Can 3D printing help rescue natural reefs?

Environmental issues are becoming more and more unavoidable and the degradation of natural reefs is one of them. Natural reefs are vital for the well-being of our planet for they are one of the most varied ecosystems on Earth. However, they are quickly disappearing due to several factors that can be collectively called “environmental damage”. The answer to this problem seems to lie in additive manufacturing. According to the experts, 3D printed reefs could be the best short-term solution.

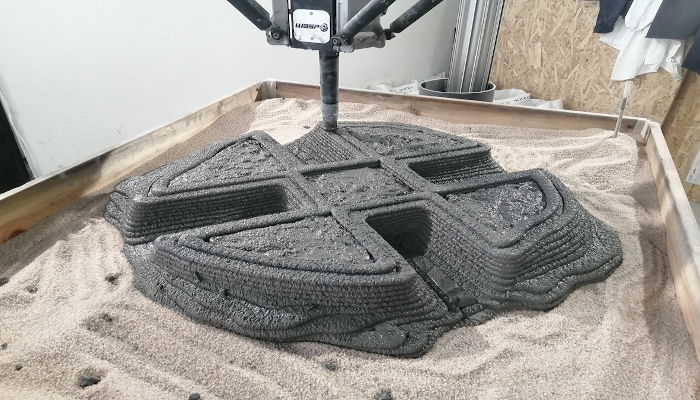

INTERREG Atlantic Area (European funding programme that promotes transnational cooperation among 36 Atlantic regions of five European countries) funded the 3DPARE project, which was born from the cooperation of several European research institutions – University of Cantabria (Spain), ESITC Caen Institute for Civil Engineering and Construction (France), University of Porto (Portugal) and Bournemouth University (the UK). The project is led by the University of Cantabria Department of Civil Engineering who specialize in 3D Printing. The 3DPARE’s goal is to deploy and then monitor the artificial reef blocks that they have been planting in the Atlantic Ocean. These reef blocks were designed and manufactured using innovative 3D printing technology and sustainable bio-receptive materials.

Credits: 3DPARE

For the sake of avoiding confusion it should be noted that artificial reefs had, in fact, been planted before. However, compared to those existing artificial reefs, whose design and structure are created from conventional materials such as concrete and steel, the solutions of 3DPARE are ecological, sustainable and specifically tailored for enhancing the biodiversity and the ecosystem in the marine environment. The optimized artificial reefs were shaped through large-scale 3D printing; the materials were developed from natural and renewable raw materials to stimulate the colonization in the marine habitat.

An interesting fact is the consistency of the selected materials in this project – after the laboratories characterized the material, they started some printing tests, which led to modifications in the mixtures to reach an adequate consistency for printing. The material had to be soft enough to be extruded but with a consistency able to keep its shape and capable of bearing the weight of the top layers of the material. After numerous printing tests more than 50 variants of mixtures of cement mortar were developed, using a cement of low clinker content, additives and recycled aggregates. Therefore, this material should reduce their overall environmental impact.

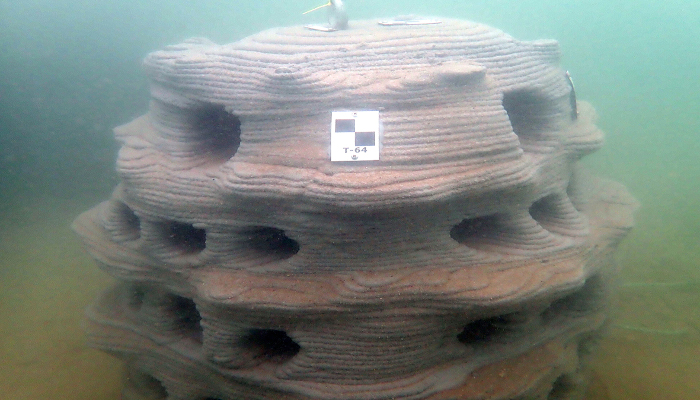

The 3D printed reef on the sea floor

The production of the reefs posed a great challenge since they are almost one-meter pieces with a weight close to one ton. In total 36 pieces were printed, with 9 remaining in Santander where they were printed and the other 27 were sent to three other “partner” locations – to Caen, Porto and Bournemouth. Once all 36 structures are immersed to the sea floor, marine biologists will have to dive regularly to assess the bio-receptivity of the 3D printed reefs. All of the reef units contain holes, tunnels, and overhangs – features that will provide suitable habitat for marine life.

You can find out more about the detailed progress of the project HERE. What do you think of the 3D printed reefs? Can it be a sustainable solution? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

fascinating stuff .I am a Ceramic sculptor and want to get a small Bronze sculpture scanned and reproduced in plastic for competition for

city Post colonial Public 3D Sculpture Bristol . U.K Need a hub with in a 40 mile radius of Mablethorpe = Lincoln # hull #Grimsby. Thank for your Help. JR.