3D Printed Sushi Could Be the Food of Choice for Space Travelers

Over the past few years, we have seen a number of applications for 3D printing in both food and space. Now, the two are getting combined. Engineers at IHI Aerospace and Yamagata University, in partnership with Nordson EFD Japan, have developed 3D printed sushi that they hope will be served to space tourists as they circle the plant in low Earth orbit.

It should come as no surprise that space tourism is a pricey endeavor. Current offerings range anywhere from $250,000 for a seat on a 90-minute flight to well over $20 billion. Why then should the food you eat not also be special? For IHI Aerospace and Yamagata University, 3D printed sushi was the answer, thanks to sushi’s mass popularity worldwide and 3D printing’s ability to reduce weight.

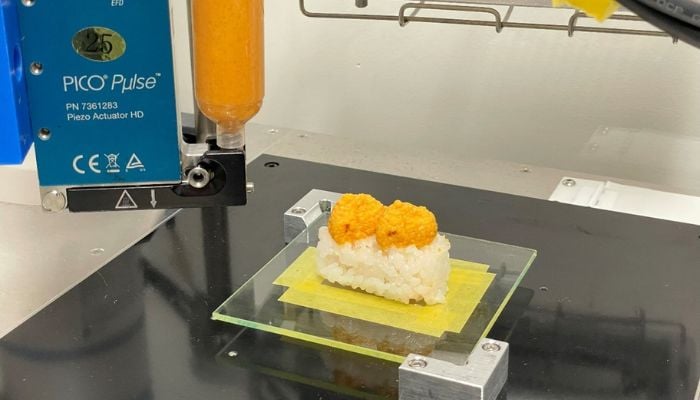

The prototype solution used to 3D print sushi

What Do We Know About the 3D Printed Sushi?

As mentioned, the idea to serve 3D printed sushi in orbit corresponds to the fact that every gram matters when you are in space. This also meant that it was necessary to look beyond the usual pillars of sushi making, including specialty chefs, sharp knives and many different kinds of fish and seafood. Rather, IHI Aerospace and Yamagata decided that the most important was to embrace the simplicity of sushi, focusing on fresh ingredients, balanced flavors and beautiful presentation. The solution was to create proteins in a paste.

Paste is a common material format for food 3D printing, one that we have seen in many other projects over the years. In this case, they decided to turn to uni (sea urchin) paste, in particular for inspiration, which is already used due to uni’s low shelf-life when in its original form, whereas pastes are shelf stable. Still, there were problems to address before the 3D printed sushi could start being made, namely with how to properly deposit the paste. This is where Nordson EFD Japan came in.

The sushi immediately after 3D printing

The goal of the program was to produce four types of 3D printed sushi: uni, white fish, crab and shrimp. And the 3D printing solution would need to be able to toggle between the four with no taste residue. Not only that, but the paste would need to be deposited without disturbing the bed of rice. To accomplish this, Nordson EFD used the PICO Pulse jet valve system, which uses a piezoelectric actuator for smooth, accurate dispensing of fluids. This was then combined with a Touch valve controller and fluid reservoir, as well as a flat nozzle with a 300-micron orifice.

The resulting prototype was a success. The end product looked artistic and consistent even in multiple tests and was even served to dignitaries at a major Japanese trade show. In addition to travel in space, the IHI Aerospace/Yamagata University team also note that the 3D printed sushi could be used in hospitals, nursing homes and long-term care facilities.

It should be noted that for now, this is just an idea. While the initial story broke in 2024, as far as we know there has been no move to start implementing this plan on any spacecraft. But who knows? As the space tourism grows, perhaps it will catch on. In any case, 3D printed sushi is a very cool application for 3D printing.

What do you think of this 3D printed sushi? Would you try it? Is 3D printed food the answer to feeding space tourists while in orbit? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Nordson EFD

I love seeing the power of 3D Printers. The sushi looks so yummy and realistic.