Researchers Create 3D Printed Surgical Table

North American University researchers recently announced the successful creation of a 3D-Printed surgical table. The project, a collaboration between the University of Western Ontario (Western) and Michigan Technological University (Michigan Tech), was conducted using open-source hardware and resulted in the production of a fully functional medical application that cost only a fraction of its regular cost.

Everyone knows medical equipment is expensive, no matter what kind it is. The surgical table market in North America alone exceeded $456 Million in 2021 and is expected to grow a lot more in the coming years. Such a high number is no surprise, considering that a single surgical table can cost up to $250.000. For developing countries, where such equipment is needed at least as much as here, the inability to pay those steep sums ultimately results in patients not receiving the treatment they need. As an incentive to make surgical tables more affordable and easier to supply to countries around the world, the researchers from Western and Michigan Tech turned to additive manufacturing. 3D printing, as you might know, has already proven itself to be a promising alternative to traditional manufacturing methods in many industries, enabling faster, cheaper, and more sustainable productions.

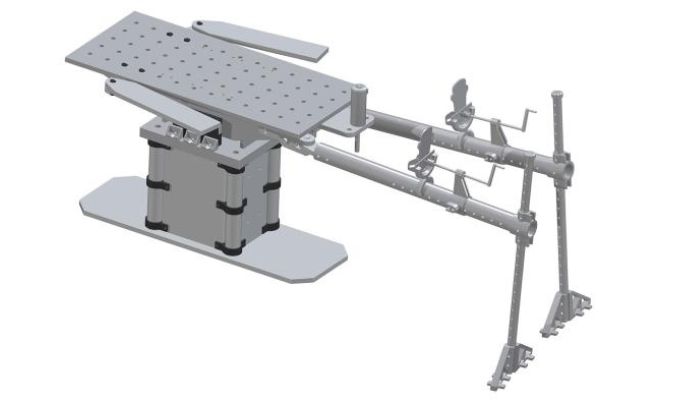

Model of the 3D printed surgical table (photo credits: Western University)

Printing The Surgical Fracture Table

After carefully deliberating what would be the best way to complete the job, the team decided to use an open-source desktop 3D printer, which enabled them to produce the necessary components. The entire printing process was finished in a little more than a week, and the end product, a fully functioning surgical fracture table, only cost around $4,000. Compared to the regular price of $250.000, that is a total discount of 98.5%. According to Joshua Pearce, John M. Thompson Chair in Information Technology and Innovation at Western, materials were used that are widely available worldwide.

The surgical fracture table consists of different components and can be adjusted 35.5″ to 46″ in height and tilted from +/-15 degrees. Its leg height can be changed from 12″ to 46″ and the arm supports and foot holder both have a 180-degree range. The foot traction has a range of 21″, and the legs can be adjusted from 55 to 120 degrees. The table can be used for a wide range of orthopedic procedures. In addition to that, it is also ideal for general surgical procedures, as well as gynecological procedures and childbirth. Especially for developing countries, the 3D printed surgical table offers an affordable alternative to the overpriced general ones.

The 3D printed table when finished (photo credits: Western University)

Joshua Pearce explains, “Medical technology is absurdly expensive. One way we can help reduce costs is to enable all manufacturers to build these, sell them directly, and to integrate some of the innovations, like the use of the radiolucent 3D-printed parts we made into their own designs,” said Pearce. “This is in no way the final fracture table. I’m sure any decent engineer could look at it and make it a little bit better and that’s exactly what it’s meant to do – to be a starting point for other people to build on.” The idea for the project came from the Western’s Frugal Biomedical Innovation Team. Its main purpose is to design, develop, test and deploy biomedical devices for communities where they’re most needed. They hope especially to provide solutions to communities with an underdeveloped medical infrastructure. You can read more about the team HERE.

What do you think of the 3D printed surgical fracture table? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Master Sgt. Carlotta Holley