3D Printed Spikes From BMW Are Being Used to Make Bobsledding Faster

In the sports sector, 3D printing is continuously being used to customize equipment for athletes, even at the highest levels. The increased relevance of 3D printing was once again demonstrated by the German Bobsled, Luge and Skeleton Federation (BSD). In cooperation with the BMW Group, its technology partner since 2010, the BSD is once again using 3D printing technology to prepare for two sporting events in the coming season, in particular for the production of 3D printed spikes for bobsled shoes.

The events in question are the FIL World Championships Luge (January 2024) and the BMW IBSF World Championships Bobsled and Skeleton (February–March 2024). In both sports, the main focus is on the speed and the resulting time of the athletes, which must be optimized. At the FIL Luge World Championships, the “BMW Data Coach” has been used in luge since 2016 as part of the BSD’s partnership with the BMW Group. This technology enables the recording of run data to replicate the athletes’ luge runs in the ice channel. This allows individual recommendations to be passed on to the athletes, leading to the refinement of their riding behavior and their luge and skeleton equipment. Of course, if we are speaking personalization, we must also turn our gaze towards additive manufacturing.

Bobteam Friedrich – (c) BSD/Viesturs Lacis

3D Printing to Guarantee Success in Bobsledding and Skeleton

This trend of advancing personalized adaptation of conditions to the individual athlete and the respective environmental conditions is also supported by current developments in 3D printing. At the upcoming BMW IMSF Bobsled and Skeleton World Championships, for example, athletes will be provided with individually customized spike plates for bobsled boots made by 3D printing. The hope is that these should increase their chances of winning immensely.

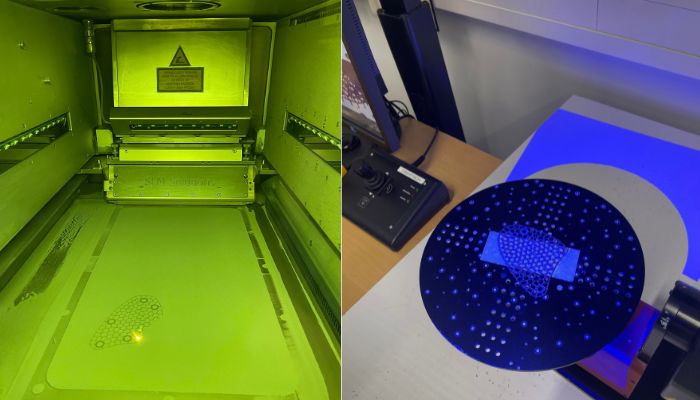

How? Well, additive manufacturing makes it possible to determine the optimal placement of the spikes on the bobsled boots, as well as the optimal number of teeth and struts that should be attached to the boots. In addition, the weight and stiffness of the shoes can be flexibly adapted to the athlete and the production of the spike plates saves time and costs compared to conventional manufacturing processes. Due to the low costs associated with printing the spike plates, many prototypes can be printed until a model suitable for the athlete is achieved. Recently, athletes have even had the opportunity to try out 3D-printed spike shoes made from different materials.

In addition, design software is now also used for the production of spike plates for bobsled. The software takes personalized 3D scans of the athletes’ shoes as a basis and uses them to print the spike plates individually adapted to the athletes. All this is done by including the optimal arrangement, number and shape of the spikes and the stiffness. This process increases flexibility and reduces production time enormously.

The adjustment of the bobsled boots is decisive for the athletes’ start time and thus the total run time, as the spike plates on the forefoot soles determine the strength of the push at the start of the run and thus the acceleration. In this process, the technology of manufacturing and development in the automotive industry is used by BMW and BSD to better adapt the spike plates to the athletes. 3D printing has been an integral part of BMW’s processes since 1991. You can find more information HERE.

3D printed spikes for bobsled shoes

What do you think of the 3D-printed bobsled spike shoes for the upcoming championships? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: BMW Group