Patient receives a 3D printed rib cage implant

In the medical sector, 3D printing has made some important advances in the last few months. Every step at this stage is important as it says a lot about the progress of the technology. Additive manufacturing enables personalisation of each medical device to respond to each patient’s specific needs, this is one of the most important benefits of this technology and likely the future of tailor-made medicine. Just recently in the UK, a patient successfully received a 3D printed cage implant. The surgery took place in Birmingham, at Queen Elizabeth Hospital – the patient in question is 52-year-old, Linda Edwards.

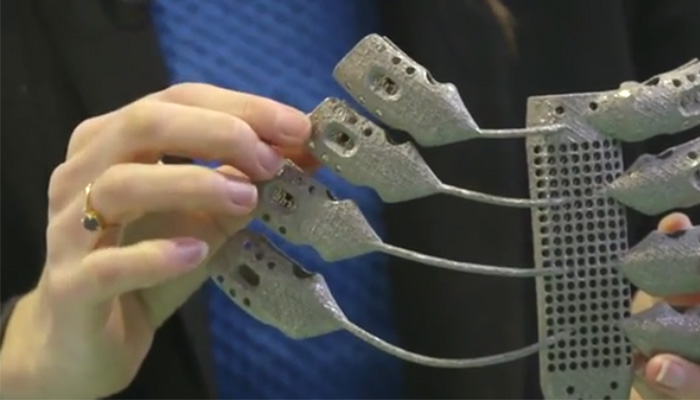

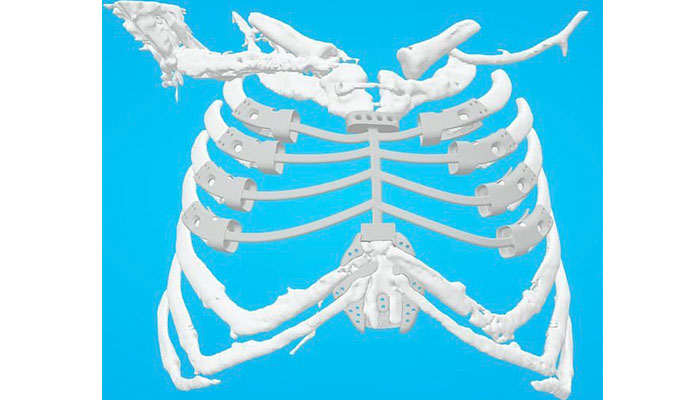

The rib implant was 3D printed in titanium, a material we know is biocompatible. During the operation, the surgeon Ehab Bishay replaced the portion of the patient’s damaged rib cage with the 3D printed titanium device to add support. Linda Edwards was only the sixth person in the world to have this type of surgery.

A 3D printed rib cage

In Linda’s case, she had a collapsed breastbone due to issues from a previous operation and was initially told that her rib cage could not be repaired. She began having symptoms of indigestion and heartburn in 2016, therefore surgeons had to cut her sternum to access her heart. In this operation, the sternum was repaired using wires, which did not end up holding up and her sternum finally collapsed. In 2017, a similar surgery led to her sternum collapsing once more. Linda Edwards was desperate to find a solution and that’s when she decided to contact Ehab Bishay after seeing a documentary highlighting Bishay’s work with 3D printed transplants. She said: “It was out of sheer desperation that I contacted Dr. Bishay because the situation with my rib cage was critical. It was getting steadily worse and I couldn’t see a way forward.”

The surgery was carried out in July 2019 at Queen Elizabeth Hospital in Birmingham, the titanium implant used in the operation was resistant to infection, functional, strong, and lightweight. “It’s fantastic to see that Mrs. Edwards is doing extraordinarily well given the complexity of the procedure she has undergone. That is due in part to the collaborative working of three highly-skilled surgical teams and their focus on improving long-term outcomes for patients by developing its capacity and experience to undertake these highly-complex procedures” said Dr. Ehab Bishay.

“The plastic surgery team, led by Mr. Haitham Khalil, harvested several muscle flaps to cover all the extensive components of the prosthesis, a fundamental step in this operation,” he continued. “Fortunately, complications such as those experienced by Mrs. Edward’s following previous heart surgery are rare but are notoriously difficult to manage.” You can find more information HERE.

What do you think of these developments in 3D printed implants? If you want to share some more we might have missed, you can leave a comment in the section below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!