work on a safe and stable surface that also provides a good grip. It is recommended that mats with grids and measurements printed on the surface be used as guides to make more precise cuts.

Which of these 3D printer accessories do you already use? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.