3D Printed Lung Tissue Used to Analyze the Impact of Toxic Fumes on Humans

Throughout the day, we are surrounded by a variety of odors, some of which can be harmful to our health. Indeed, chemicals such as ammonia and chlorine can be particularly dangerous. The people most at risk are those who work in ports and factories, where incidents can occur. These two substances are still among the most widely transported in the USA in particular, making their management and handling delicate and potentially dangerous.

To better understand the hazards associated with certain chemicals, the Science & Technology Division of the U.S. Department of Homeland Security and its Chemical Safety Analysis Center (CSAM) have collaborated with the Wake Forest Institute for Regenerative Medicine (WFIRM). Together, they are working to reduce the effects of exposure to these substances. They have developed 3D-printed human lung cells and tissues on microchips to be used for in-depth studies on what is harmful to our health.

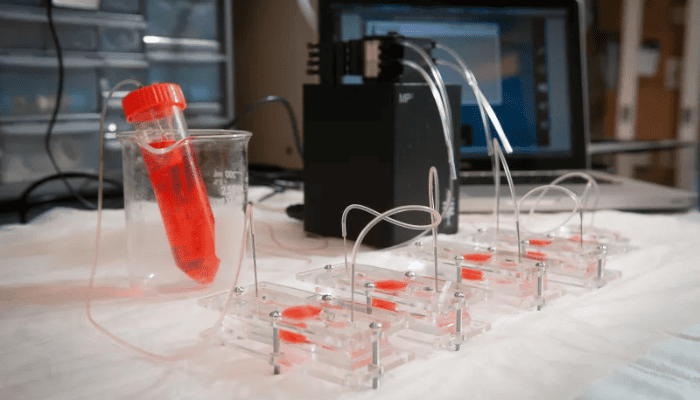

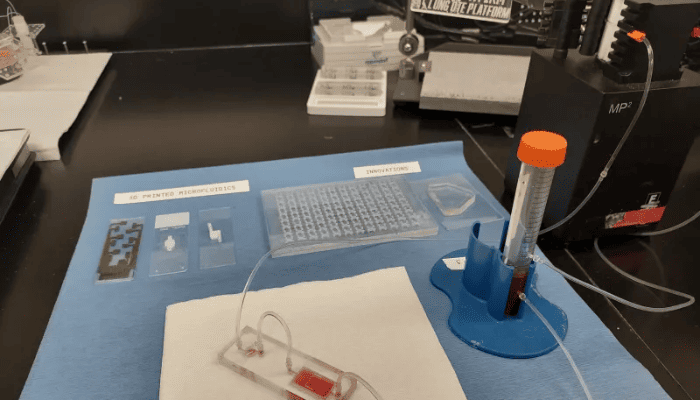

Multiple Organ-on-a-Chip slides that are being used for testing

3D Printing to Recreate and Study Lung Tissue

Theresa Pennington, project manager, emphasizes the importance of their research: “The Organ-on-a-Chip studies that we are conducting with our partners at the Wake Forest Institute are incredibly important.” Indeed, Wake Forest’s 3D printer for organic lung tissue marks a great advance on traditional methods.

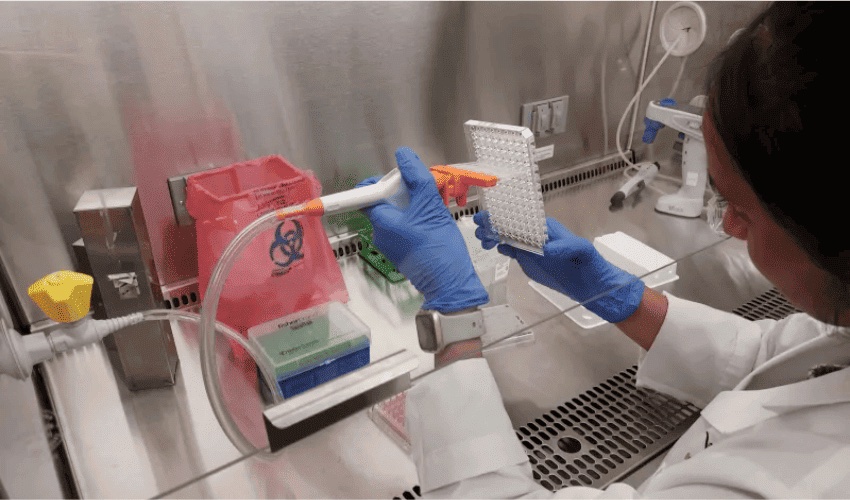

Rabih Jabbour, principal investigator at S&T CSAC, further explains, “With Organ-on-a-Chip, we are able to design a lung tissue system using robotic technology. We are able to 3D bio-print a lung model that mimics the microenvironment of a real human model. And it is living human tissue. So, in this case, we are directing a robot to do it, so we eliminate the possibility of human operator error. A robot always wins in terms of precision.”

The team follows all the legal and ethical rules for using donor cells. These cells are placed in a 3D bioprinter, which transforms them into tissue resembling a real human lung. “The entire microchip is only 1×2 inches or even smaller,” explains Dr. Sean Murphy, WFIRM project co-lead. “Within a permeable membrane lies the new OTE, and just like a real lung, it has tiny tubes inside it where air travels. These tubules are around 60 microns across, or about the thickness of a human hair. Air that contains the toxic chemical vapors is then pumped through those tubes to simulate as if someone was inhaling the fumes. That’s when the toxin interacts with the cells inside the tubes.”

The Organ-on-a-Chip model enables tests to be carried out in a stable, reproducible environment, reducing the need for animal experiments. It offers greater accuracy in simulating human physiology, unlike animal models, whose reactions may not match those of humans under the same conditions. But what is the main aim of this research?

The aim is to create a detailed database on hazardous chemicals and their toxic effects. This information will be essential to help authorities prepare for and react to accidents or attacks. Better understanding the impact of toxic substances is at the heart of this research. It aims to detect possible exposure and analyze the effects on health, both immediate and long-term. These advances could also help doctors choose the best treatments for their patients. You can find out more HERE.

What do you thiink of these 3D printed lung tissues? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! If you are looking for more 3D printing in medical & dental content, check out our dedicated page HERE. Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*All Photo Credits: Wake Forest Institute for Regenerative Medicine (WFIRM)