3D Printed Rocket Nozzle to Propel NASA Space Exploration

While private aerospace companies have been utilizing 3D printing technology to further their own stellar aims, the National Aeronautics and Space Administration has not been neglecting the additive manufacturing trend either. In 2023 alone they have 3D printed moon rover wheels, components for the International Space Station and utilized 3D printed circuitry aboard rockets, to name but a few projects which fall under NASA’s exceedingly concerted push to utilize additive manufacturing technologies for its rockets and space-bound initiatives. Most recently added to the list, NASA has successfully tested a 3D printed rocket engine nozzle made from aluminum, opening up new opportunities as the lightweight material allows for larger payloads to be sent into space.

The rocket engine nozzle was a cooperative effort between NASA engineers from the Marshall Space Flight Center and 3D printing company Elementum 3D based out of Erie, Colorado. The joint collaboration was to develop a new variant of aluminum which would be optimized for 3D printing rocket engine parts. Aluminum has been seen as a promising choice for additive manufacturing due to its high strength and low weight. Indeed, aluminum has already been used to 3D print various other mechanical parts in other sectors, such as gearbox and engine parts for automotive companies like BMW.

An image of the 3D printed nozzle on the laptop in the background and vacuum jacket manufacturing demonstrator tank used for cryogenic fluid application, made from the same aluminum material. (Photo credits: NASA)

But, when it comes to rocketry, the metal has not been used as often due to a low heat tolerance which leaves the metal vulnerable to cracking under the extreme heat of a rocket engine’s blast. However, under the NASA initiative known as Reactive Additive Manufacturing for the Fourth Industrial Revolution, or RAMFIRE, the team was able to engineer an innovative solution to overcome these previous obstacles, leaving aluminum with only its positive qualities.

The RAMFIRE 3D Printed Rocket Nozzle: A Game Changer?

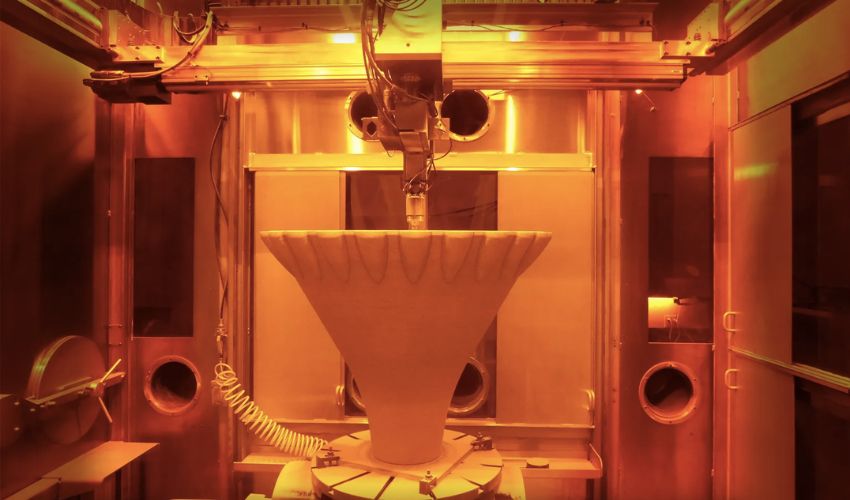

This technological advance was achieved in the design of the rocket nozzles themselves which feature small internal channels designed to redirect the heat and prevent the metal from melting. With the use of laser powder directed energy deposition (LP-DED) 3D printing, the RAMFIRE nozzle can be constructed as a single piece. The same part with traditional manufacturing methods would require thousands of separate pieces to be combined. The final parts were printed by another NASA partner, RPM Innovations, in Rapid City, South Dakota.

Paul Gradl, principal investigator of the RAMFIRE initiative at NASA’s Marshall Space Flight Center, spoke positively of the result and the collaboration across the board to develop and print the rocket nozzle, “Industry partnerships with specialty manufacturing vendors aid in advancing the supply base and help make additive manufacturing more accessible for NASA missions and the broader commercial and aerospace industry. We’ve reduced the steps involved in the manufacturing process, allowing us to make large-scale engine components as a single build in a matter of days.”

In an environment where the weight of a rocket is important down to the last gram, the reduction in weight comes as a major game changer for NASA and creates new opportunities for expanded travel to Earth’s orbit, the Moon, Mars and more. Testing of the parts has already been conducted, where the 3D printed nozzles were able to withstand extreme heat and pressure used to simulate scenarios in deep space.

After the success of the RAMFIRE rocket nozzle, NASA plans to expand its additive manufacturing to other projects involving aluminum material such as satellite parts. NASA also plans to further spread its research and increase collaboration with other AM companies, stakeholders and research bodies. For more information about the RAMFIRE 3D printed rocket nozzle, view their report HERE.

What do you think of the RAMFIRE rocket nozzle? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: RPM Innovation