3D Printed Smart Gel Adapts Colour and Shape with Light

A team of engineers at Rutgers University have developed a 3D printed smart gel that is able to sense and change according light exposure, becoming “artificial muscle”. The smart gel was inspired by the colour and texture changing mechanism of cephalopods such as octopuses, cuttlefish and squid which possess colour changing cells called chromatophores in their skin. Using a variation of SLA technology called multimaterial projection microstereolithography, the researchers were able to transform hydrogel into a smart gel, by incorporating light-sensing nanomaterials. The team also developed a 3D printed stretchy material, which, when combined with their light-sensitive smart gel achieves a camouflage effect, adapting its colour according to change in light. This innovation has the potential to lead to new advances in military camouflage, soft robotics, targeted drug delivery, flexible displays and improved prosthetics.

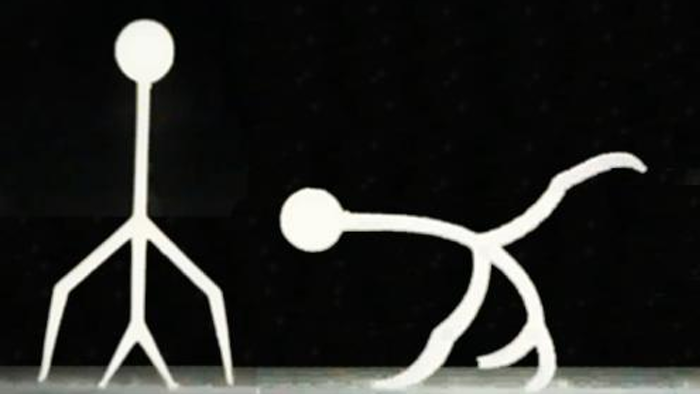

In 2018, Rutgers engineers invented the “4D printing” method for their smart gel. The fourth dimension referring to the ability of the 3D printed object to change shape over time. This version of the gel altered its shape according to temperature change. The research demonstrated that the high-resolution, scalable, and efficient additive manufacturing of hydrogels was not only possible, but could be achieved without compromising their shape and solidity despite their high water volumes. A few months later the team made further advancements in their research, and developed a 3D-printed smart gel able to walk underwater and grab and moves objects in response to electrical stimulation. On the subject, Howon Lee, senior author of the study and an assistant professor in the Department of Mechanical and Aerospace Engineering said “Our 3D-printed smart gel has great potential in biomedical engineering because it resembles tissues in the human body that also contain lots of water and are very soft.”

A human-like 3D-printed smart gel walks underwater. (Photo Credit: Daehoon Han/Rutgers University-New Brunswick)

Additively manufactured hydrogels, fundamental to the smart gel, are no longer a novelty in the medical sector, having already been the basis of several innovations including a life-sized anatomically accurate model of a human heart, contact lenses, a new method of administering cancer treatment, and brain implants, among others. Hydrogels are useful because they are able to contain water while still maintaining shape and solidity. While they exist naturally and can be found in the human body, hydrogels can also be produced by additively manufacturing highly hydrated polymer networks.

The newest version of Rutgers’ smart gel is controlled by changes in light rather than electricity. This permits a far wider range of applications, than its predecessor which required electrical stimuli. Moreover, thanks to its flexibility the smart gel is able to bypass obstacles which limit the potential applications of other technologies. Lee notes:“Electronic displays are everywhere and despite remarkable advances, such as becoming thinner, larger and brighter, they’re based on rigid materials, limiting the shapes they can take and how they interface with 3D surfaces. Our research supports a new engineering approach featuring camouflage that can be added to soft materials and create flexible, colorful displays.” Now, the research team aims to improve the technology’s sensitivity, response time, scalability, packaging, and durability.

What do you think about this new research into smart gels? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox!