The MIT Rocket Team creates 3D printed rocket using plastic

With the constant developments being made in 3D printing, it can sometimes be hard to keep up. But, there is always a piece of news that stands out from the rest, and this is one of them.

Recently, an independent student group at MIT called the “MIT Rocket Team” has designed a new and improved rocket that takes 3D printing to a whole new level. With 14 years of experience under their belt, this group was able to 3D print a rocket motor using plastic instead of metal.

When it comes to 3D printing parts for large scale projects such as seen with SpaceX, NASA or Lockheed Martin, the typical go to material is metal, for obvious reasons. But, for the MIT Rocket Team, 3D printing metal parts was not a viable option. This is due to it being a costly printing process, when looking at material and printer costs. The team therefore decided to try a new material, plastic.

Working alongside Markforged with their Markforged Mark Two 3D printer and their Onyx Material, the MIT Rocket Team set out to design and print a rocket part that was functional and strong. The results? An innovative rocket that uses a plastic motor instead of metal.

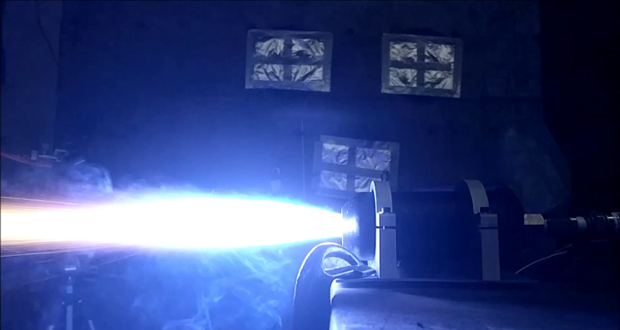

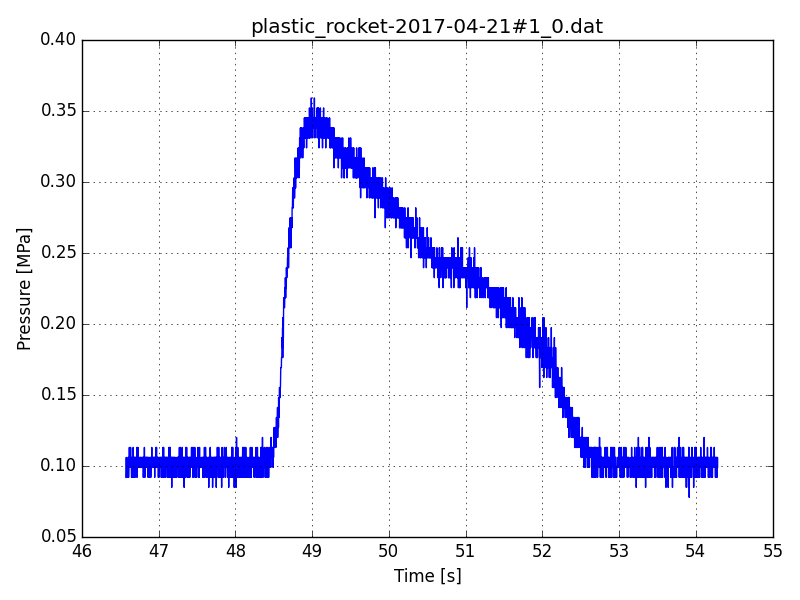

During their initial testing process, their rocket managed to survive and was able to achieve supersonic flow; producing thrust with only a few millimeters of plastic eroding from the throat. Although their rocket was created for only one use, the team decided to try the test again to see what would happen. Using a “more energetic propellant”, the results weren’t quite what they were hoping. This is due to the already worn throat, the rocket quickly becoming unstable, the nozzle becoming subsonic, and the rockets overall inability to produce enough thrust.

Following the results of their unique accomplishment, the team is already planning for their future work. Charlie Garcia, the Co-Outreach and Publicity Chair, explains that they will explore the use of “Larger motors, more resilient motors, and potentially even flight hardware.” Overall, the team is hoping that through their innovations they will be able to give a price accessible option to hobbyists and small teams.

To see their rocket in action, check out their short video below:

To find out more about the MIT team rocket’s rocket, check out their website here.

What advances do you think we’ll see in 3D printing with plastic? Do you think that the MIT Rocket Team is leading the way for more innovations using plastic? Let us know in a comment below or on our Facebook and Twitter page!