3D Printed Thermostable Vaccine Patches

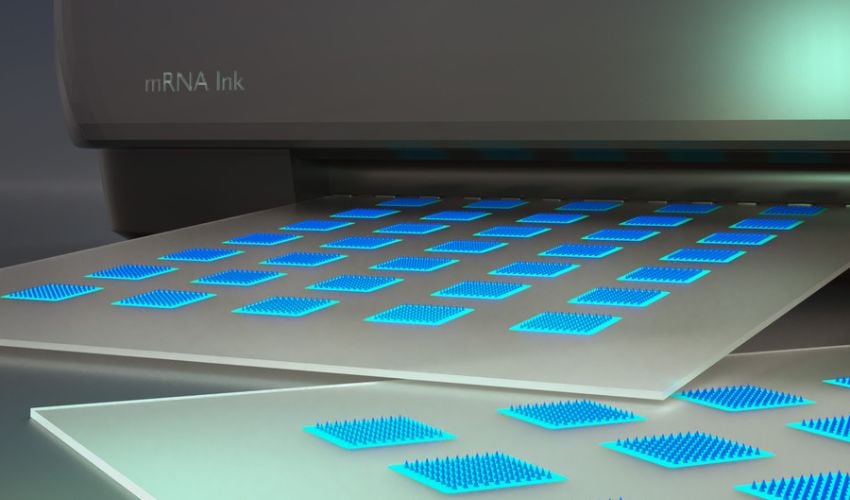

Are 3D printed vaccines the future? Researchers at MIT have developed a portable 3D printer capable of printing ready-to-use vaccine patches that are thermostable, meaning they can be stored for months at room temperature. Eventually, the machine will be able to print hundreds of vaccines per day.

This is not the first time a vaccine has been 3D printed, and with the same patch structure housing microneedles. The novelty here lies in the fact that it is possible to store vaccines at room temperature. This last point responds to a major problem concerning the transport and conservation of vaccines. A large part of traditional vaccines, including RNA vaccines, must be stored at low temperature, which complicates their transportation and storage in areas that are difficult to access, such as deserts, war zones, etc.

The project objective was to respond to the problem of Ebola-type epidemics by transporting printers to the region concerned in order to rapidly vaccinate the population. With the emergence of the Covid-19 pandemic and issues regarding access to vaccination and vaccine stability, the team reoriented the project to produce RNA (mRNA) vaccines to fight against the disease. Messenger ribonucleic acid (mRNA) is a molecule found in all cells of the body. Within each cell, the information encoded in the mRNA is read and converted into protein. In the case of Covid-19 vaccines, the mRNA is converted into the S (Spike) protein, which is also present on the envelope of the virus responsible for Covid-19, thus triggering an immune response when infected with the disease.

For example, in a study published in Nature Biotechnology, MIT researchers show that the printer is capable of producing heat-stable mRNA vaccines against Covid-19. These vaccines, administered with the same dosage as vaccines given by injection, trigger a comparable immune response in mice.

How are These 3D Printed Vaccines Made?

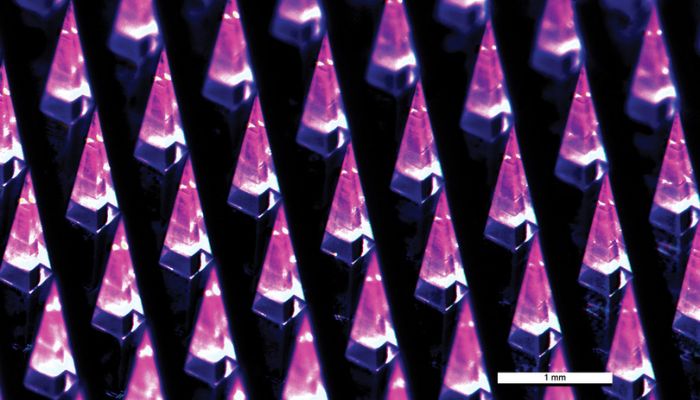

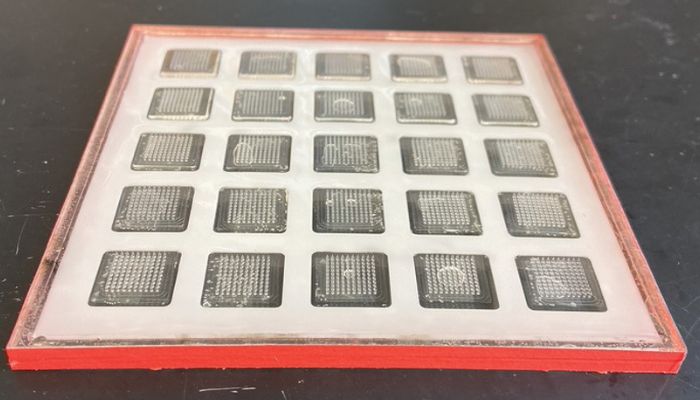

Each patch, about the size of a thumbnail, is made up of hundreds of vaccine-filled microneedles. To make them, the printer’s robotic arm injects ink into the microneedle molds. A vacuum chamber under each mold draws the ink to the bottom to ensure that it reaches the end of the microneedles.

The printer prints patches containing hundreds of vaccine-filled microneedles (photo credit: MIT)

Example of a mold (photo credits: MIT)

Currently, the production capacity of the printer made by the MIT researchers is 100 patches in 48 hours. However, they hope to increase this to 100 patches per day by improving the efficiency of the machine.

A Process Adaptable to any Type of Vaccine

The researchers involved in the study plan to produce other types of vaccines by adapting the process used for mRNA vaccines. Vaccines made from inert proteins or viruses will also be involved. “The composition of the ink has been a key element in stabilizing mRNA vaccines, but the ink can contain different types of vaccines or even drugs. So this microneedle system allows for great flexibility and modularity of delivery,” says Ana Jaklenec, a researcher at MIT’s Koch Institute for Cancer Research, one of the senior authors of the study. In any case, for more information on this study, see the MIT press release and the full study HERE.

What do you think of the 3D printed thermostable vaccine patches? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

Photo credits: Ryan Allen from Second Bay Studios