3D Printed Skin Can Replace Animal Testing for Cosmetics

The skin is the largest organ we have in terms of surface area and whatever we apply to it is able to affect the body directly via the various layers. There it can fulfill its purpose, for example relieve pain and contribute to regeneration or even cause great harm. This is the case when ointments, cosmetics etc. contain toxic substances. To rule this out in advance, cosmetics are subjected to numerous tests for purity and compatibility. In order to protect us humans, animals are often used for such tests however, these are increasingly considered to be ethically reprehensible as they cause great suffering to animals. But what are the alternatives for testing sunscreen and other products and guaranteeing their safety? A team of researchers from Graz University of Technology and the Vellore Institute of Technology (VIT) in India created a 3D-printed skin that imitates the human model and is to be used for tolerance studies in the future.

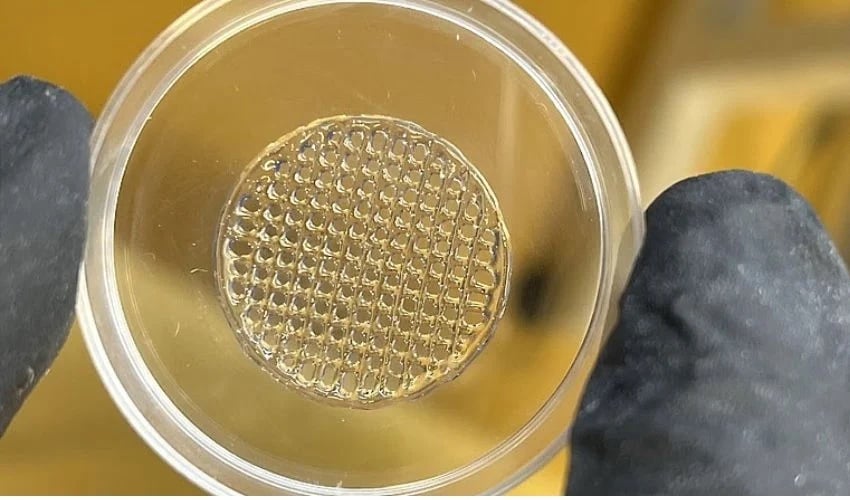

The imitation skin was produced using 3D printing and is enriched with living cells. Like its biological counterpart, it has a three-layered tissue structure. In order to be able to print the imitation, hydrogel formulations had to be developed first. No easy task, as Karin Stana Kleinscek from the Institute of Chemistry and Technology of Biobased Systems at TU Graz points out. “The hydrogels for our skin imitation from the 3D printer have to fulfil a number of requirements,” she explained. “The hydrogels must be able to interact with living skin cells. These cells not only have to survive, but also have to be able to grow and multiply.”

3D-printed structure of the skin with human keratinocytes

Although hydrogels have a high water content, which is ideal for integrating cells and allowing them to grow, the high water content also leads to challenges. For example, the mechanical and chemical stability required for printing is impaired by the high water content. In order to solve the problem of stabilization, TU Graz worked on various cross-linking methods. The experiments were based on nature and the researchers aimed to avoid the use of cell-toxic chemicals.

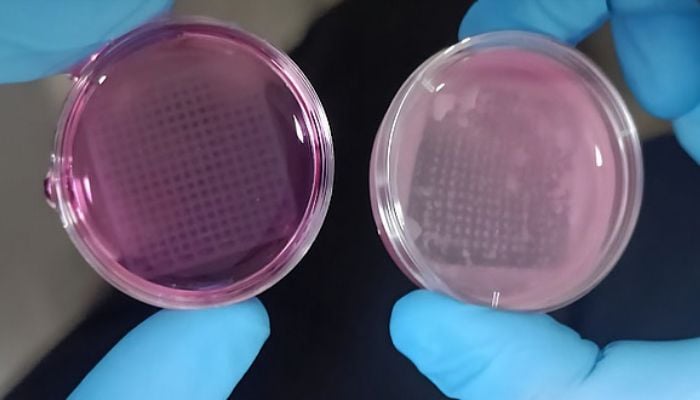

After successful stabilization of the hydrogels and printing, the 3D-printed skin was tested for resistance and toxicity. The cell culture was tested at the Vellore Institute of Technology in India. It was important that the cells were able to survive in the imitation for two to three weeks and that complete skin tissue developed. Only after this phase could the imitation be subjected to further cell tests.

According to Graz University of Technology, the initial tests were promising. The results showed that the cross-linked materials used for stabilization were not toxic and that the 3D-printed skin remained mechanically stable. “In the next step, the 3D-printed models (skin imitations) will be used to test nanoparticles,” says Karin Stana Kleinschek,” says Karin Stana Kleinschek, emphasizing how the combined expertise of the two institutions can help to reduce cosmetic tests on animals and the associated suffering. She continues:

This is a success for the complementary research at TU Graz and VIT. Our many years of expertise in the field of material research for tissue imitations and VIT’s expertise in molecular and cell biology have complemented each other perfectly. We are now working together to further optimise the hydrogel formulations and validate their usefulness as a substitute for animal experiments.

You can find out more HERE. What do you think of this 3D-printed skin? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel. You can also find more news in the medical and dental sector HERE.

*All Photo Credits: Manisha Sonthalia – Vellore Institute of Technology