3D printed meat, is the future of meat meatless?

Livestock farming contributes significantly to global warming through releases of methane, a greenhouse gas 20 to 30 times more potent than carbon dioxide. It contributes more to greenhouse gas emissions than the global transportation sector and almost 30% of the planet’s ice-free surface is used for this purpose. It is the top contributor to deforestation, land degradation, water pollution and desertification. On top of this, the Food and Agriculture Organisation of the United Nations (FAO) has estimated that demand for meat will increase by 70% by 2050.

If these reasons are not enough to rethink our current consumption of meat, there is also the public health and animal welfare impact. Food contamination and antibiotic resistance are just two examples of issues arising from livestock farming. And finally, the conditions animals are raised in pose a serious ethical problem – in a year alone, it’s 56 billion land animals that are raised and slaughtered for food according to the FAO and their living conditions are for the most part extremely poor. Is there a solution to these threats? Can we explore different ways of producing meat for those who wish to consume it?

What is 3D printed meat?

One way to fight these environmental issues is to stop consuming meat, or at least as much as current rates. However, many people are not ready or willing to change their ways for reasons that go beyond the purpose of this article. Even though we have seen a shift in recent years, vegan and vegetarian populations only represent a minority in Western societies, anywhere between 1 and 10% in European countries, between 5 – 7% in the US and 9.5 % in Canada. For cultural reasons, countries such as India count a very large vegetarian population, estimated to represent between 30 and 40% of their total population. Meat substitutes represent an alternative for people who wish to continue eating meat but wouldn’t mind having a product that doesn’t come from an animal. Given this fact, what can we create with the technologies that exist today? Just as they have infiltrated and disrupted almost all sectors, 3D printing technologies can greatly benefit this industry and enable the production of a new meat category. 3D printed plant-based meat will be environmentally friendlier, customisable, more affordable and positive for animal welfare.

This is not to say that there are no plant-based meat alternatives today. We can mention Beyond Meat’s ‘Beyond Burger’, ‘the world’s first plant-based burger that looks, cooks, and satisfies like beef’ you can read on their website. Or, for example, the ‘Impossible Burger’ from the Californian startup Impossible Foods. A burger made from plants that ‘delivers all the flavour, aroma and beefiness of meat from cows’. So, what does 3D printing bring to the table?

On the left Beyond Meat’s Beyond Beef, on the right Impossible Foods’ Impossible Burger | Credits: Beyond Meat (left), Impossible Foods (right)

Why is 3D printed meat so innovative?

Firstly, 3D printed plant-based meat is a very innovative enterprise. The number of people working in this field is small but the technology is very promising. Giuseppe Scionti, expert in tissue engineering and biomedicine is the founder of the Barcelona-based startup Novameat that develops the technology for 3D printing a plant-based steak. Scionti worked for over ten years on creating different tissues using bioprinting at the Polytechnic University of Catalonia (UPC) in Barcelona. In one of his projects, he created the prototype of a human ear. He quickly realised that the texture resembled the actual texture of human tissue almost perfectly. The idea of developing a proprietary technology and founding Novameat became evident, “I realised that if 3D printers could imitate human tissue that well, then I could generate a meat substitute that had the same texture as animal tissue”, he told us. “I left the university in June 2018 when I decided to patent this technology and go forward with creating Novameat.”

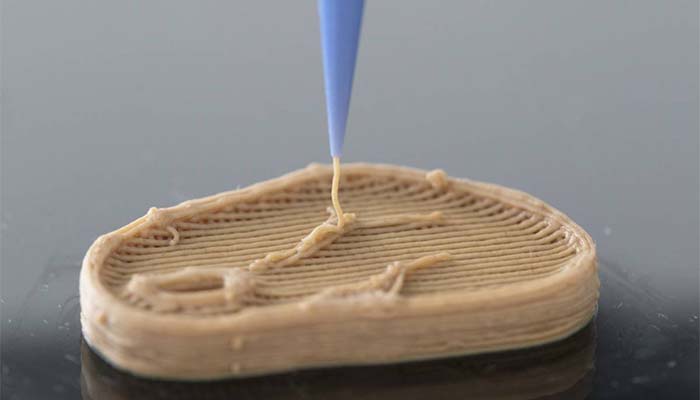

Texture is probably the biggest novelty. Giuseppe Scionti adds, “I was able to generate something that had the same texture as meat, I was able to create micro fibres that resembled not just a hamburger or a meatball but had the same texture as muscular tissue”. His creation is entirely plant-based, made out of protein powder from peas and seaweed. However, unlike other plant-based alternatives available today, it comes in the form of a steak, not ground meat (like burgers, meatballs or mince beef). In fact, there are probably four parameters that define the successfulness of a meat alternative, “We are trying to nail the four parameters that enable to imitate meat, that is taste, texture, appearance and nutritional properties. Right now, taste has been mastered with plant-based hamburgers and texture with soy extrusion, but no one has achieved the two together.”

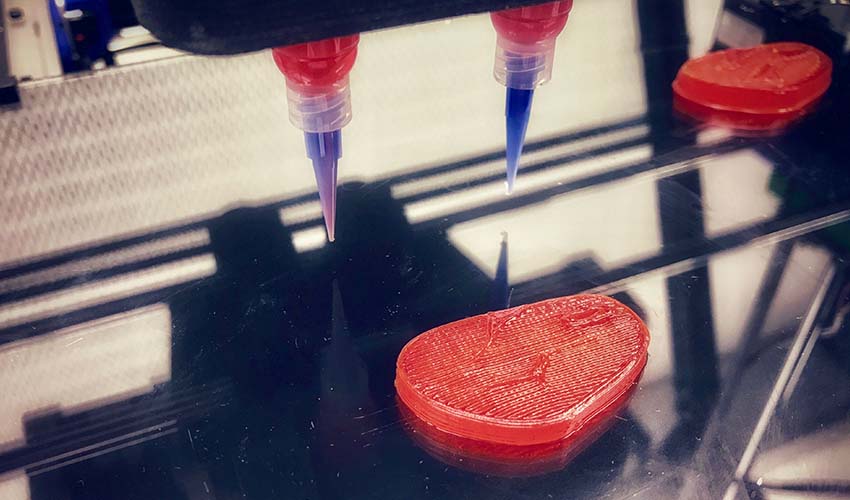

Giuseppe Scionti holds a patent on the microstrain that imitates the natural texture of meat tissue. He told El País, “I use techniques that are normally used for cultured meat, and techniques borrowed from bioprinting and adapted for use with materials for plant-based meat. The difficulty lies in reorganising the nanofibers from vegetables’ proteins to make them seem like animal proteins. First you have to study the histology of the animal tissue, how the muscle fibres are organised, and then you have to try to replicate that with plant-based ingredients that have not been genetically modified.” The 3D printer he uses was developed by the CIM Foundation, a tech-centre attached to UPC – it squirts the paste onto a printing plate following a design created by Scionti on CAD software.

The 3D printed steak being printed onto the printing plate | Credits: El País, Consuelo Bautista

Another startup working on 3D printed meat is Redefine Meat (also known as Jet-Eat), based in Israel. “It’s clear that the food industry today lacks the tools and the technologies to tackle the challenge of finding good alternatives to animals as providers of meat. Moreover, it’s clear that growing animals for food is not sustainable given the increasing population size, the booming demand for meat in Asia, and the inherent inefficiencies and pollution associated with meat production and mainly beef”, we were told by Eshchar Ben-Shitrit, CEO at Redefine Meat. The startup is working on a technology that will produce a plant-based meat alternative, more precisely steaks, roasts and stews from natural and sustainable ingredients. Their approach combines proprietary 3D printing technology, digital modeling and plant-based food formulations to deliver a new category of meat.

In terms of seeing these products more widely available, Eshchar Ben-Shitrit said, “In the past months, working with chefs and butchers, we have served hundreds of our products to unexpecting consumers. Their first response is always: I can’t believe it’s not meat and how can we get more of these? Of course, we need to work on scale, which is not a major challenge as we source raw materials that are already far more affordable than beef. Our target is not to develop a new food product, but to introduce a new food technology that will become a platform for rapid introduction of new and superior meat alternatives that do not exist today. The machines will be rolled out by 2021 to offer a wide range of capabilities beyond just producing one product. We are giving ourselves time to perfect and improve the technology so that our customers and consumers will be able to enjoy its full potential for the long-term.”

CEO Eshchar Ben-Shitrit, Redefine Meat (Jet-Eat) was selected as one of the winners of 2018 Food Accelerator Network Program competition organised by EIT (European Institute of Innovation & Technology) | Credits: bites

Once these technologies are integrated into a wider production system, they will allow for food waste, packaging and livestock to be reduced. Redefine Meat’s 3D printed meat will apparently decrease environmental impact by 95%, has no cholesterol and will be more affordable than current animal meat. Eshchar Ben-Shitrit added, “We would like to see others using these new digital capabilities to solve real problems in the food system. We would like to see an ecosystem emerging where each company takes care of different parts of the value chain, as today we need to do everything ourselves or with close partners. In five years, we believe we’ll see several types of food items transitioning to digital production, to improve products’ quality, create a better supply chain and allow for mass-customization.”

And how will consumers react to 3D printed meat? The appearance of 3D printed meat is a big determinant of how consumers will react to it explained Giuseppe Scionti. At the moment some could argue that the appearance of 3D printed meat is not yet convincing. However, by adapting the three-dimensional models to make them more complex in order to differentiate the part that imitates fat from the part that imitates muscles or other tissues, the appearance could be significantly improved. Moreover, another very interesting characteristic of 3D printed meat is that it can be customised. Therefore, it’s not just in supermarkets that we could see it supplied but also to space companies, restaurants and hospitals that need and want products adapted to their needs.

Redefine Meat’s 3D printed plant-based beef, integrated in a restaurant dish | Credits: Redefine Meat (Jet-Eat)

What about cultured meat?

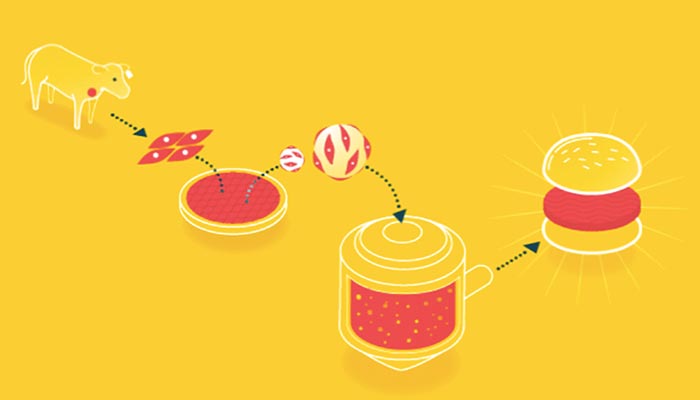

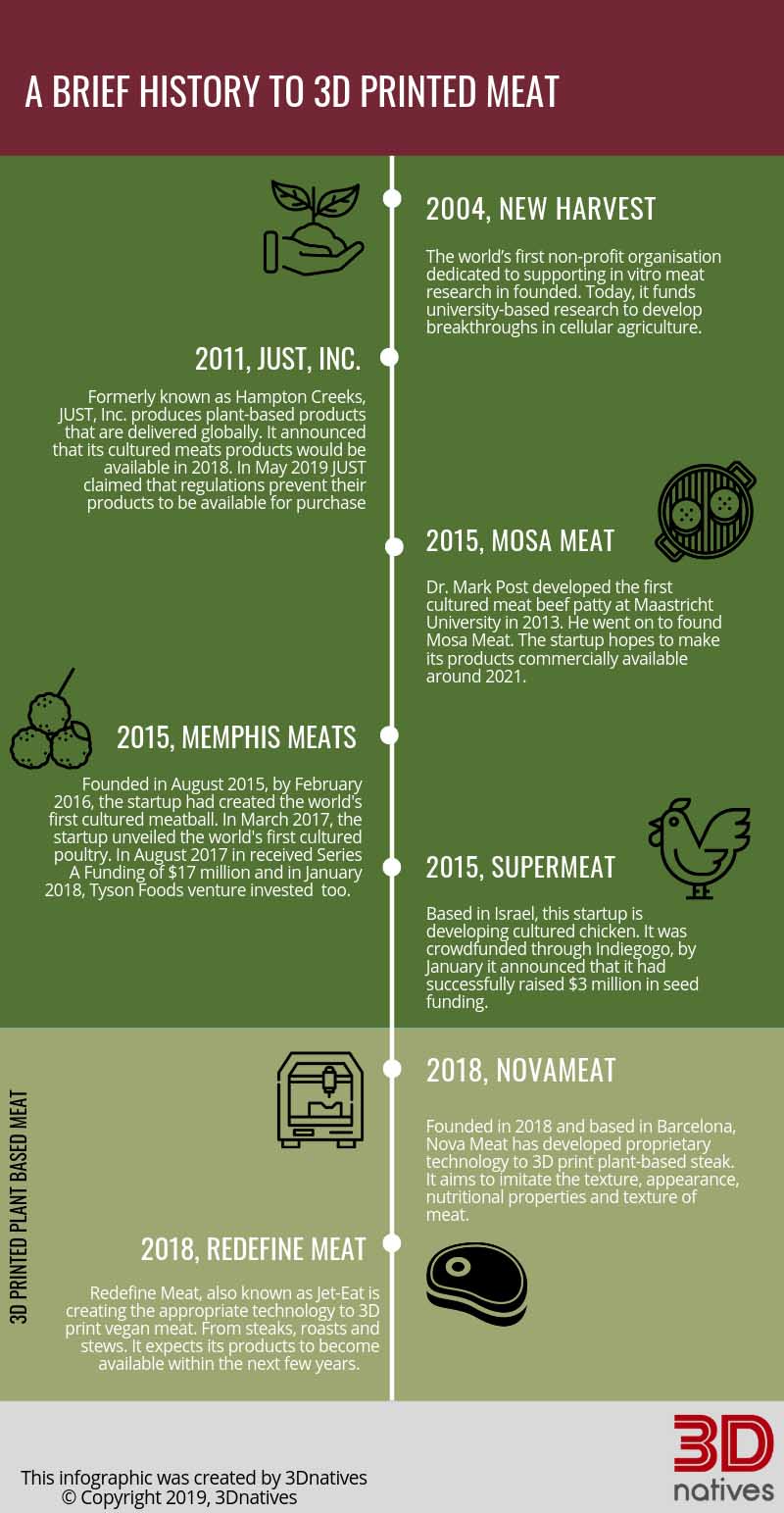

3D printed meat is not the only meat alternative that could soon surface and change the game for the meat industry. Cultured meat, also referred to as lab-grown meat, is meat that is produced by in-vitro cultivation of animal cells instead of from slaughtered animals. In-vitro cultivation of muscular fibres was performed as early as 1971 by Russell Ross, but was only popularised by Jason Matheny in the early 2000s. He co-authored a seminal paper on cultured meat production and created New Harvest, a non-profit institute dedicated to the field of cellular agriculture, in 2004.

The organisation is very important in terms of funding university-based research to develop breakthroughs in cellular agriculture. New Harvest’s mission is to propose a post-animal bioeconomy, “where animal products are harvested from cell cultures, not animals, to feed a growing global population sustainably and affordably”, they explain. Moreover, as of 2012, 30 laboratories from around the world had announced that they were working on cultured meat research. The first lab-grown beef patty unveiled to the world was created by Dr. Mark Post at Maastricht University and eaten at a press conference in London, in August 2013.

The cultured beef patty developed by Dr. Mark Post | Credits: Mosa Meat

So what is cultured meat exactly? Lab-grown meat is possible thanks to cellular agriculture – meaning that cells from a particular species and tissue type are assembled on a scaffold with serum in an environment that promotes growth. Lab-grown meat is often referred to as clean meat because it does not come with all the bacterial contamination inherent to farmed meat and because the production is significantly more environmentally friendly (generating up to 96% lower greenhouse gas emissions).

To put things into perspective, the first beef patty took 2 years to make and cost around $330,000, funded by Sergey Brin, the co-founder of Google. Three years and a half later a report revealed that for the same patty, the price had dropped to $11.36. And recently, the San Francisco startup Memphis Meats is producing clean meat for $40 per gram, about a fifth of the cost from a few years ago. The end goal of course is to produce clean meat that is cheaper than conventionally produced meat. A goal that could be met according to experts within the next ten years if the appropriate support and funding is given to clean meat research – which New Harvest would argue is still lacking.

Because cells can only grow about 0.5mm thick in culture, it is easier to grow ground meat than something thick like a steak explains New Harvest | Credits: New Harvest

Will 3D printing technologies have an impact ?

Just recently researchers from Tel-Aviv bioprinted a tiny human heart using a patient’s own cells and biomaterials – they were able to bioprint complex vascular networks and capillaries. It seems rather natural that bioprinting technology is advanced enough to be able to create meat from animal cells.

We spoke to Meera Zassenhaus, Community Engagement Associate at New Harvest who told us, “The application of bioprinting to cellular agriculture is uncharted territory. However, just because nothing has been done to unite the two just yet doesn’t mean that kind of interdisciplinary work isn’t extremely promising. I think a lot of scaffold materials could be 3D printed. There hasn’t been much research into agricultural applications of traditional medical research because there isn’t a funding stream for that kind of work. That’s why we exist, to provide that funding stream at the academic level. But the same funding problem exists for those who want to explore bioprinting in a cell agriculture context.” Giuseppe Scionti also told us that his technology could serve as a scaffolding technology to cultured meat companies.

Meera Zassenhaus added, “Unlike organs, meat doesn’t have to be successfully integrated back into a living body, so it seems like a reasonable starting point for a lot of biomedical innovations. I don’t know of anybody that has bioprinted meat but that doesn’t mean it hasn’t been done yet. It seems like it would be a lot faster and more efficient than bioprinting a heart. If we can 3D print a heart, I don’t see why we couldn’t do the same for meat.”

The team at Memphis Meats preparing dishes using their cultured meat (chicken and beef) | Credits: Memphis Meats

Where are these meat alternatives headed?

We are now certain that 3D printed plant-based meat is on its way – it is only a matter of time before production can be scaled up. As for clean meat, the startup founded by Dr. Mark Post in 2015, Mosa Meat, expects to bring cultured beef burgers to the market within the next few years. The biggest scientific challenge they explain is “developing a replacement for fetal bovine serum. We cannot use this in future, both because it’s incompatible with our animal welfare standards, and also because it’s inherently unsustainable given cultured meat itself will reduce the herd of cows worldwide. So far, we’ve achieved serum-free medium that works, but we still need to optimise it.” Moving forward, production will have to be scaled up and the price brought down to a competitive level. In 2015, two other startups launched in order to work on commercialising cultured meat including Memphis Meats, based in California and SuperMeat, based in Israel. Both companies have received serious funding in the last years. Memphis Meats expects to bring its products to market in 2021.

Winston Churchill declared in 1931, “Fifty years hence, we shall escape the absurdity of growing a whole chicken in order to eat the breast or wing by growing these parts separately under a suitable medium”. We are certainly moving in this direction, and this is good news for our planet and animals.

*Cover Picture Credits: Novameat (The first prototype of their 3D printed plant-based steak after being printed)

You can find more information on the following websites: Novameat, Redefine Meat (Jet-Eat), New Harvest, Mosa Meat and Memphis Meats.

Would you try 3D printed plant-based meat? What about cultured meat? Let us know in a comment below or on our Facebook and Twitter page! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

The future of meat is not meatless. Meat alternatives are meatless. But meat will still be meat — just 3D printed. I’m holding out for a delicious, juicy steak that’s real and slaughter-free. Now, beef ribs — that’ll be a whole different kind of challenge.